W

wisch79

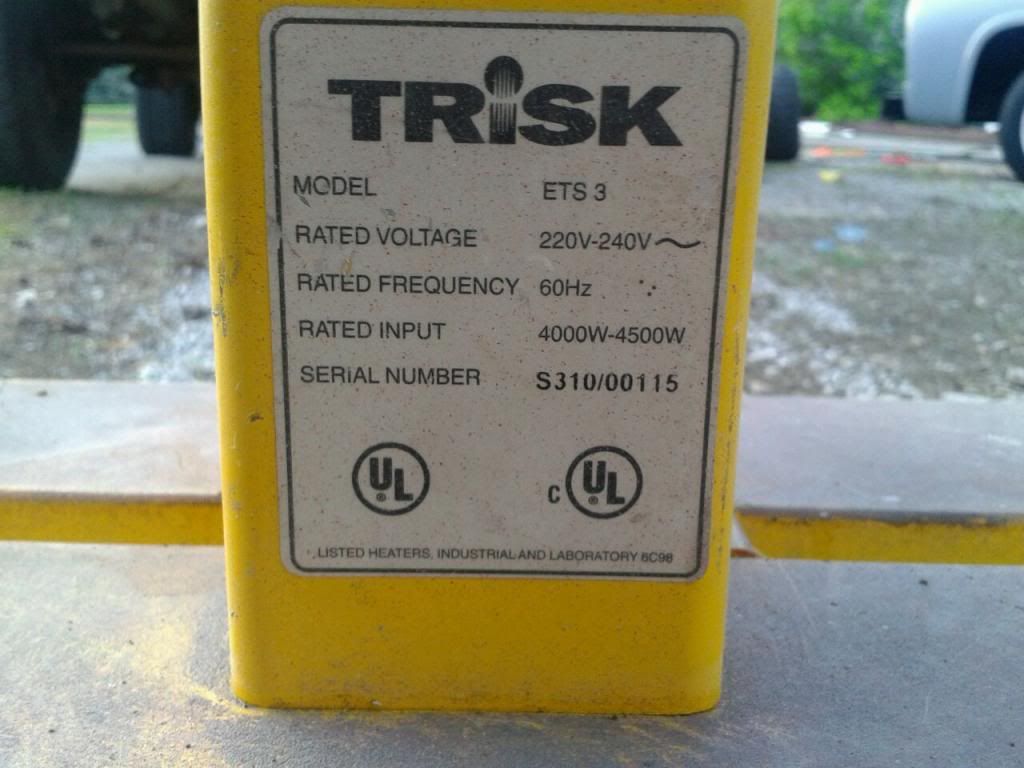

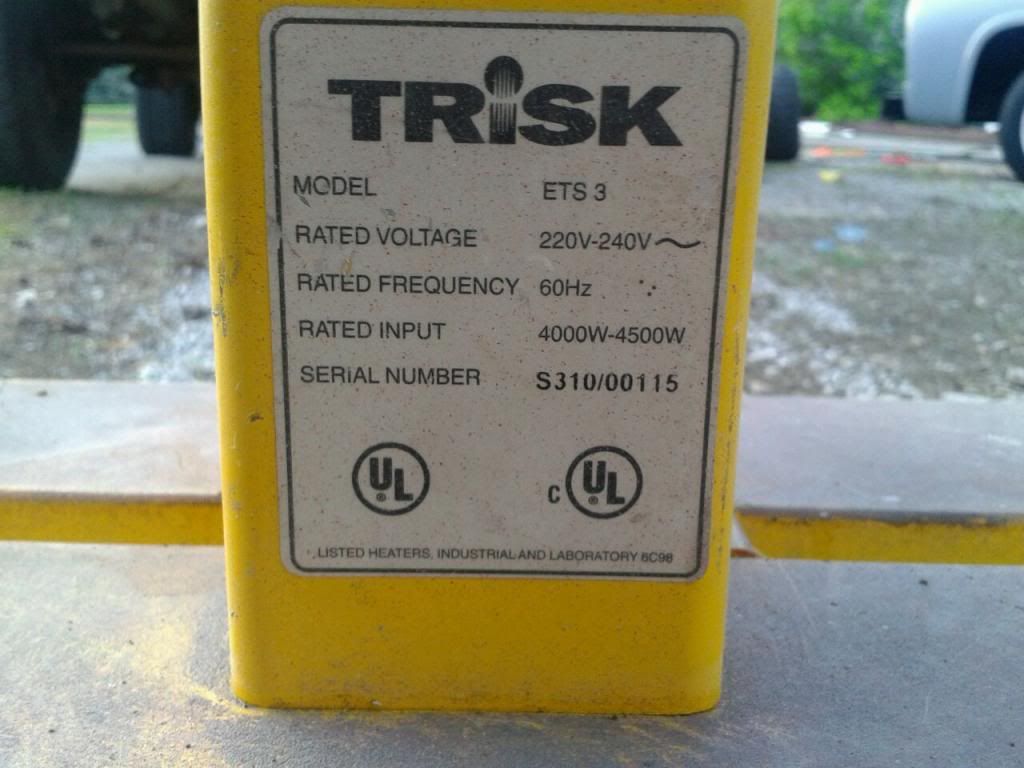

A buddy called me today and said he saw this paint curing lamp at a yard sale today and wondered if I was interested. He said the owner told him he bought it from a body shop that closed down and said it worked. However, he ran over the cord with a forklift and cut a wire, so he cut it off but never got around to putting a new one back on. It has 3 heads and is a Trisk ETS 3 220V. I told him I would gamble on it and buy it if he had the money. He dropped it off earlier and this is what it is.

I have never used anything other than the Infratech SRU 1615 which just has an on off sitch. With it, I would just turn it on for a while and then turn it off. This thing has flash, bake, timers and a whole bunch of stuff I have no idea how to use. Has anyone ever used one of these before? Are they any good? Any tips?

I dont have much in it and have my fingers crossed it works. I hope to get it wired back up in a couple days, but thought I would try to get a little more info on it until then.

I have never used anything other than the Infratech SRU 1615 which just has an on off sitch. With it, I would just turn it on for a while and then turn it off. This thing has flash, bake, timers and a whole bunch of stuff I have no idea how to use. Has anyone ever used one of these before? Are they any good? Any tips?

I dont have much in it and have my fingers crossed it works. I hope to get it wired back up in a couple days, but thought I would try to get a little more info on it until then.