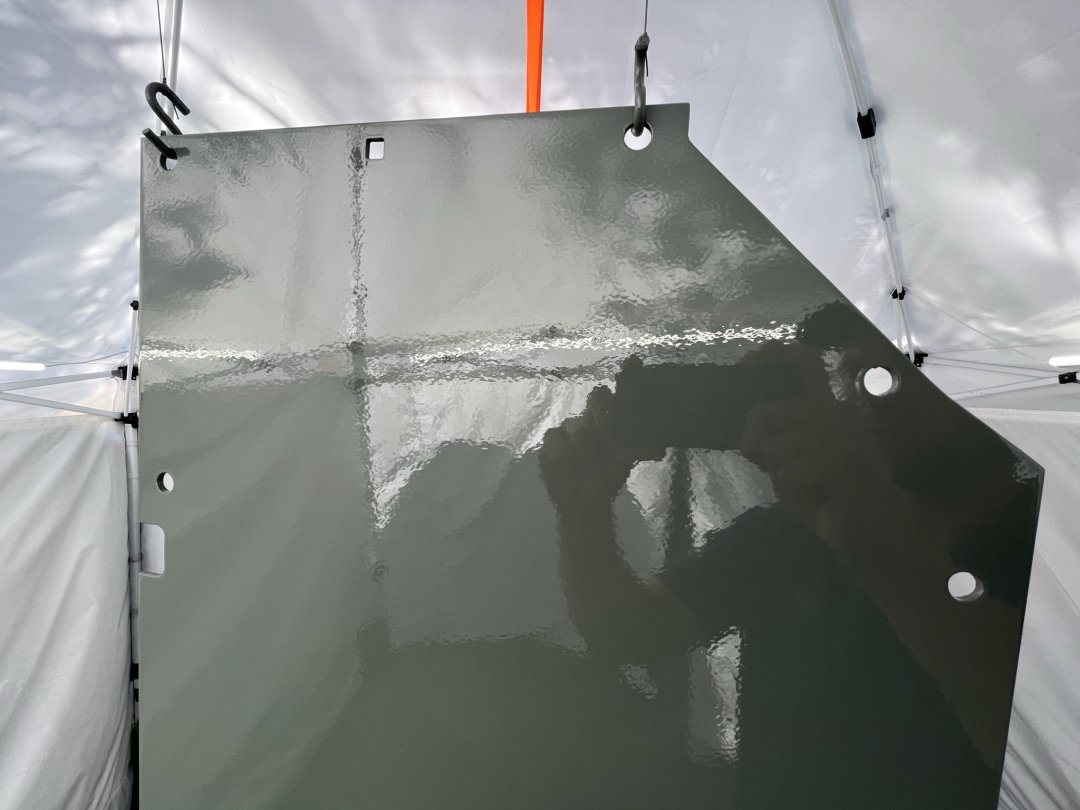

I'm just a novice painting in a tent outside, trying to imitate you guys who actually know what you're doing. Did a few floor panels as test panels in Delfleet solid single stage. 1/8 aluminum sheet, cleaned, DA 120, cleaned, 2 coat epoxy, wet sand 600, 1 more coat epoxy as a sealer (just to try it), 2 coats SS next day. Astro EuroPro EVO-T 1.4 LVLP gun, painted vertically, air temp 70F, panel temp 80F (concrete held heat overnight). Pics are 6 hours after curing at ~85F. Any thoughts on the result? I wasn't sure how much orange peel to expect. Maybe cut with 1500 and buff?

Last edited: