You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1969 Plymouth Barracuda Restoration Thread

- Thread starter MJM

- Start date

MJM

Promoted Users

I would use a flat piece of wood as a dolly and hammer from the inside, its probably already stretched. You don't need the washer, but will probably need to shrink a bit.

Thank you for that tip. I tried the wood and that did the trick, along with a few lite tap tap tap taps, lol. Nobody's going to see it since the bumper covers it but, it was good practice to try.

Thanks again.

Before

Another

After with wood block

Another

Another

Last edited:

MJM

Promoted Users

Damn, excellent job of it.

"Damn" coming from you is quite the compliment, thank you. I know some may think I grinded it flat, I did not, and that can be seen by the material thickness at the bolt hole.

Just finished welding up filler holes around the headlight opening. I wish I could get behind it so I could planish the welds but, there's no access so, it'll get a skim coat of fiberglass filler.

Holes to be welded up

After

Last edited:

'68 Coronet R/T

Oldtimer

Looks great!

MJM

Promoted Users

A little more progress done. I'll be hanging the fenders and doors in about a week. Just waiting on a bolt order to mount them.

Now that I have a better understanding for welding sheet metal thanks to MP&C, I've undertaken some delicate welding items that I would have never done for fear of royally screwing it up.

First up is the drivers door handle.

Mounting hole for the door handle stud and nut is broken, and the metal is torn.

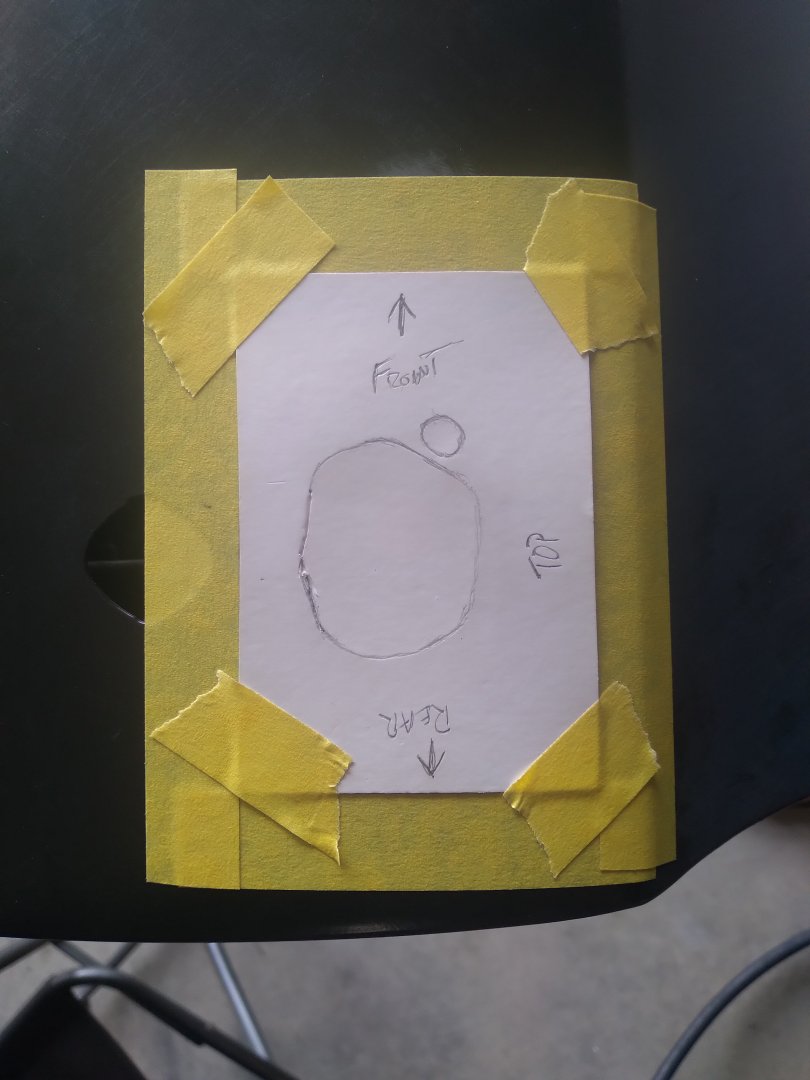

First up was making a door pattern of the existing holes.

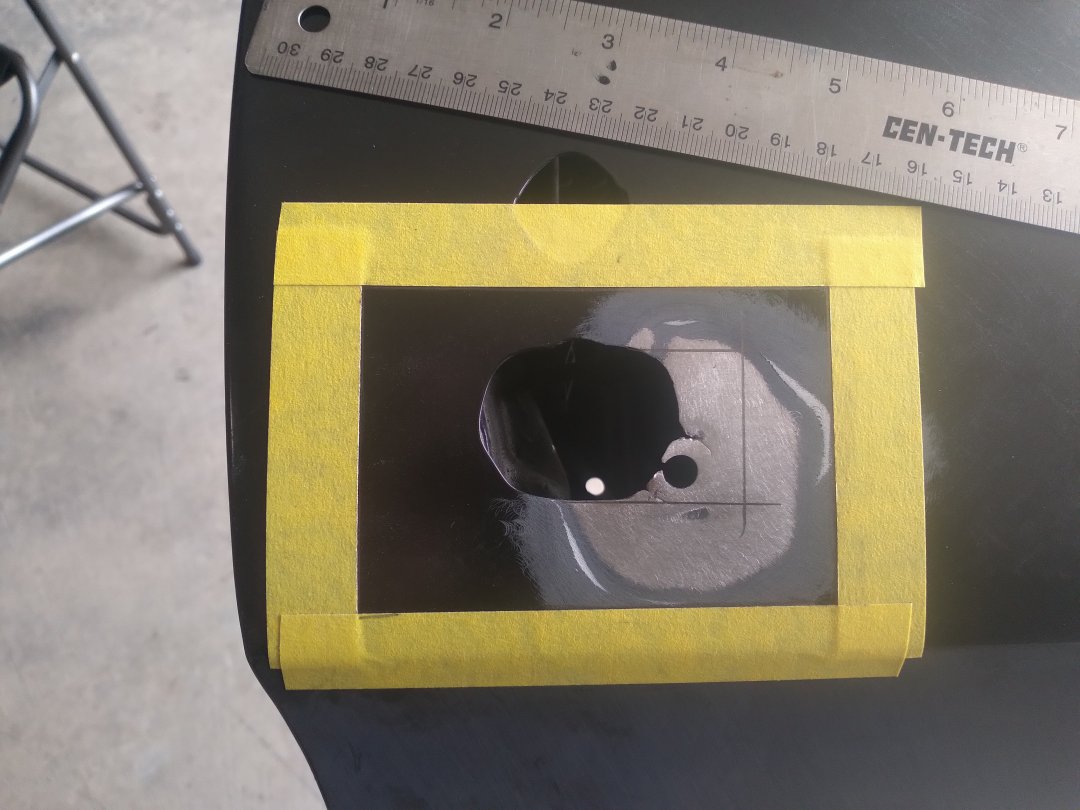

Laying out the existing metal to be cut out.

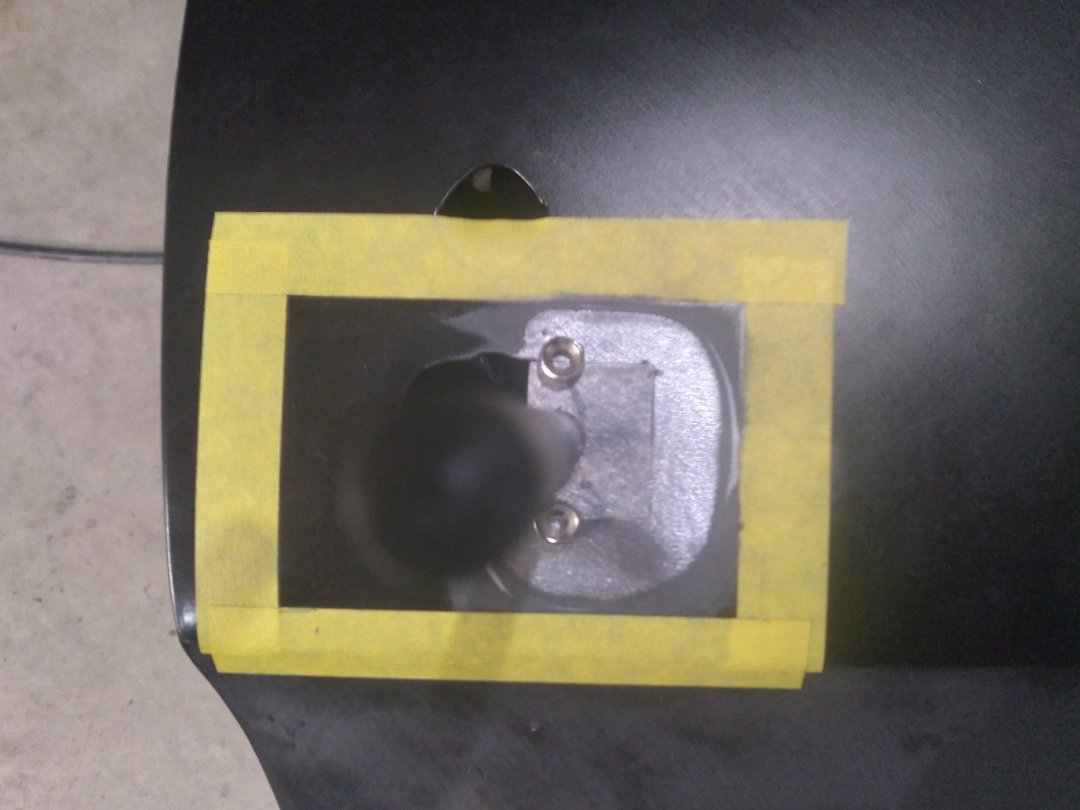

Metal cut out and new sheetmetal filler piece fitted.

Started tac welding, grinding, planishing and repeat until fully welded.

Continued on next reply below......

Now that I have a better understanding for welding sheet metal thanks to MP&C, I've undertaken some delicate welding items that I would have never done for fear of royally screwing it up.

First up is the drivers door handle.

Mounting hole for the door handle stud and nut is broken, and the metal is torn.

First up was making a door pattern of the existing holes.

Laying out the existing metal to be cut out.

Metal cut out and new sheetmetal filler piece fitted.

Started tac welding, grinding, planishing and repeat until fully welded.

Continued on next reply below......

Last edited:

MJM

Promoted Users

Some may remember a gap issue I had with the door to front fender and cowel.

The front of the door need to be re-shaped, and the side of the cowel needed to be refined for a straight gap line.

As soon as I bolt the fenders and door back on, I'll know if I corrected the issue.

Existing condition

First up was adding some welds to the outter edge of the door to even out the gap between the fender and door at the top.

Welds dressed and epoxy primed.

The front of the door need to be re-shaped, and the side of the cowel needed to be refined for a straight gap line.

As soon as I bolt the fenders and door back on, I'll know if I corrected the issue.

Existing condition

First up was adding some welds to the outter edge of the door to even out the gap between the fender and door at the top.

Welds dressed and epoxy primed.

MJM

Promoted Users

That's some excellent Robert like repairs.

Damn, there are two of you now, ha........awesome results.

LMAO........I don't have a tenth of the skills Robert has but, that was a very nice compliment. I usually can accomplish a task with expert advice. It really comes down to how much effort someone is willing to put in with the advice given. I will go that extra mile especially when someone takes their time to explain how to do something. It's my way of saying thanks for their help

Last edited:

JimKueneman

Mopar Nut

Wow. Excellent work. I think Robert’s Spirit Hawk is roosting near you now.