rusty428cj

Rusty Gillis

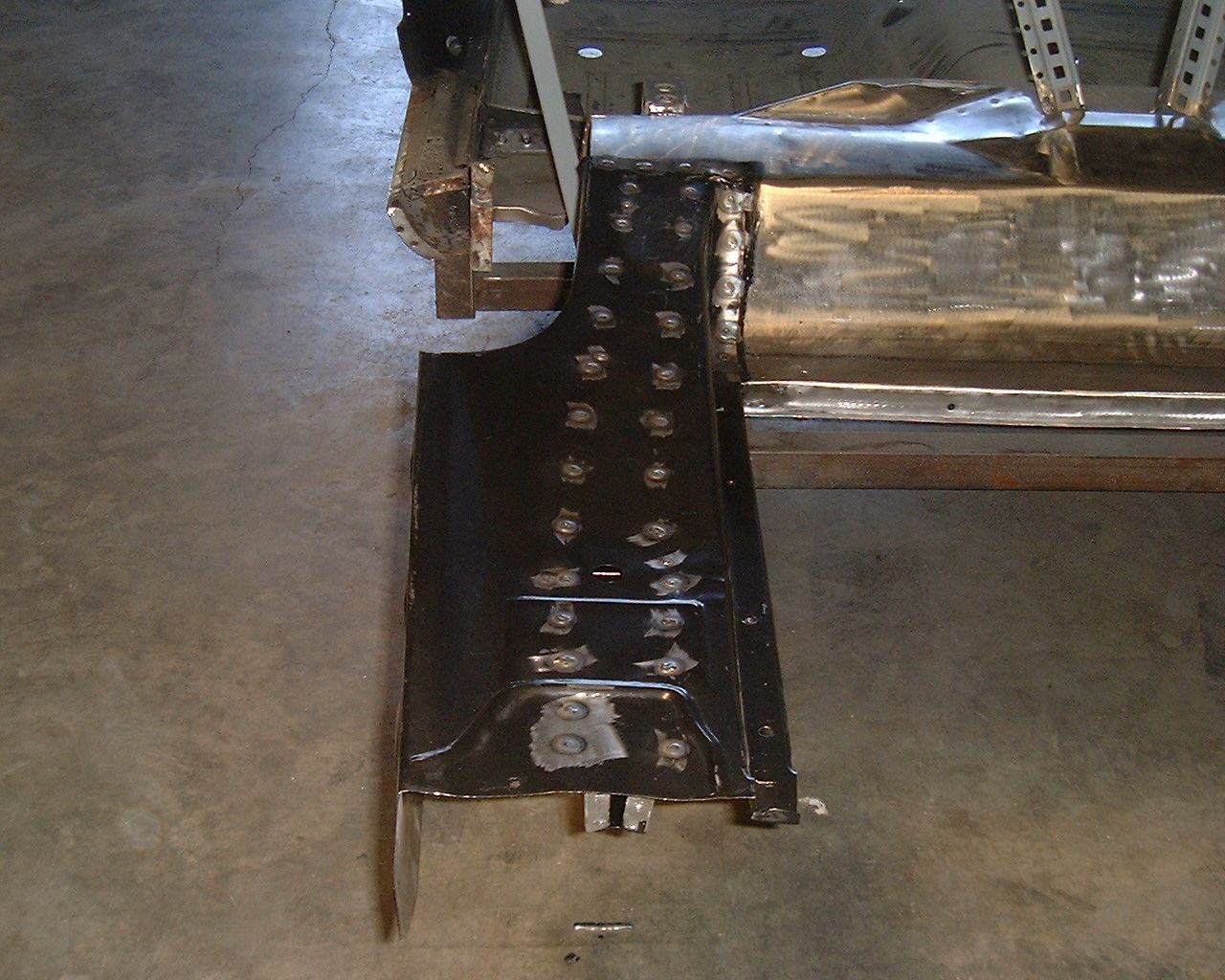

We have a new rear panel so Brian removed the old one. This will save a lot of time.

After the panel was removed he had to make a patch for the front trunk floor

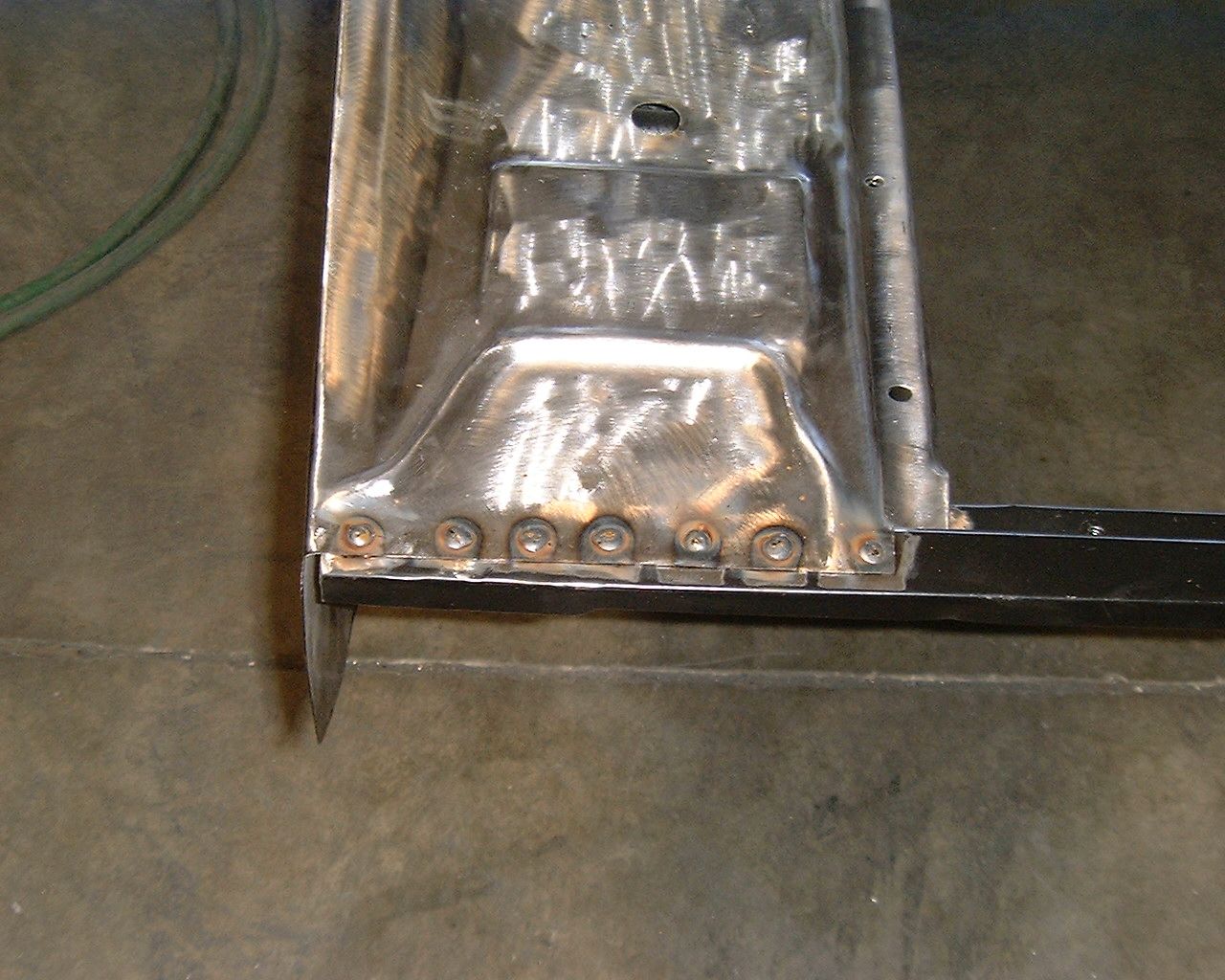

After Brian cleaned up the plug welds

After the panel was removed he had to make a patch for the front trunk floor

After Brian cleaned up the plug welds