MP&C

Member

Progress through today, TIG welding up the hinges onto the new hoods..

Some SPI epoxy is mixed and brushed on, allowing it to seep between the welded parts and seal things up..

As the dominoes continued falling, the hood sides did not fit either. It was our initial plan to cut off the hinge from the top, wire edge from the bottom, and add a new center section, all parts cut to fit properly and welded back together. When we stripped paint off the lower wire edged part, we saw a bit too much pitting, rust, etc. that we opted to change to a full new lower section under the hinge. Nothing to wire edging 16 gauge, right?

So we whipped up a set of dies to add the joggle needed for the external wiring, using 3/16 solid rod for the wiring..

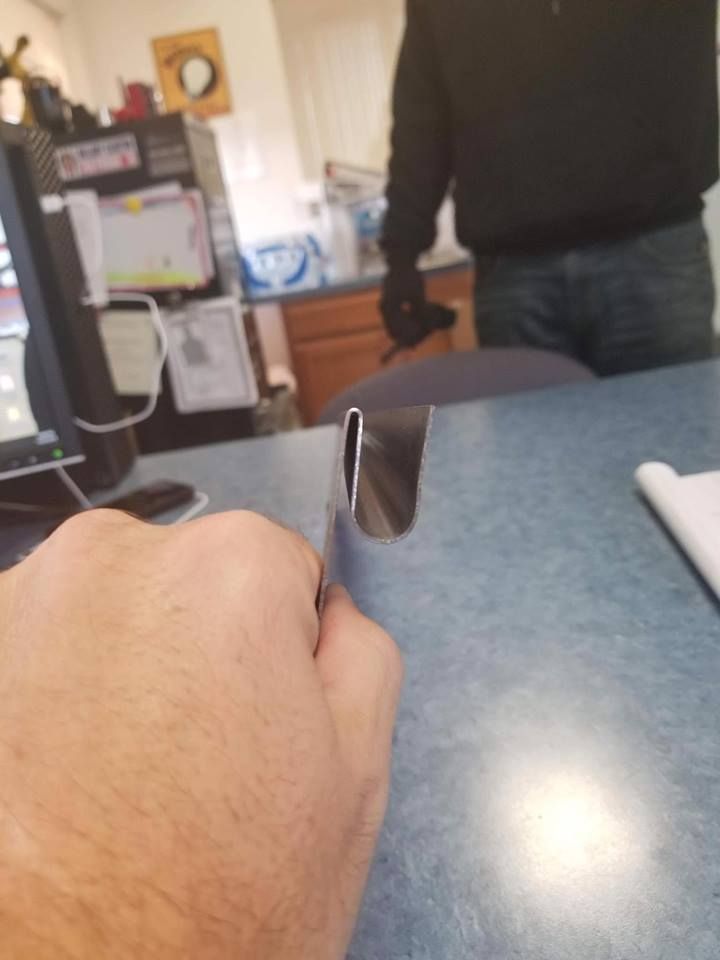

Practice sample:

With that complete, we tipped the lower edge to run through the joggle die..

The wiring and inside of the joggle were both degreased, scuffed, and SPI epoxy added prior to folding the remainder..

Vise grips modified so they wouldn't slip off the wiring..

Wiring locked in place with some hammer action...

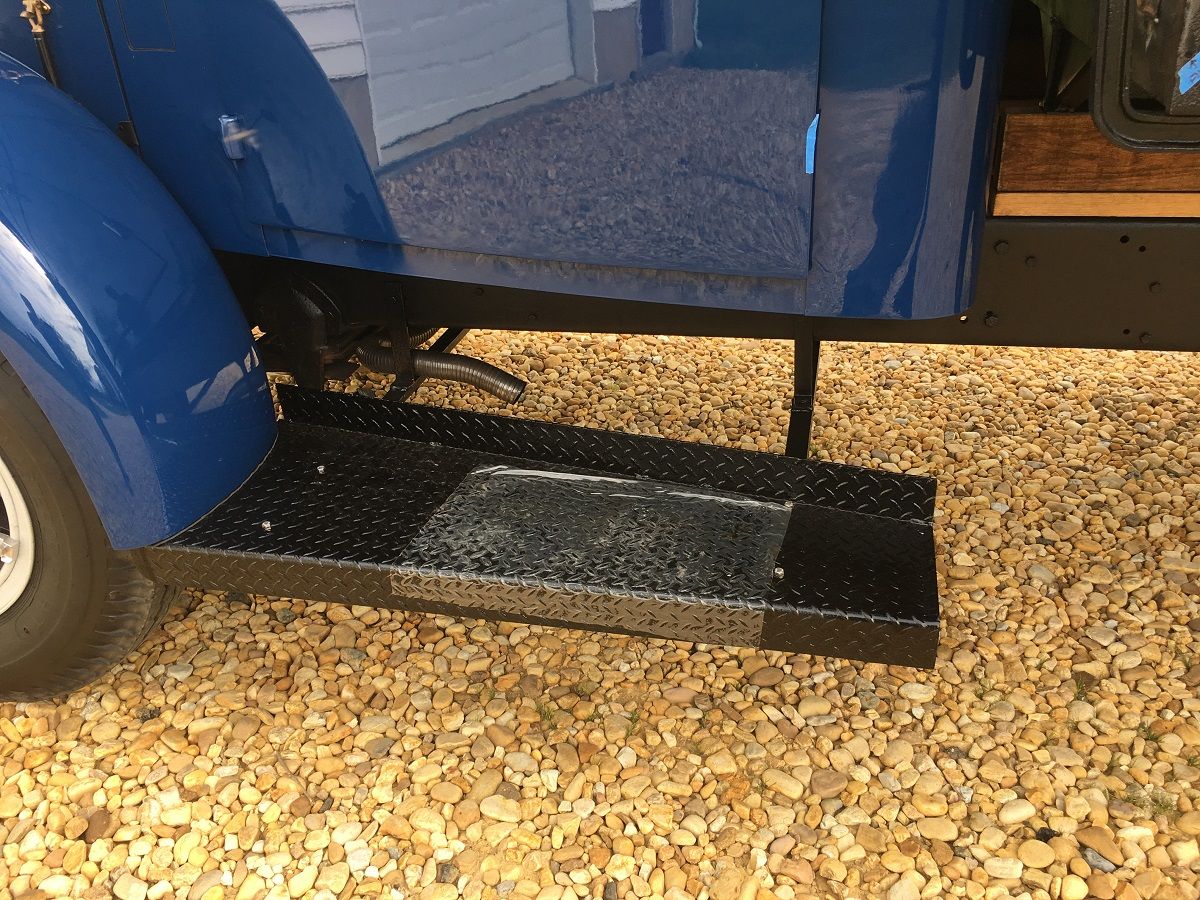

Hood side is tacked to the hinge, mocked to the hood, and trimmed for gaps

It's not done, but that's all for today, we're packing it up for the car show in Leonardtown tomorrow.

.

Some SPI epoxy is mixed and brushed on, allowing it to seep between the welded parts and seal things up..

As the dominoes continued falling, the hood sides did not fit either. It was our initial plan to cut off the hinge from the top, wire edge from the bottom, and add a new center section, all parts cut to fit properly and welded back together. When we stripped paint off the lower wire edged part, we saw a bit too much pitting, rust, etc. that we opted to change to a full new lower section under the hinge. Nothing to wire edging 16 gauge, right?

So we whipped up a set of dies to add the joggle needed for the external wiring, using 3/16 solid rod for the wiring..

Practice sample:

With that complete, we tipped the lower edge to run through the joggle die..

The wiring and inside of the joggle were both degreased, scuffed, and SPI epoxy added prior to folding the remainder..

Vise grips modified so they wouldn't slip off the wiring..

Wiring locked in place with some hammer action...

Hood side is tacked to the hinge, mocked to the hood, and trimmed for gaps

It's not done, but that's all for today, we're packing it up for the car show in Leonardtown tomorrow.

.