Thanks, yes, I can sit and watch her videos all day.

More progress on the wagon, (the green one) working on the parts so we can assemble and install the vent windows. For our glass installation, we did things twice as the 1/16 rubber did not give a snug enough fit. So here is our second round using 3/32 thick rubber. One inch wide strips were cut out of the sheet and lubricated with an Ivory/water mix.

The rubber was wrapped around the glass and it was pressed down inside the frame by hand. Then a "slight" squeeze of the frame to ensure it wasn't sprung open from the installation process.

These got moved to the attic for a good heat baking (drying the soapy solution) and we'll trim the rubber flush with the chrome vent frame in a couple of days.

Next, onto prepping the stainless trim for the vent windows for buffing, refining the scratches. Detail work like this is more difficult with parts flopping around in your hand, so some MDF was found the correct size (width) to hold the wide portion of the trim, and another piece of MDF was shaved to fit the narrow piece of trim. We should have these done this weekend.

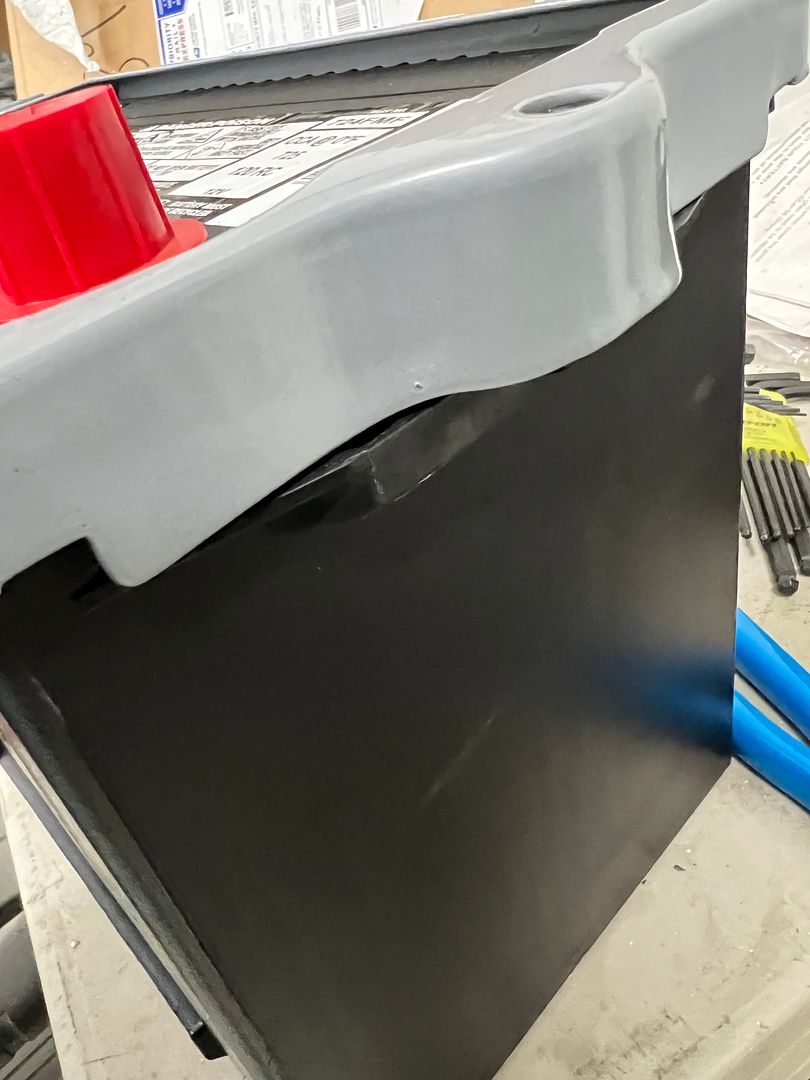

Next, we picked up our battery, but the lifting handle bosses on the ends of the battery interfered with our OEM hold down.

Not to be dissuaded, the belt file made short work of a shave.

Luckily the mount hides our sanding marks. Much better down where it belongs...

Like it's made to go there...