MP&C

Member

Thanks crash!

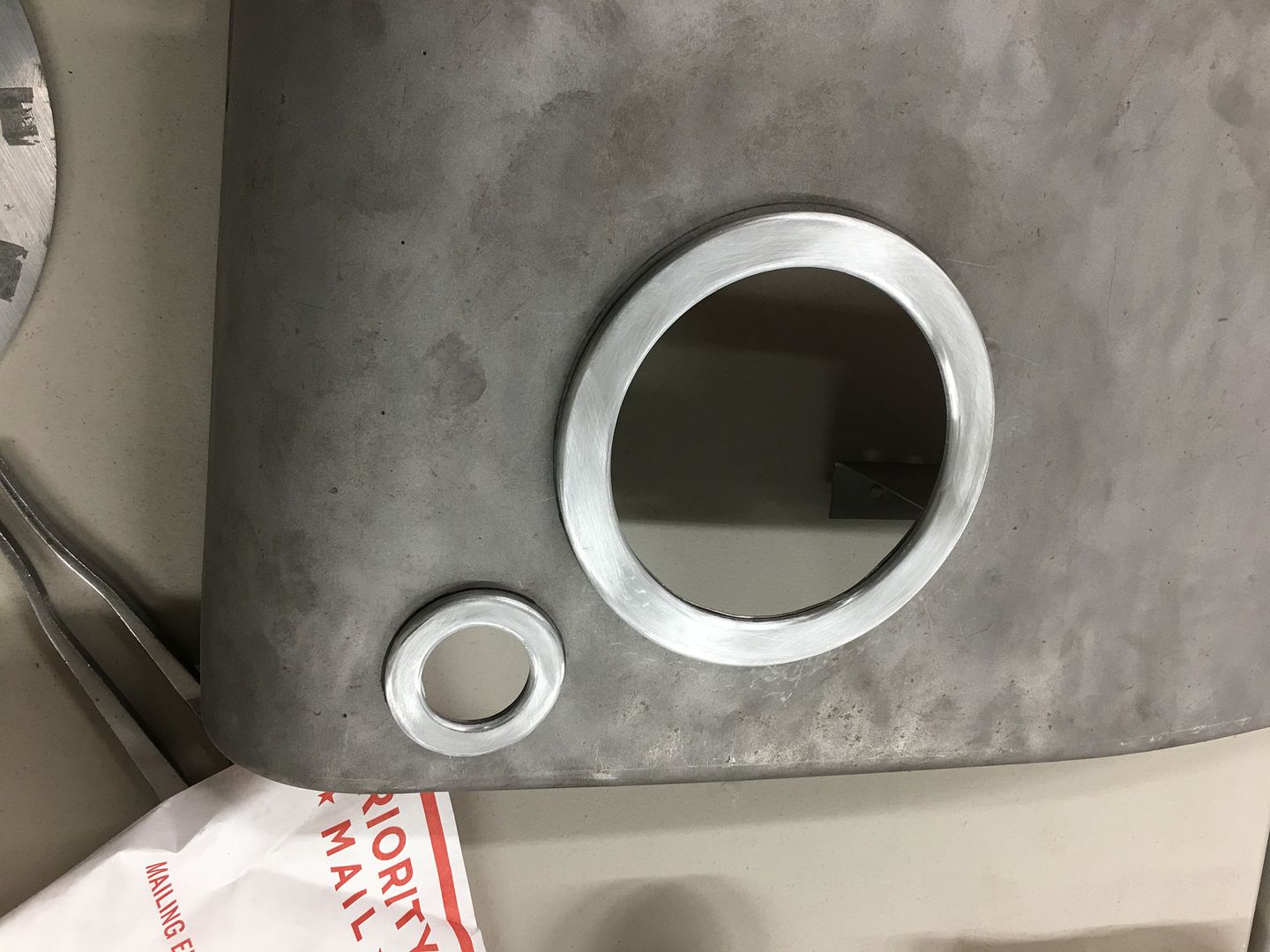

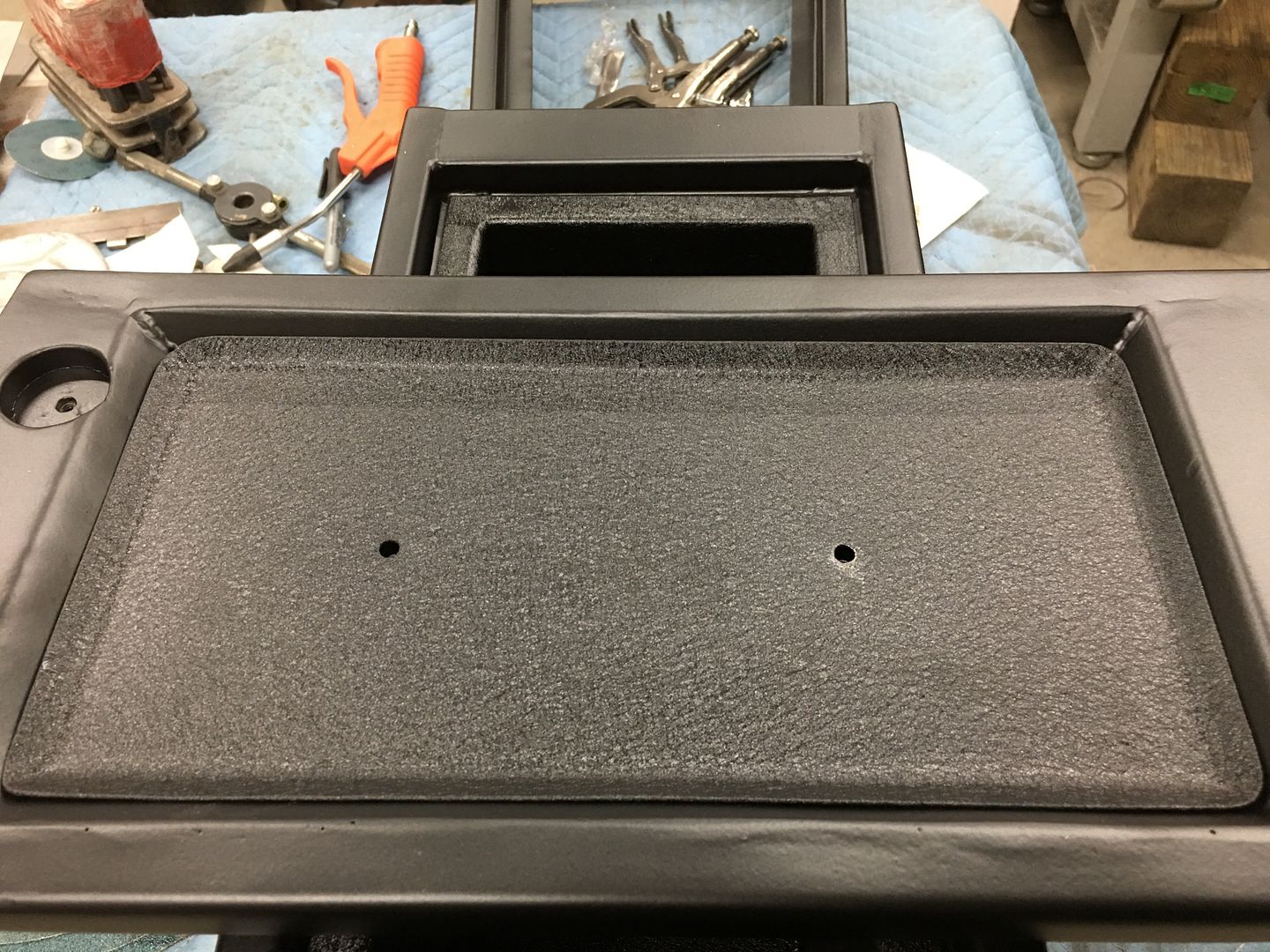

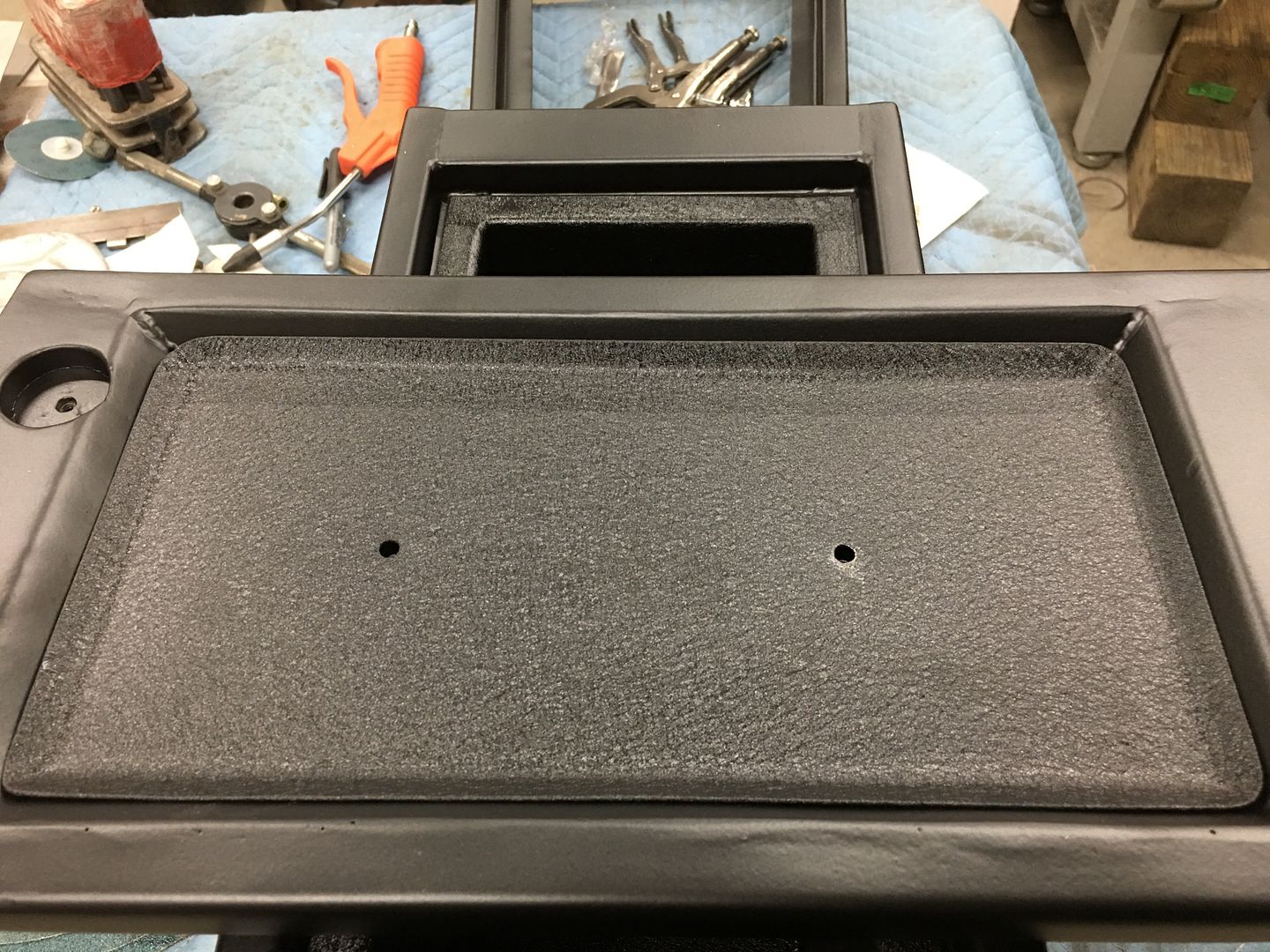

Picked up the console from the powder coater, the outside was done in satin black and will be covered in upholstery, the inside parts were done in wrinkle finish, this will be their "covering"

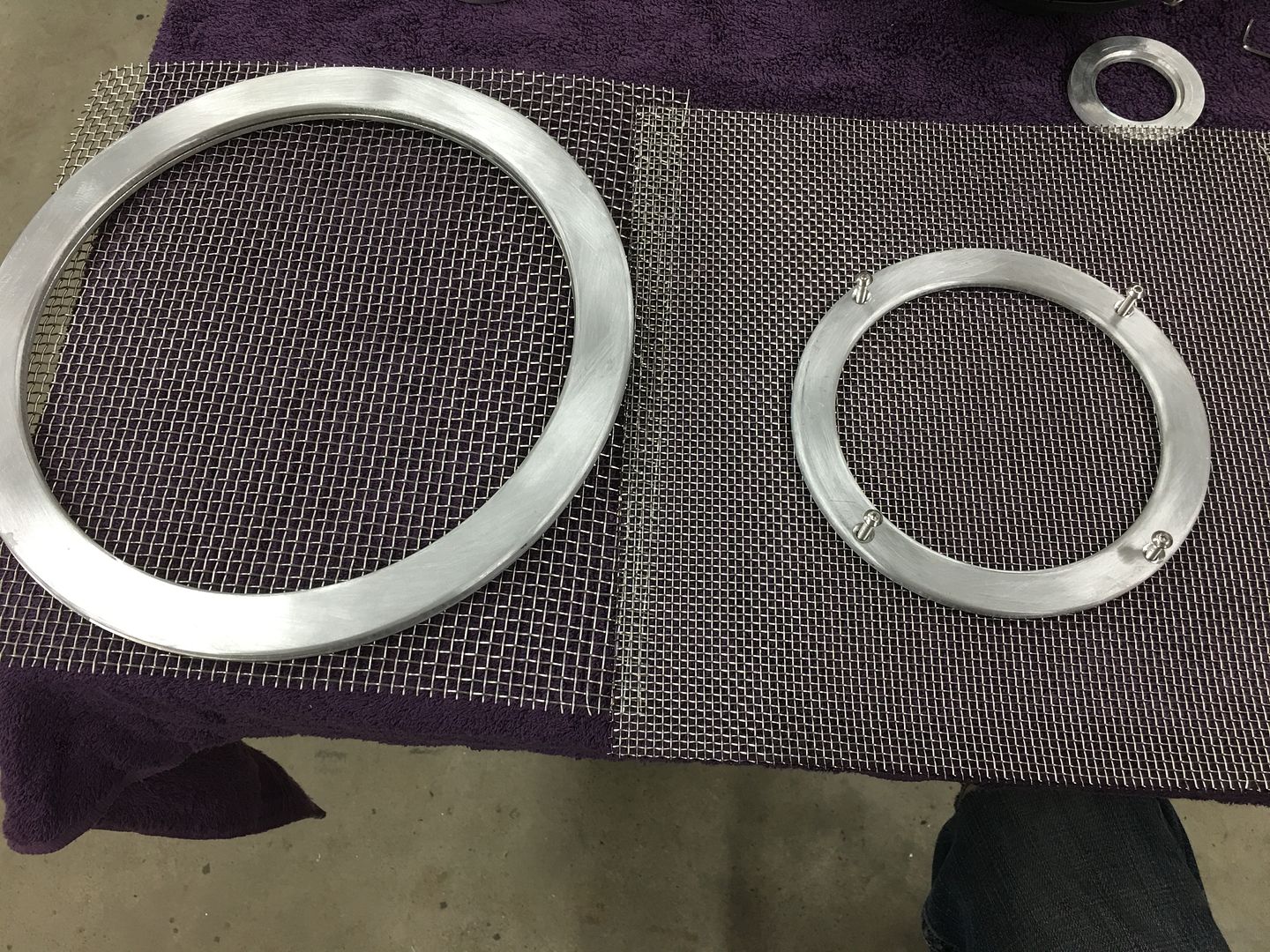

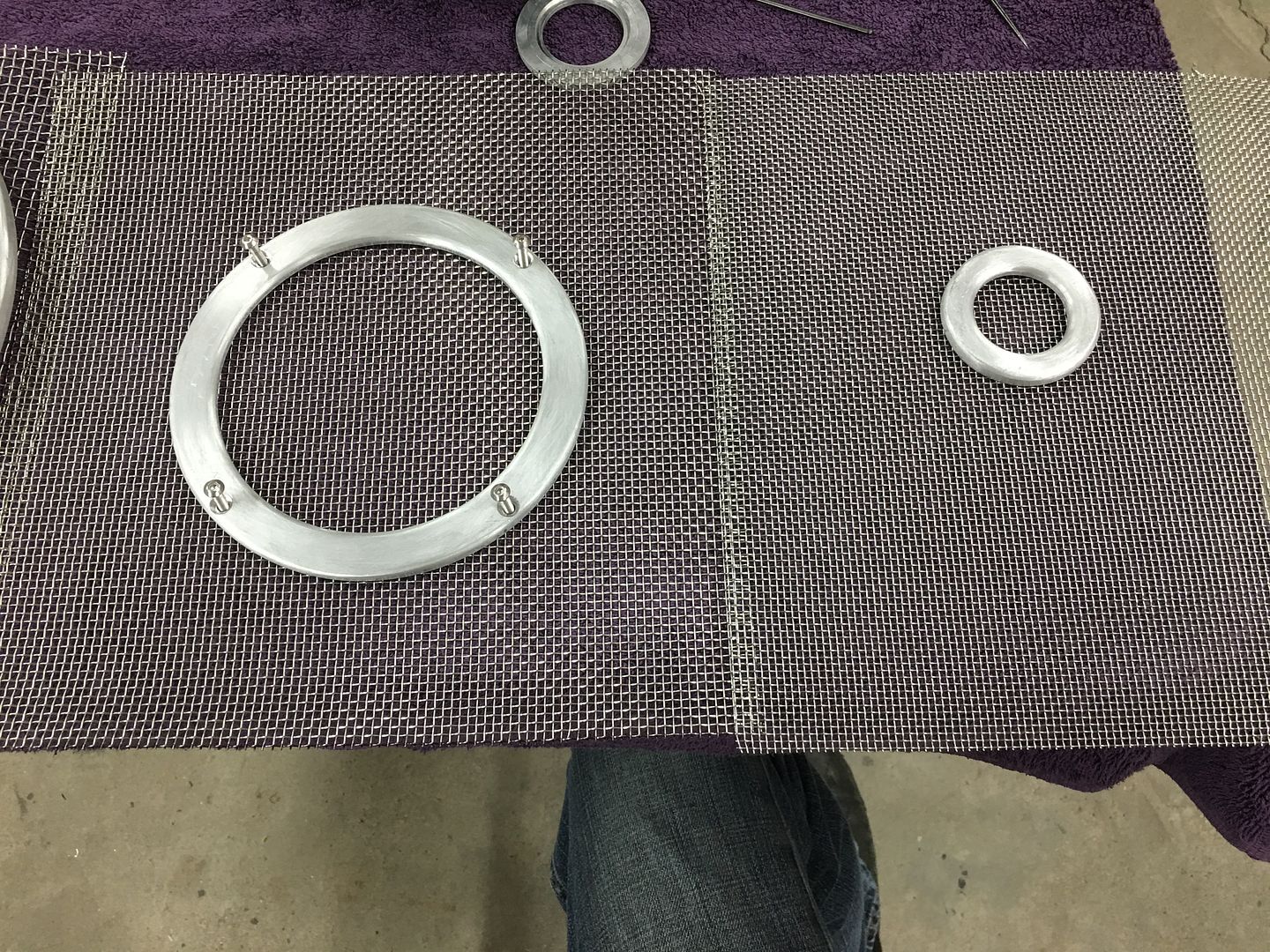

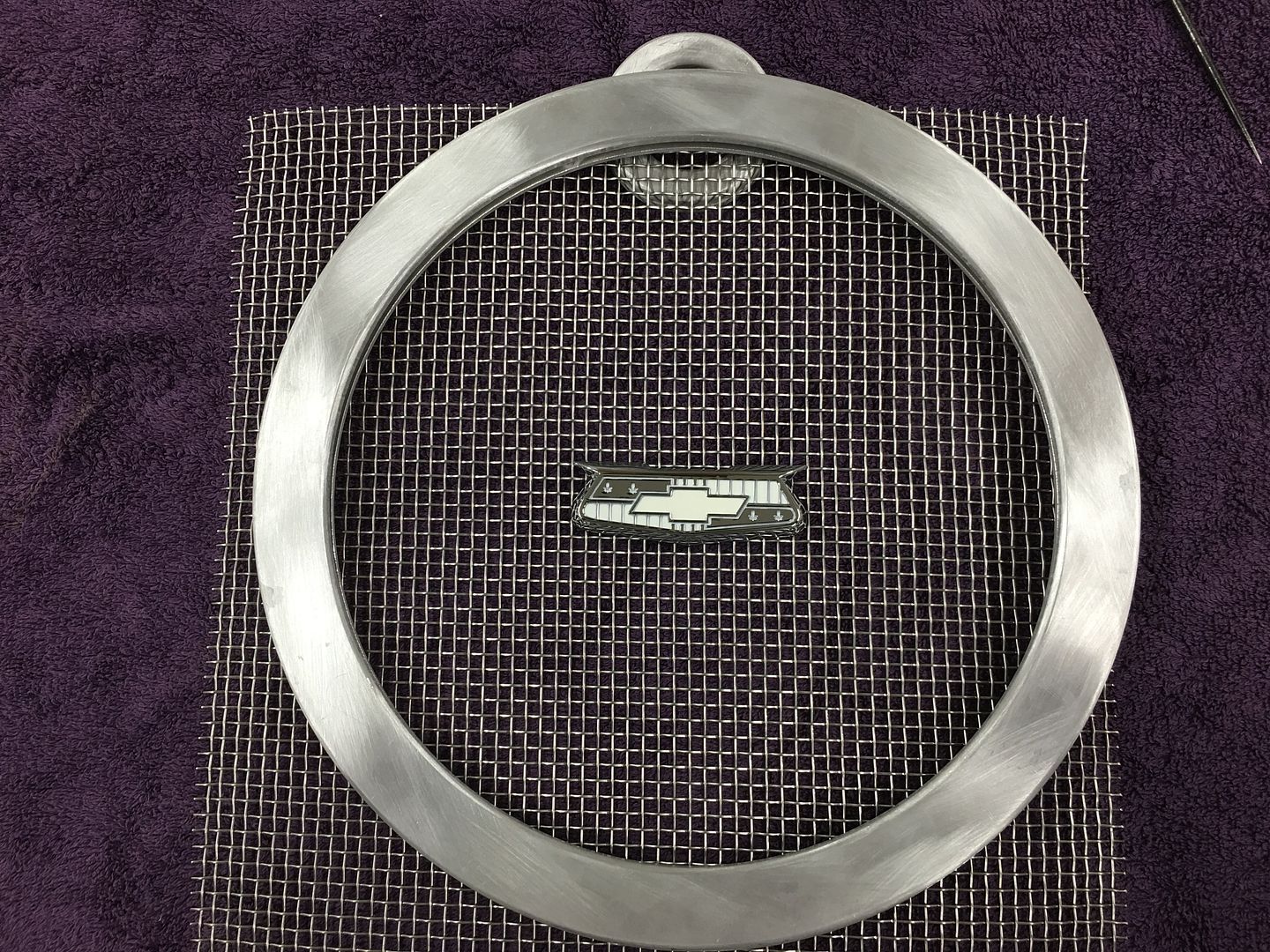

Tonight we worked on some stainless for our seat belt escutcheons..

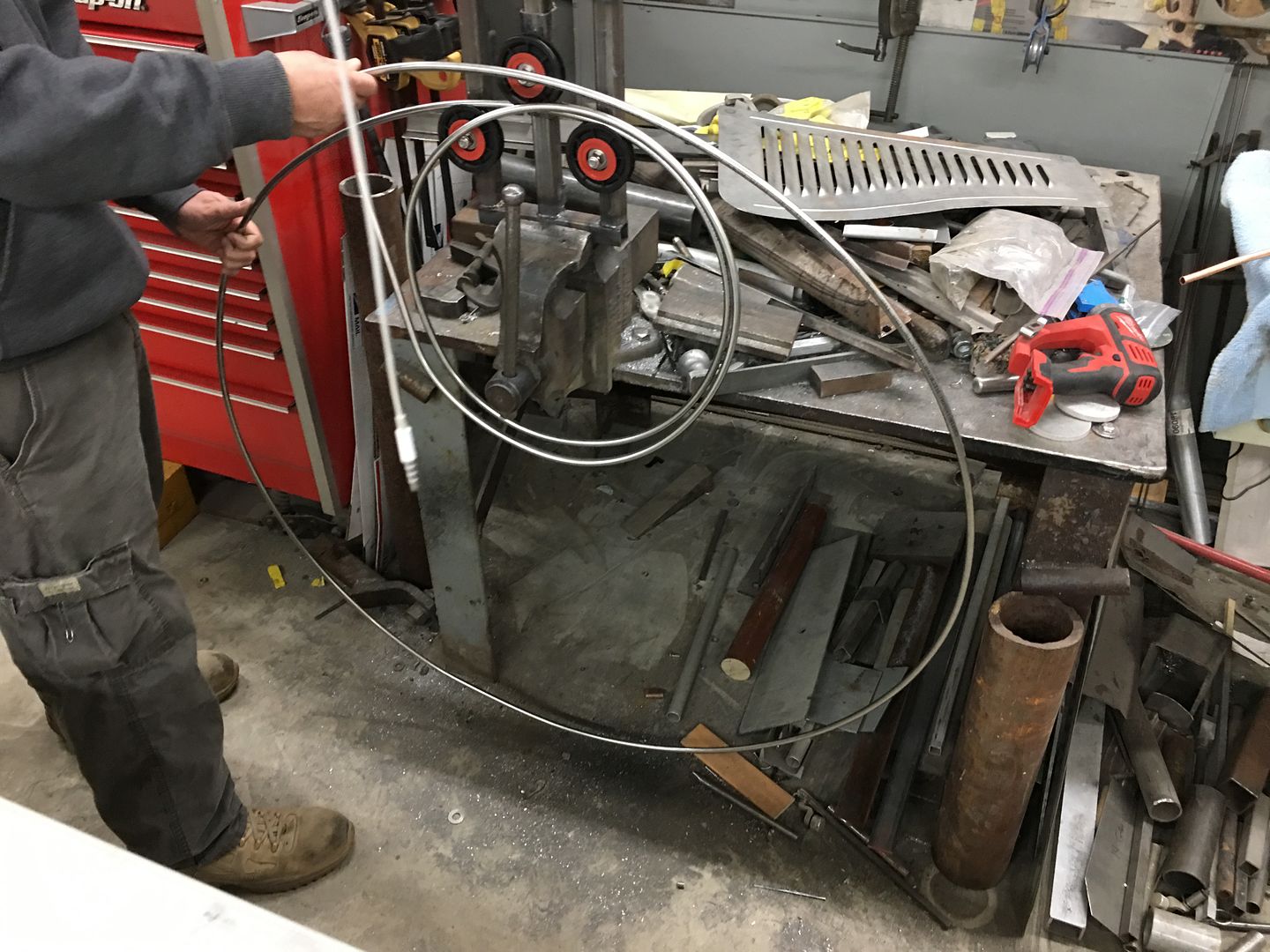

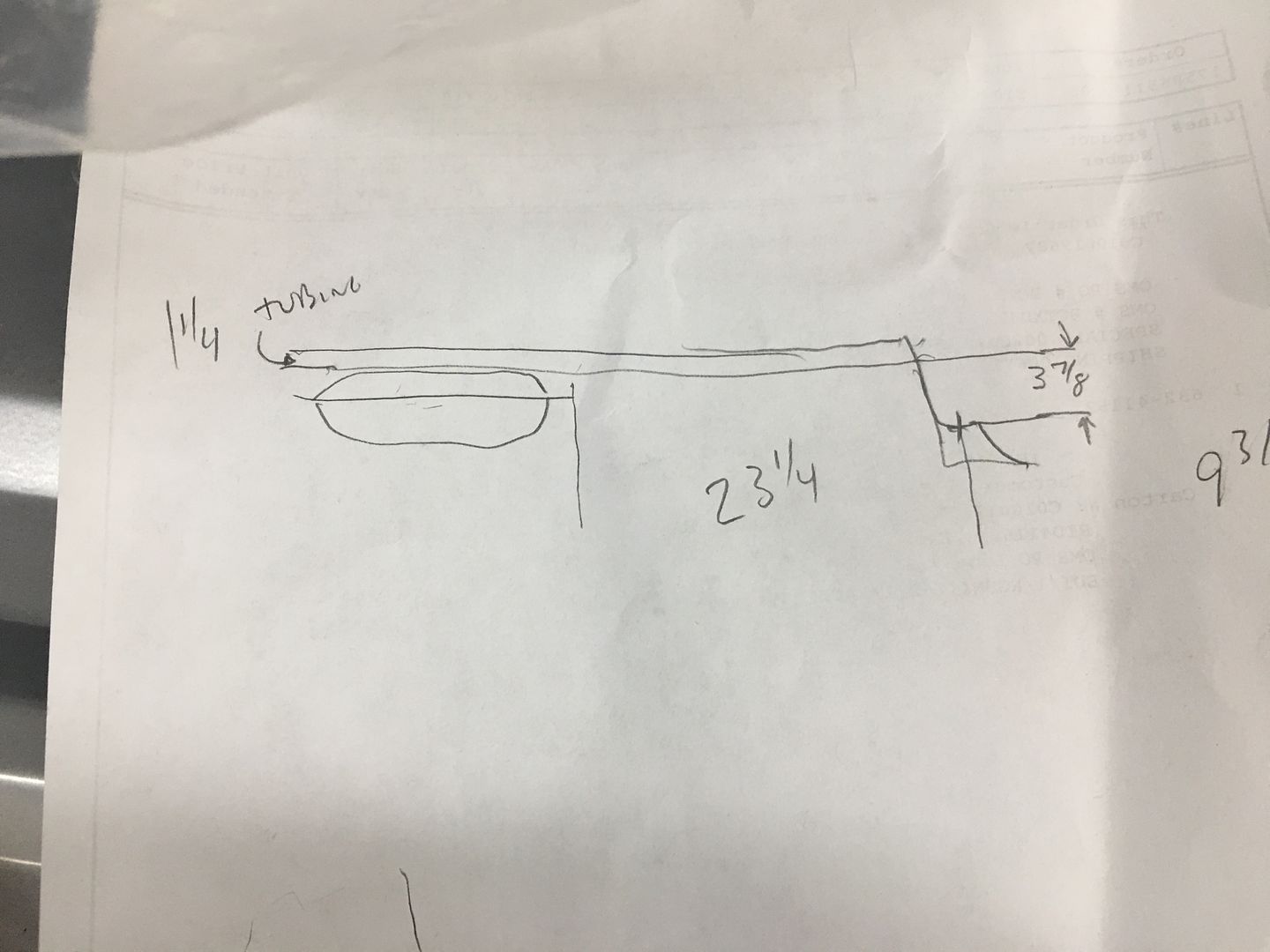

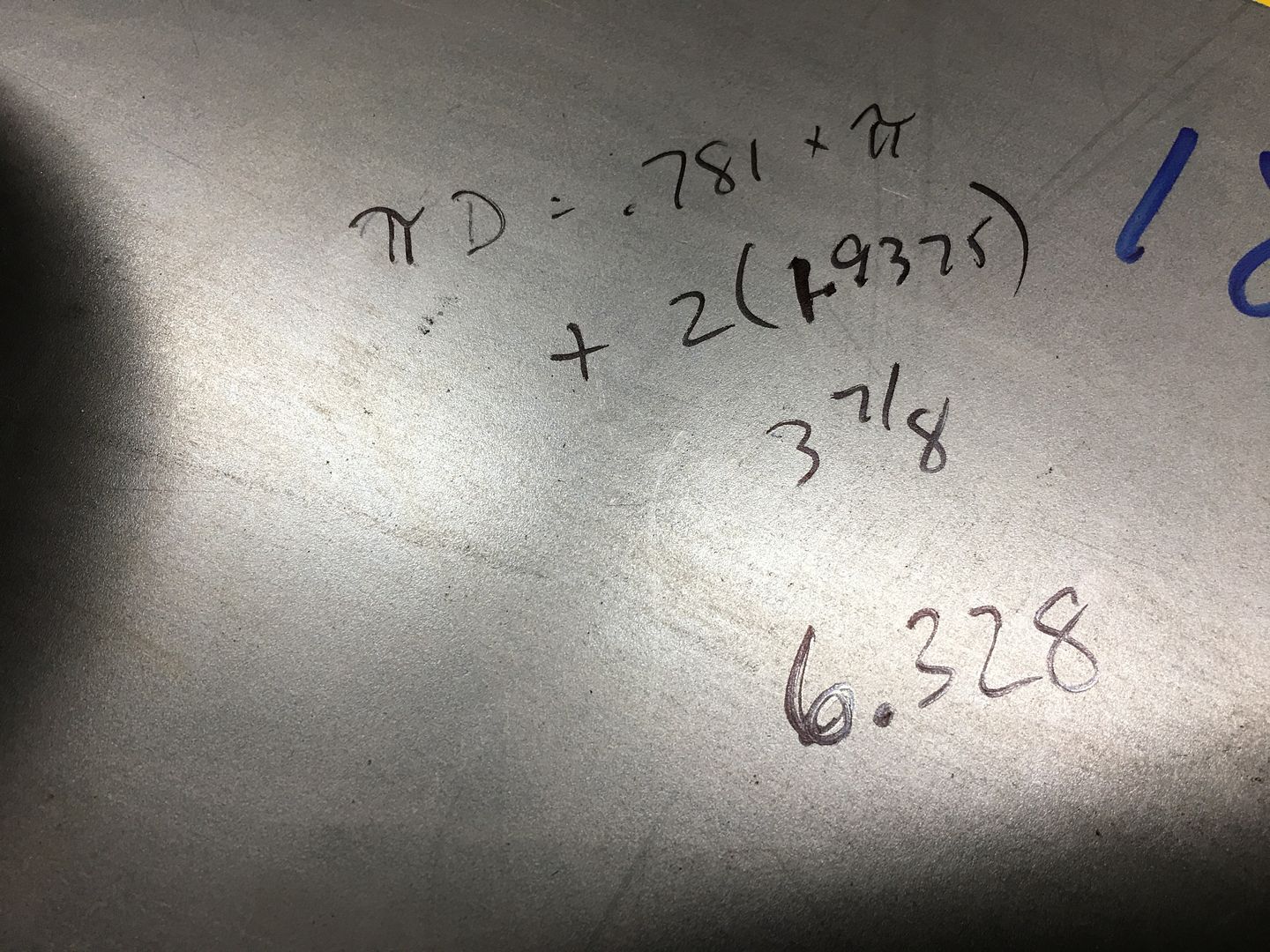

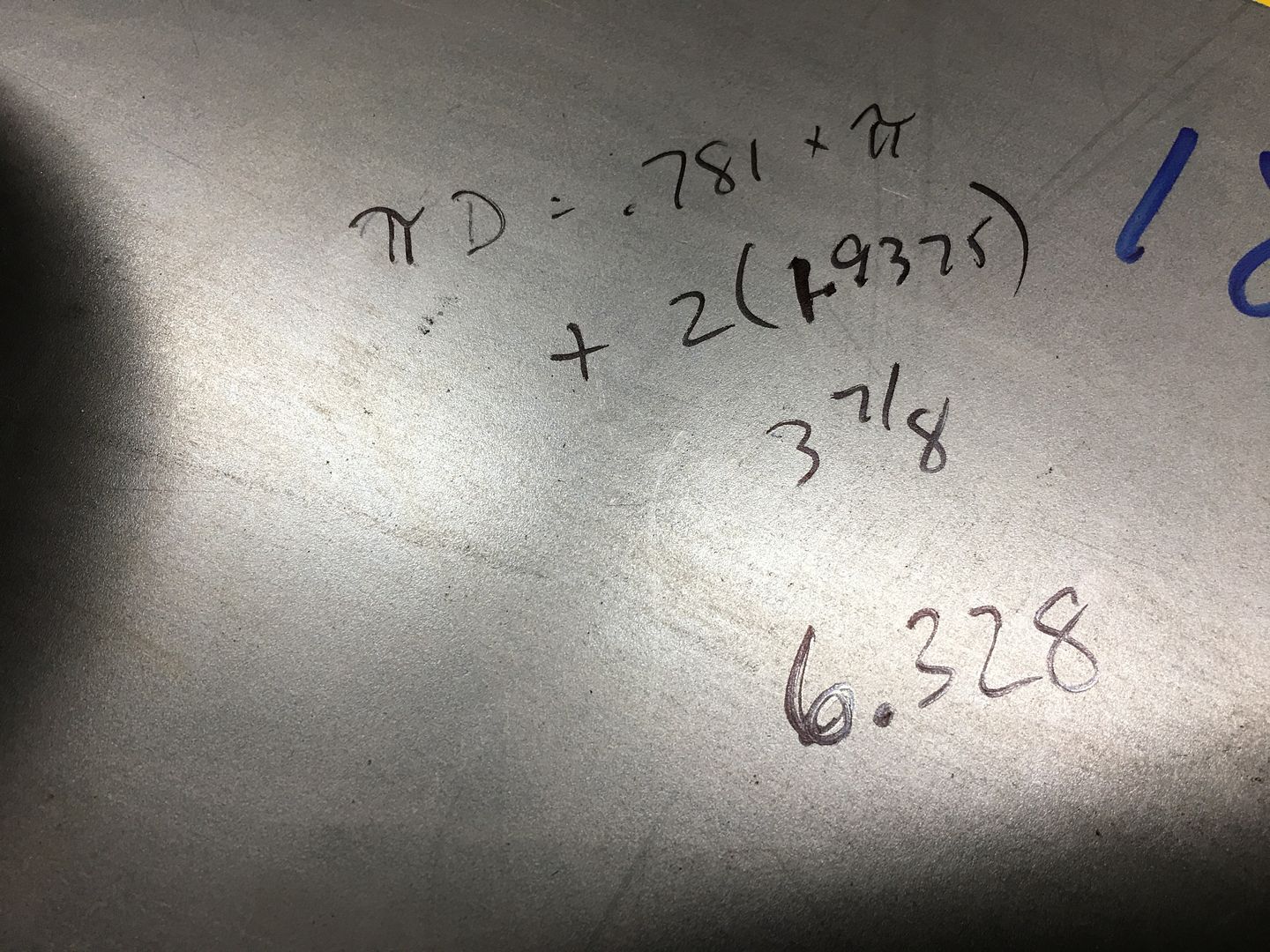

Some measurements and geometry from high school should get us the correct size from the onset...

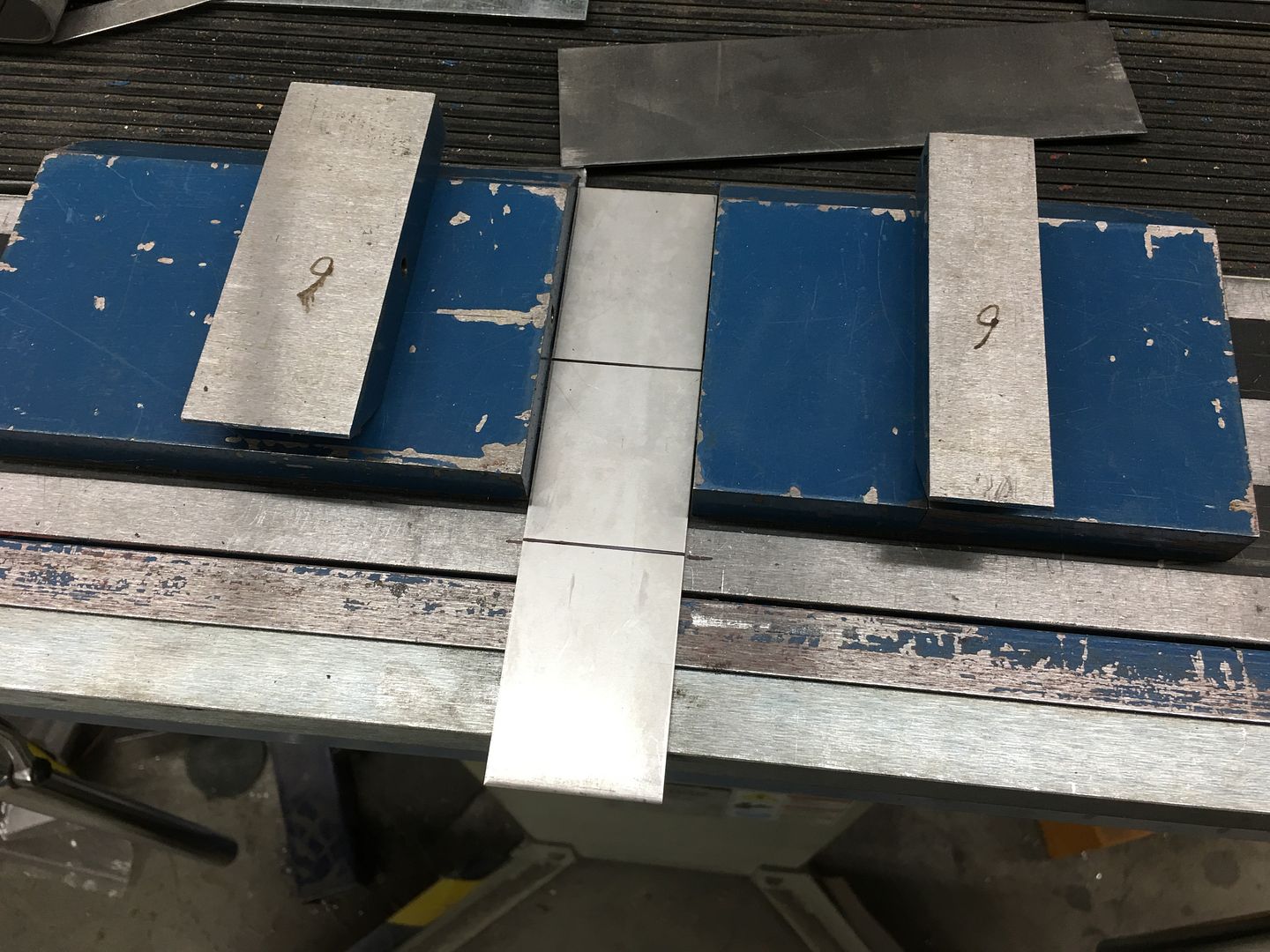

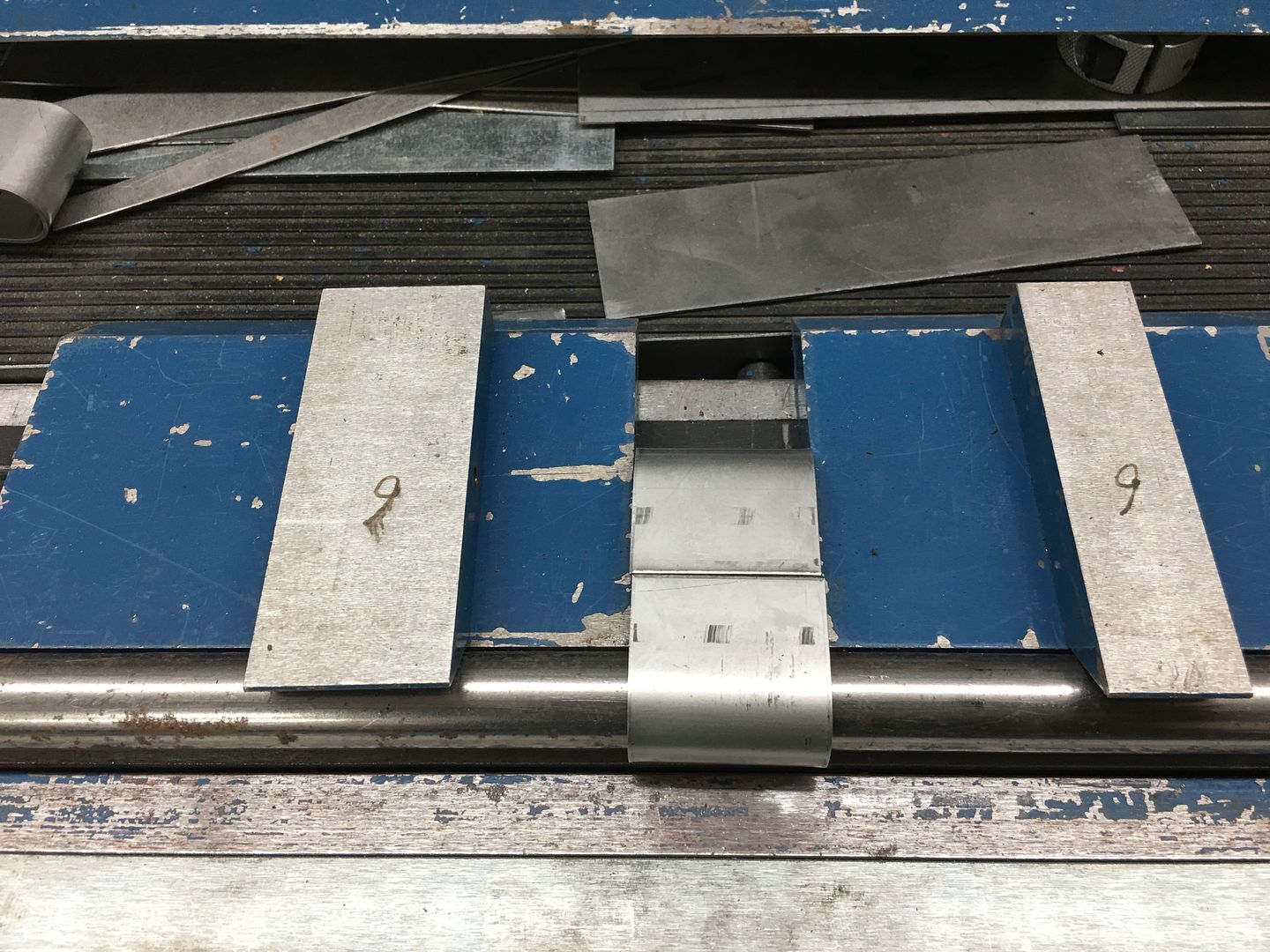

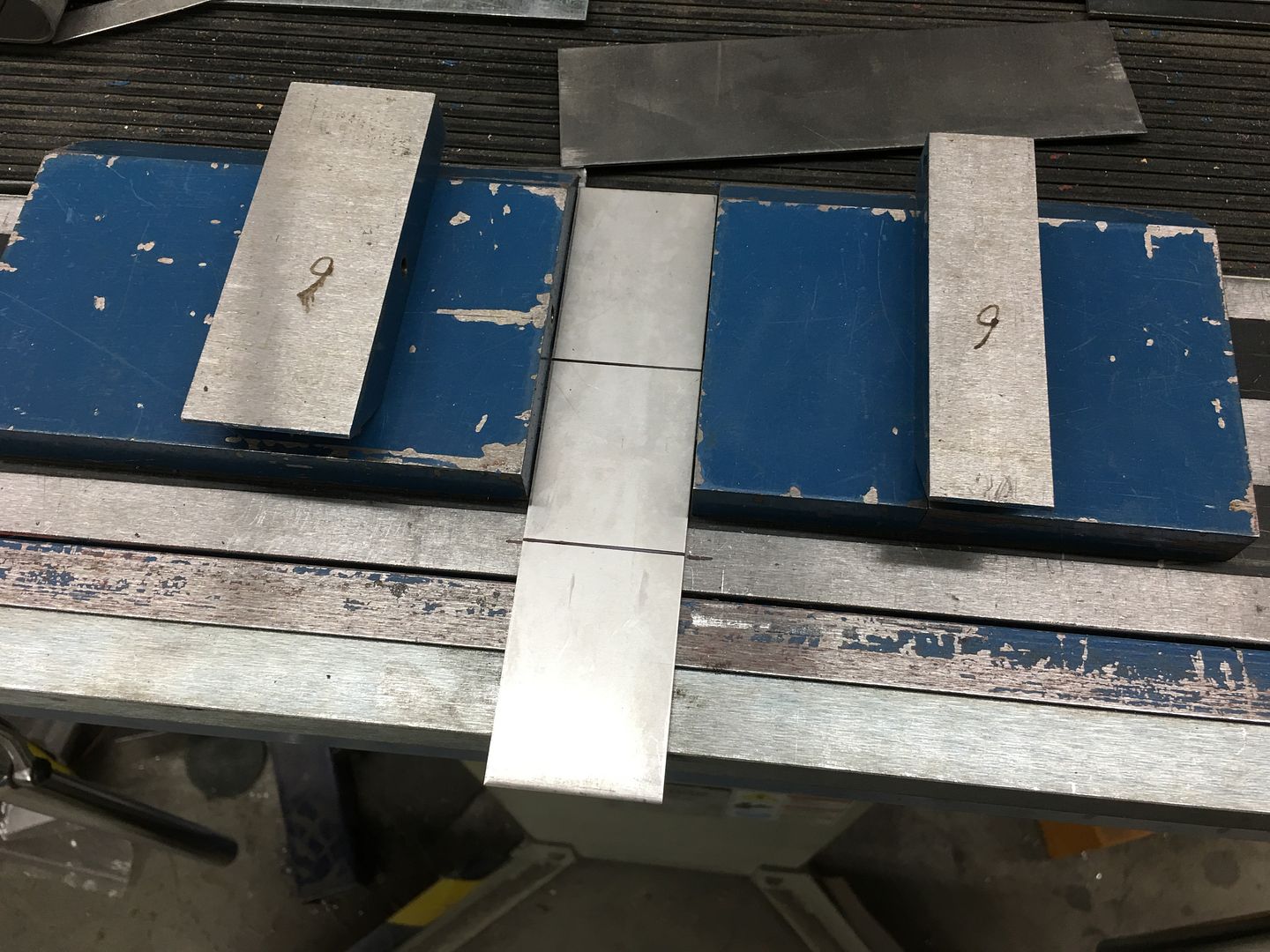

Using the mag brake and a 3/4 tube to bend our radius...

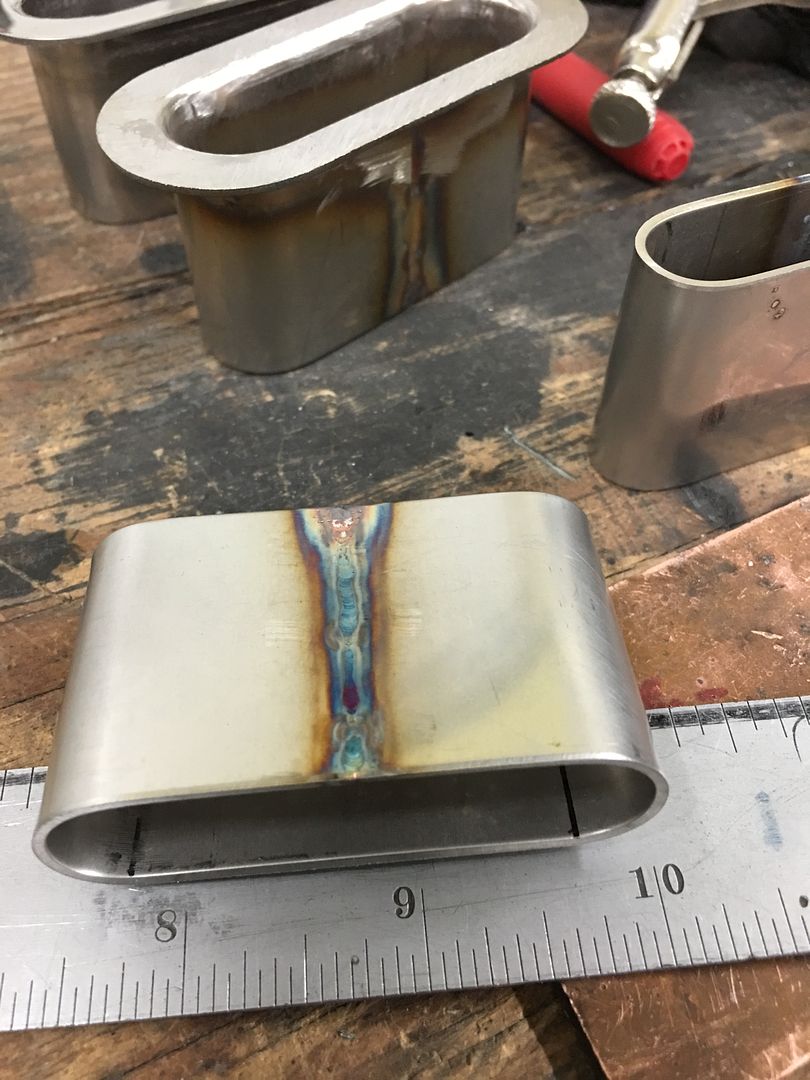

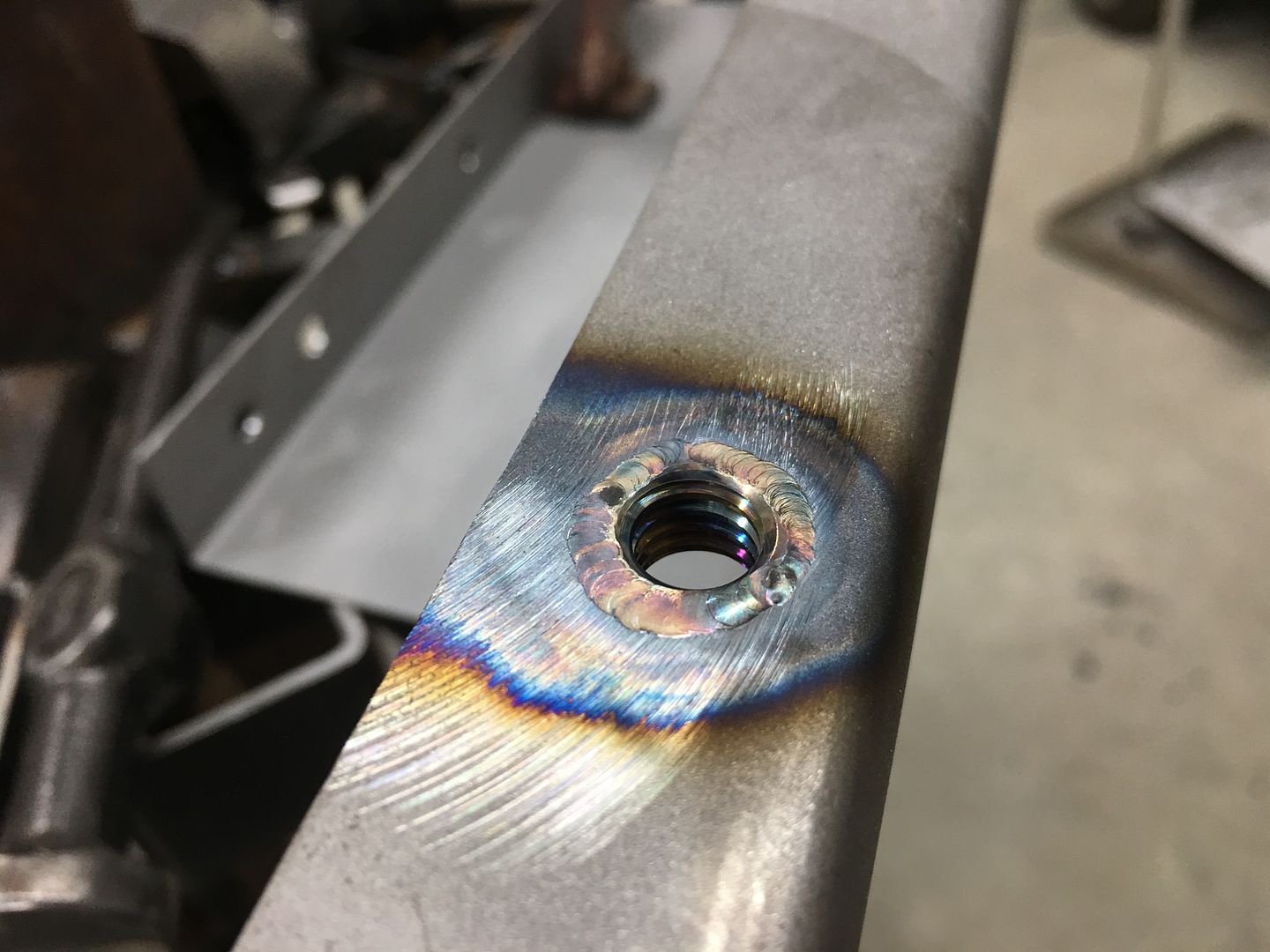

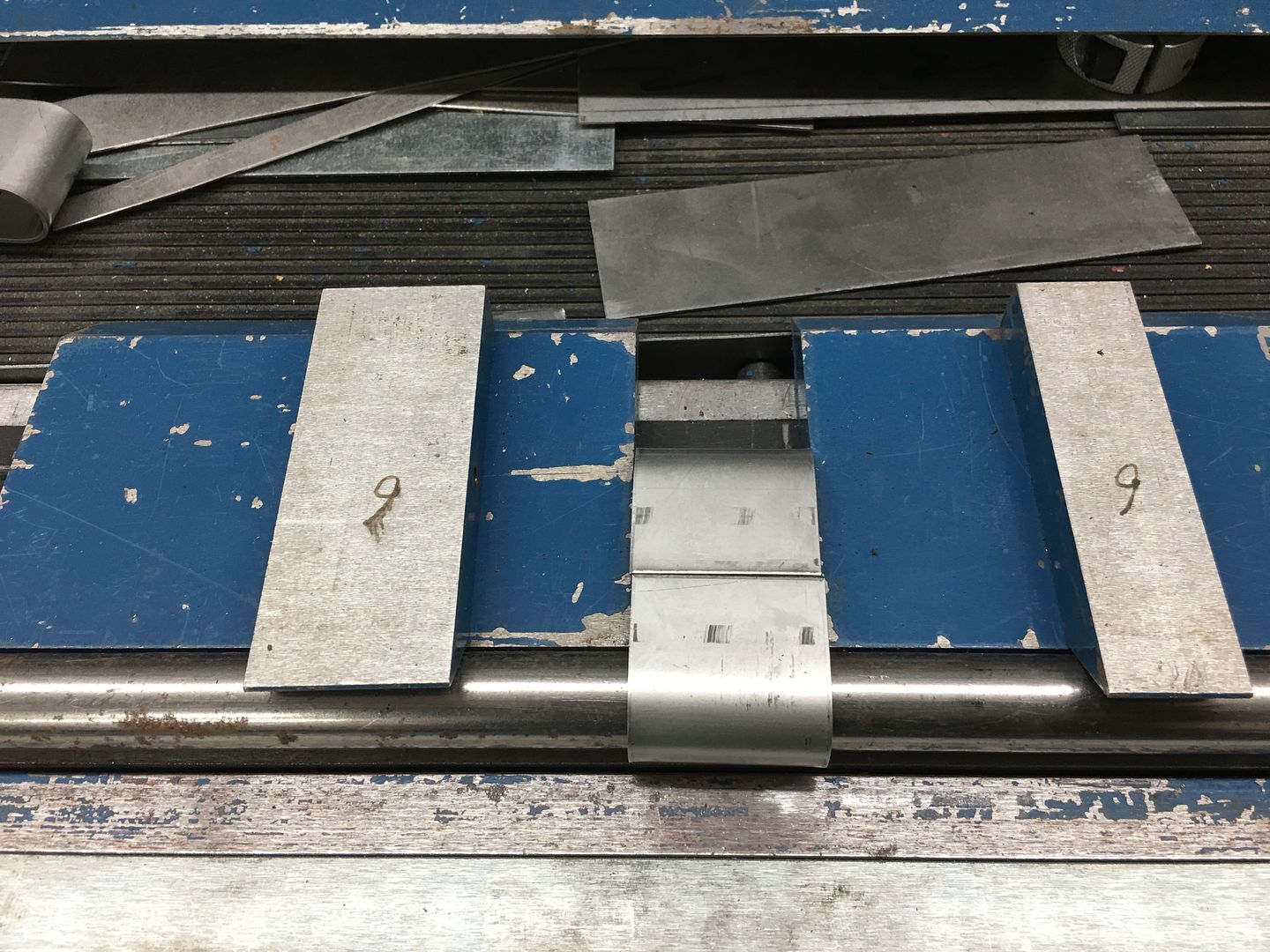

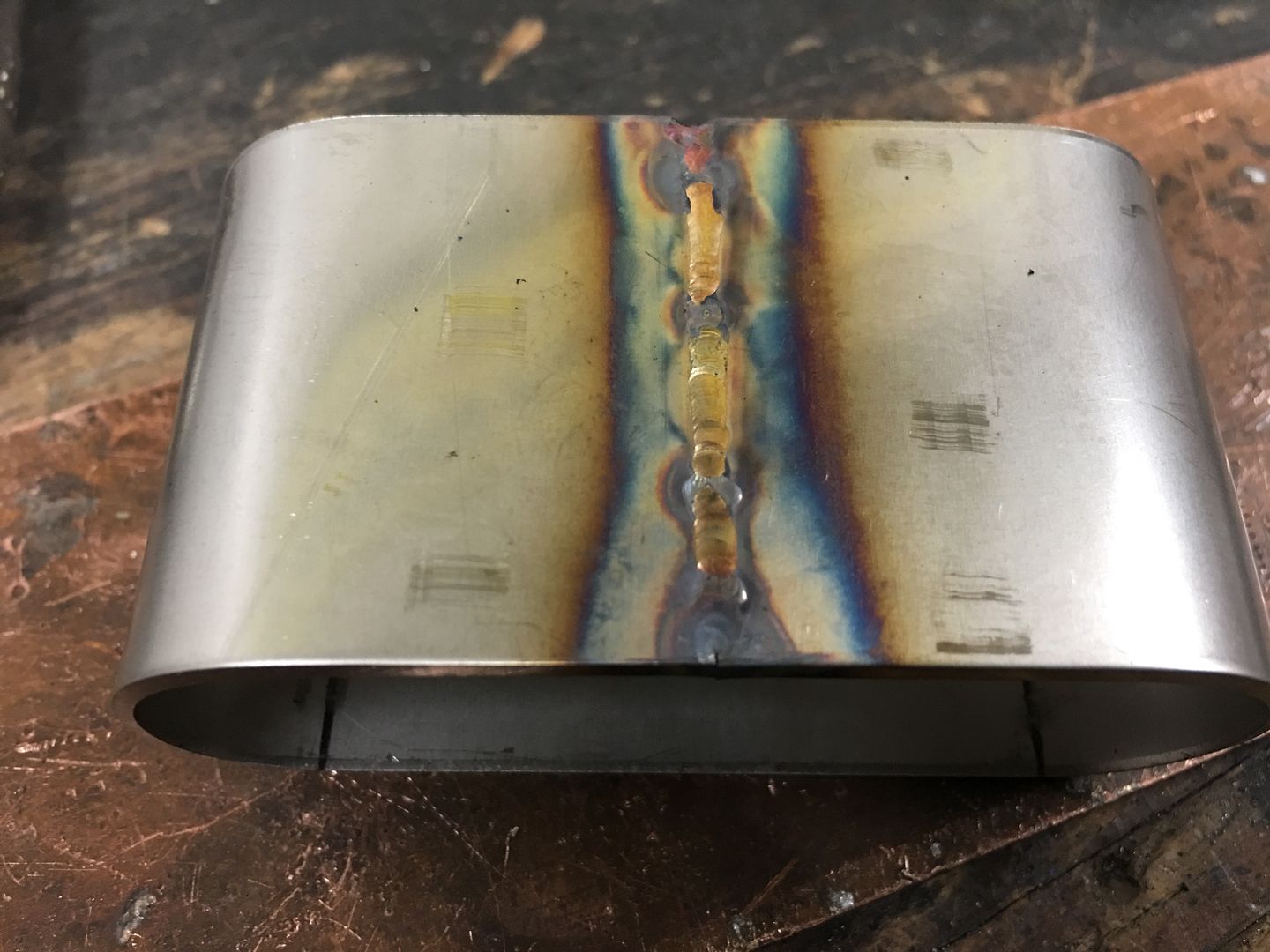

Tacked together using the TIG

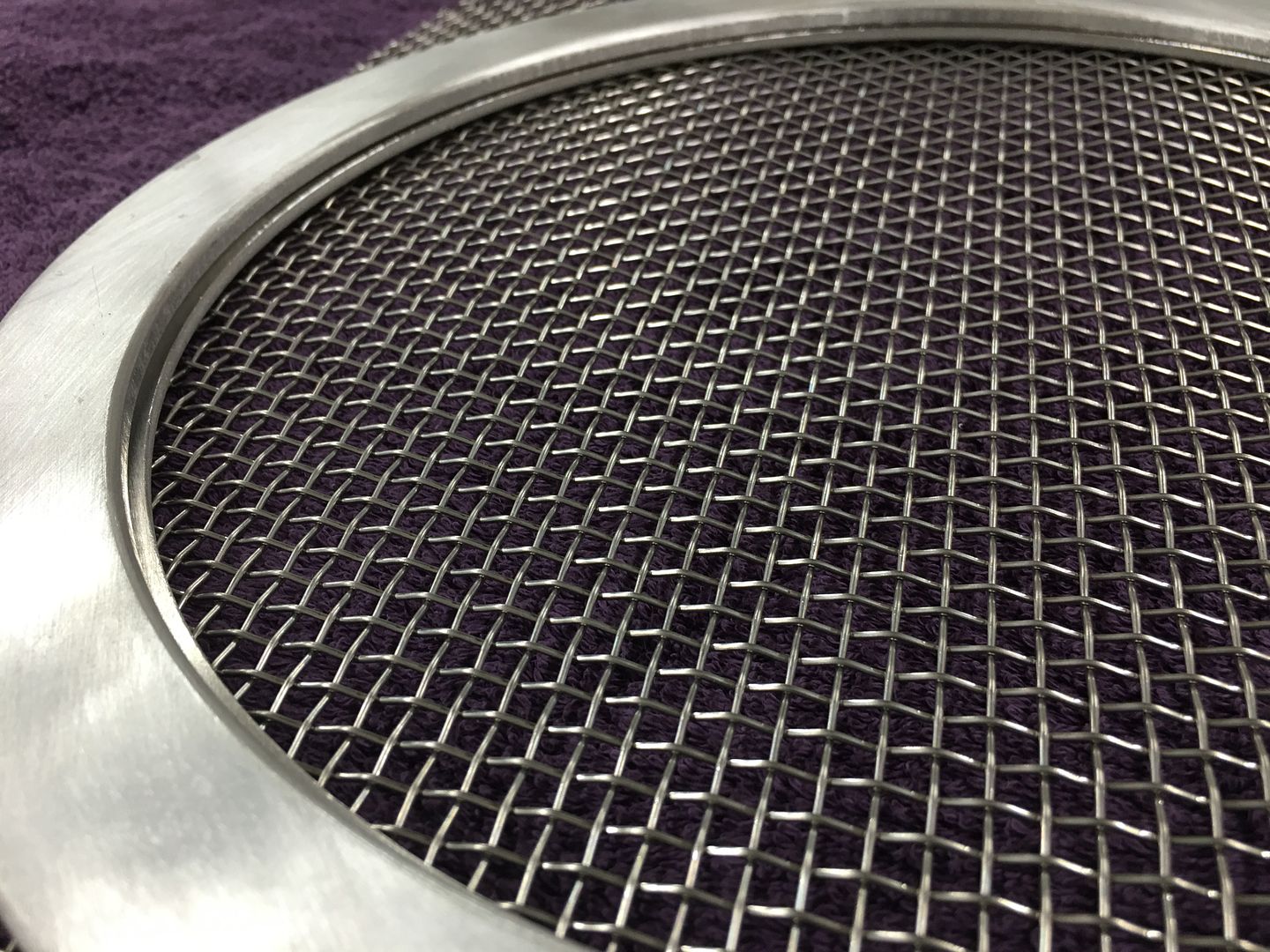

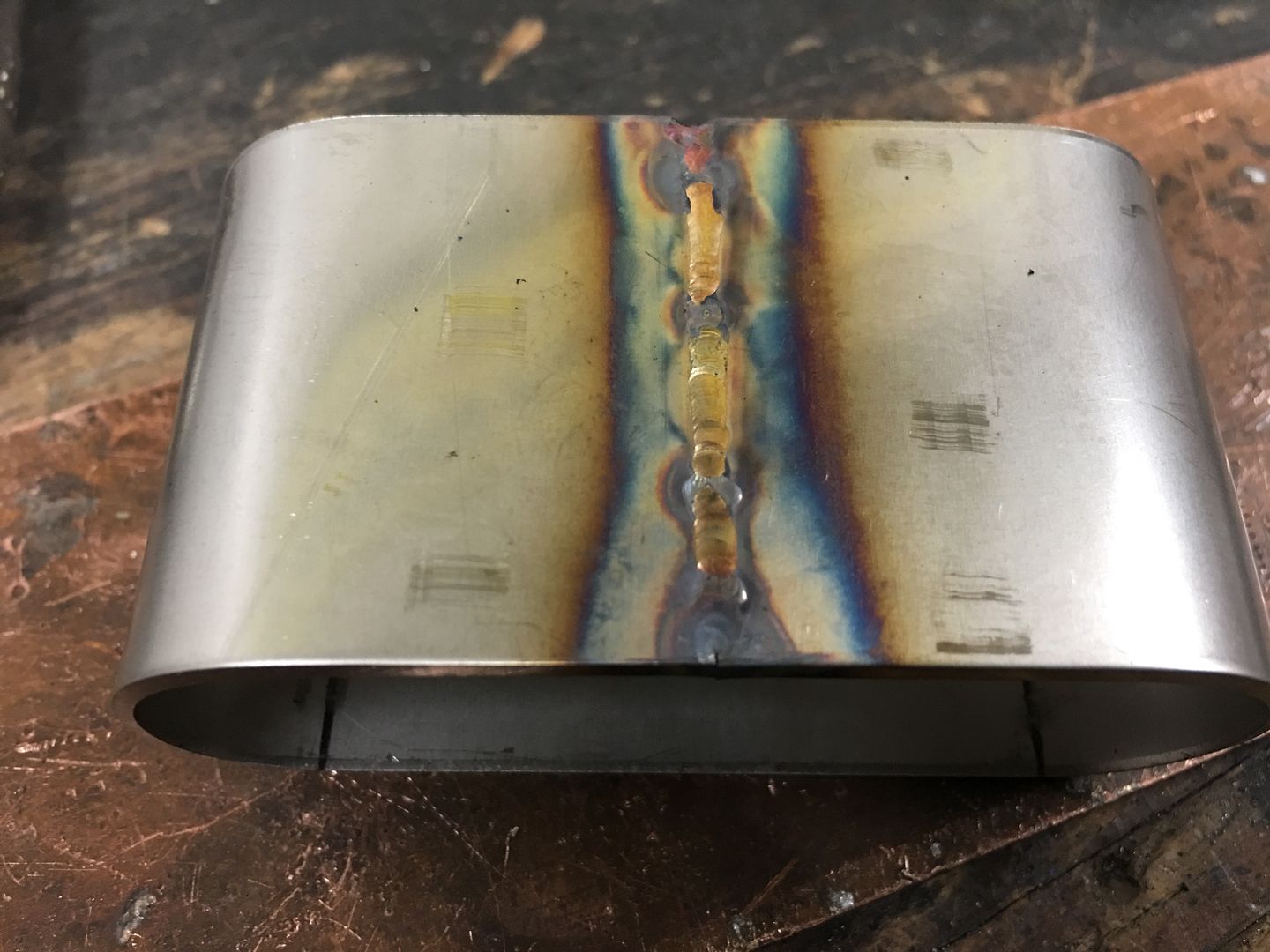

Got running late and missed some pictures, but here's the part welded up and polished..

.

Picked up the console from the powder coater, the outside was done in satin black and will be covered in upholstery, the inside parts were done in wrinkle finish, this will be their "covering"

Tonight we worked on some stainless for our seat belt escutcheons..

Some measurements and geometry from high school should get us the correct size from the onset...

Using the mag brake and a 3/4 tube to bend our radius...

Tacked together using the TIG

Got running late and missed some pictures, but here's the part welded up and polished..

.