MP&C

Member

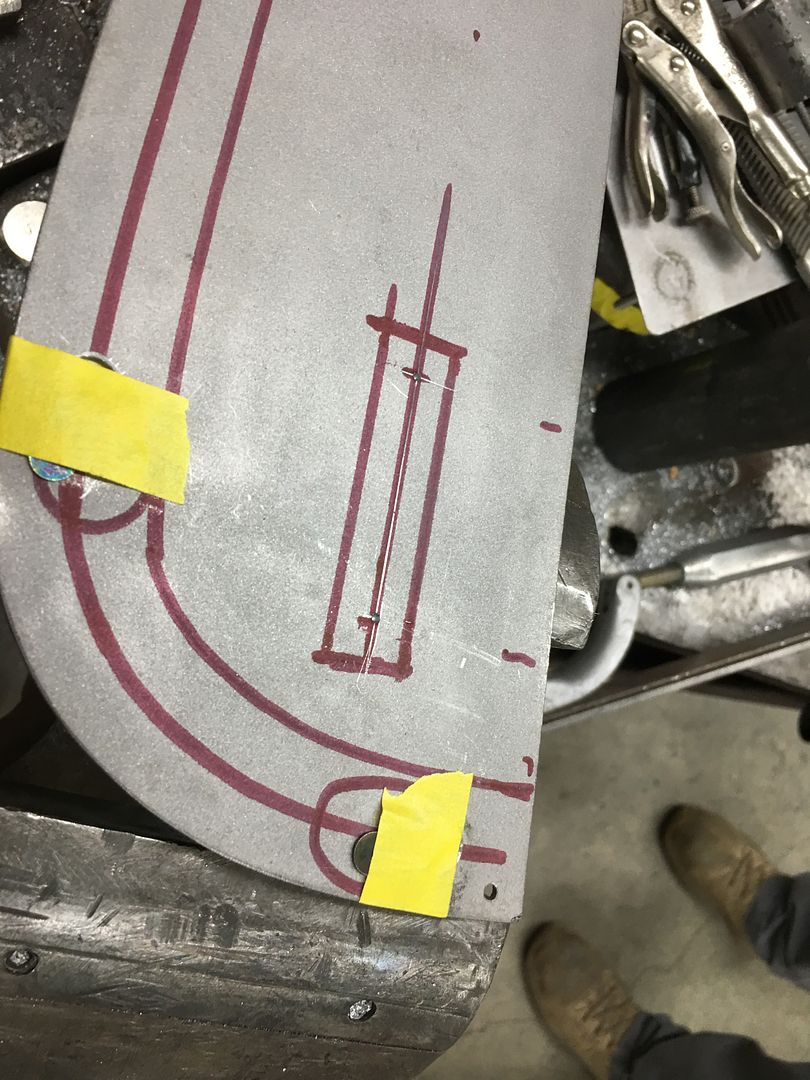

Another part we're adding due to the length of this car is a second interior light. We chose to go with the original version, so here's a factory mount, spot welds ground out from the back side of the included section of roof crossmember. Then it will get media blasted, epoxy primed, and plug welded in place.

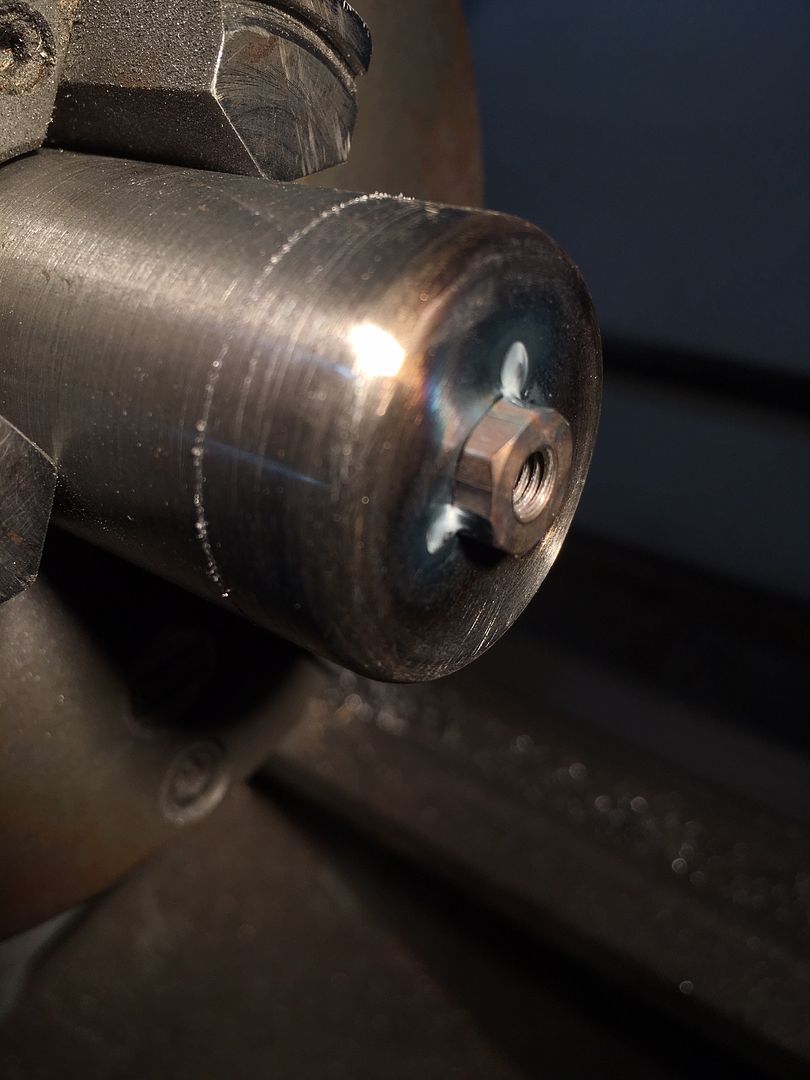

We got the baffle/lower radiator mount plug welded in place...

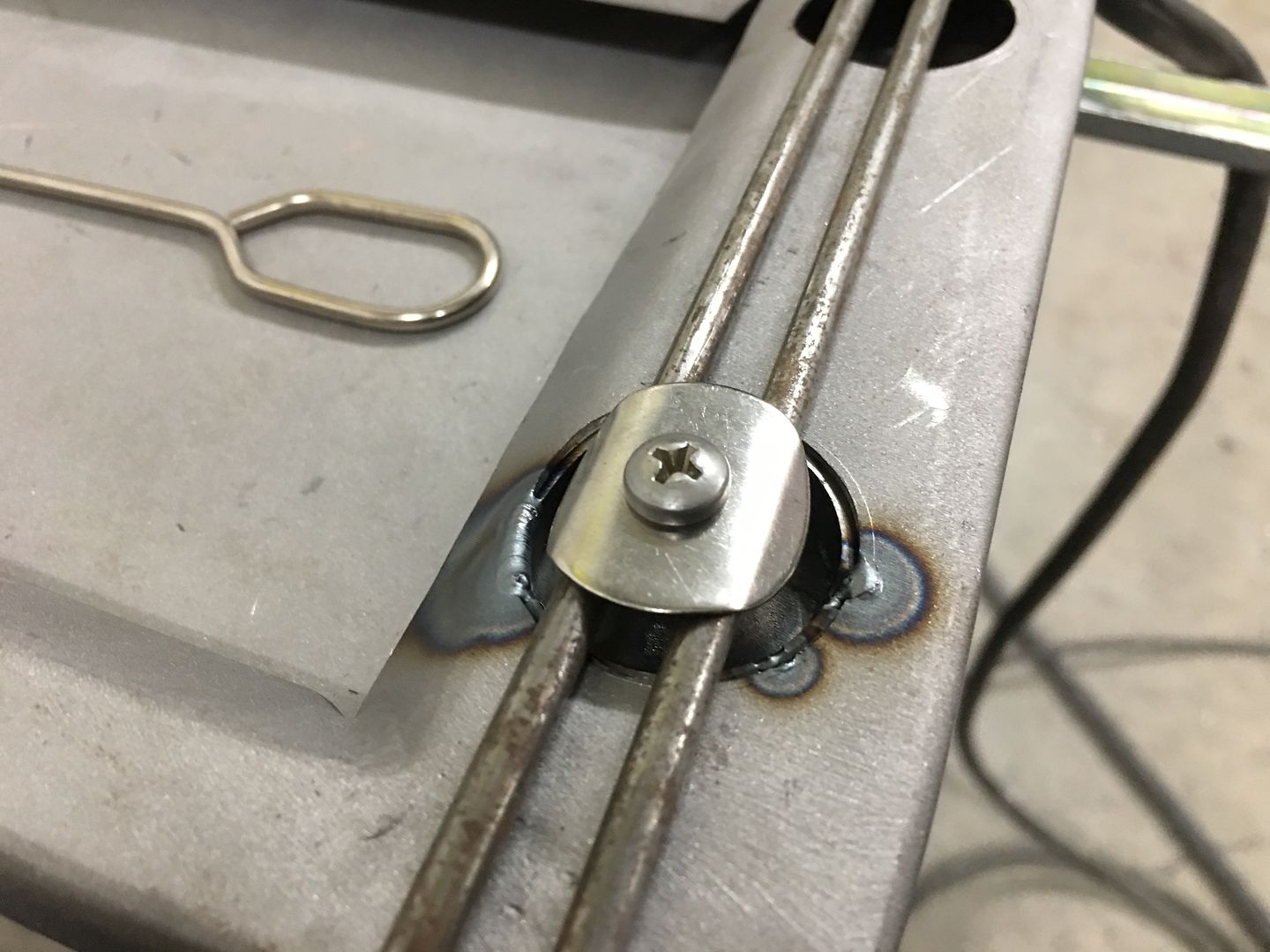

...and the rubber edge trim for our lower radiator mount added.. The "final" version will include weather strip adhesive to keep it locked in place on the radiator.

Needs to be pressed in a little more but this is the idea...

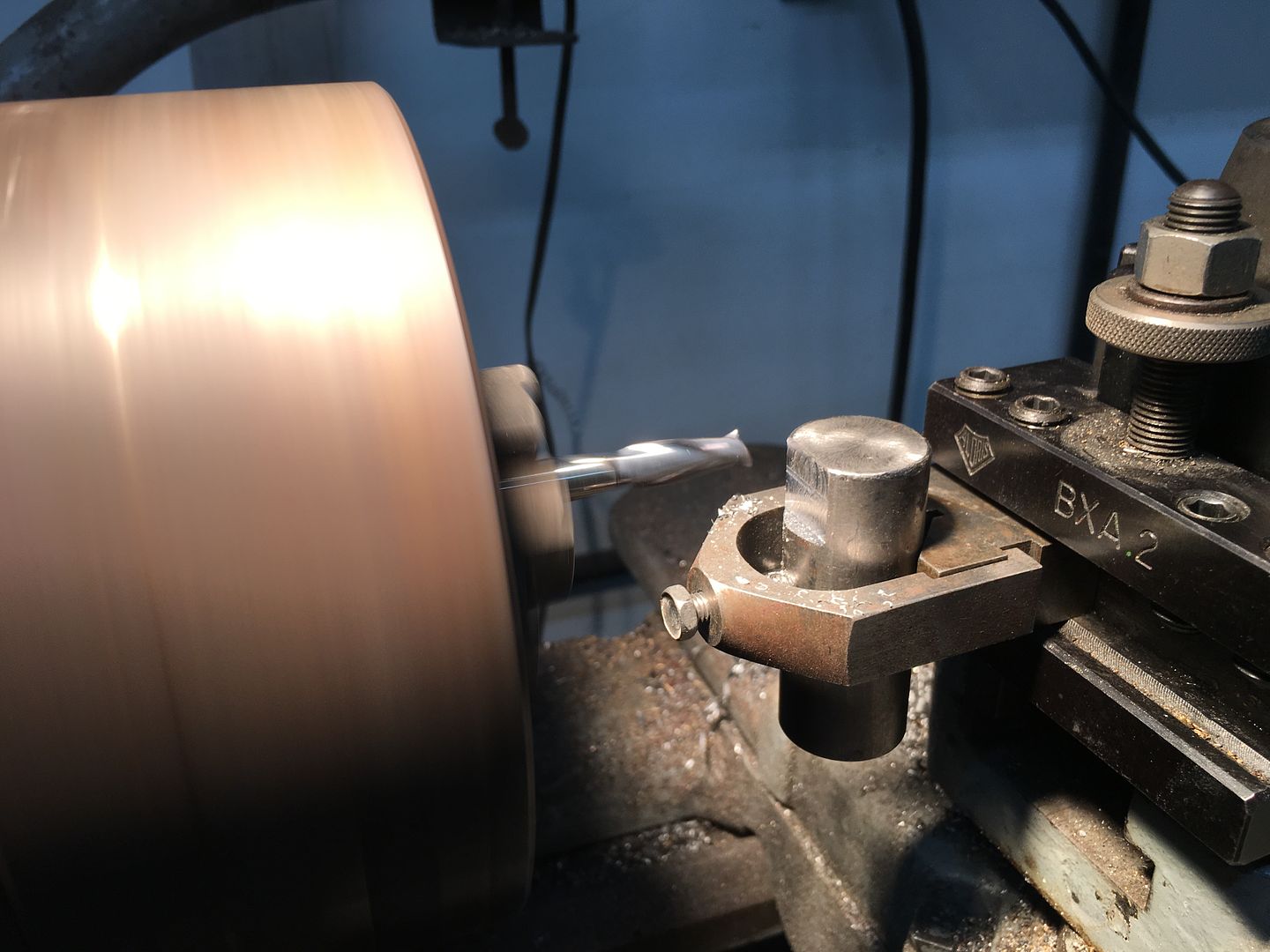

Side baffles for the core support were trimmed on the inside (for our larger opening) , new mounting slots added, and access holes opened up..

Lower radiator hose clearance to the battery support bracket...

We got the baffle/lower radiator mount plug welded in place...

...and the rubber edge trim for our lower radiator mount added.. The "final" version will include weather strip adhesive to keep it locked in place on the radiator.

Needs to be pressed in a little more but this is the idea...

Side baffles for the core support were trimmed on the inside (for our larger opening) , new mounting slots added, and access holes opened up..

Lower radiator hose clearance to the battery support bracket...