R

Rustbuster77

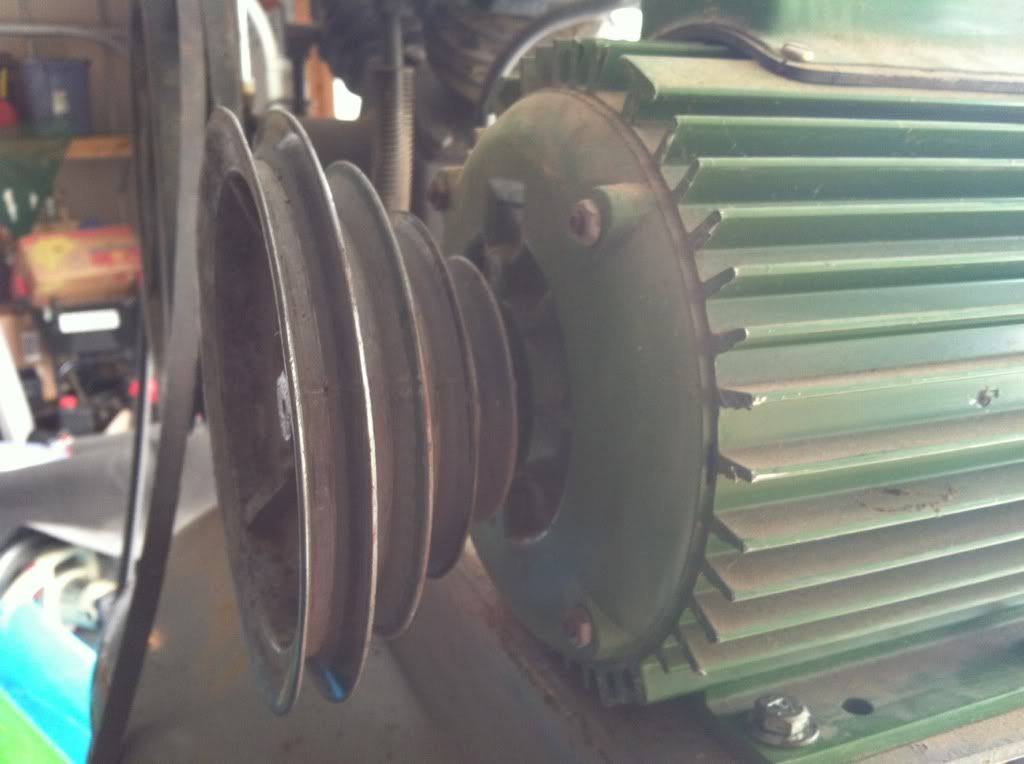

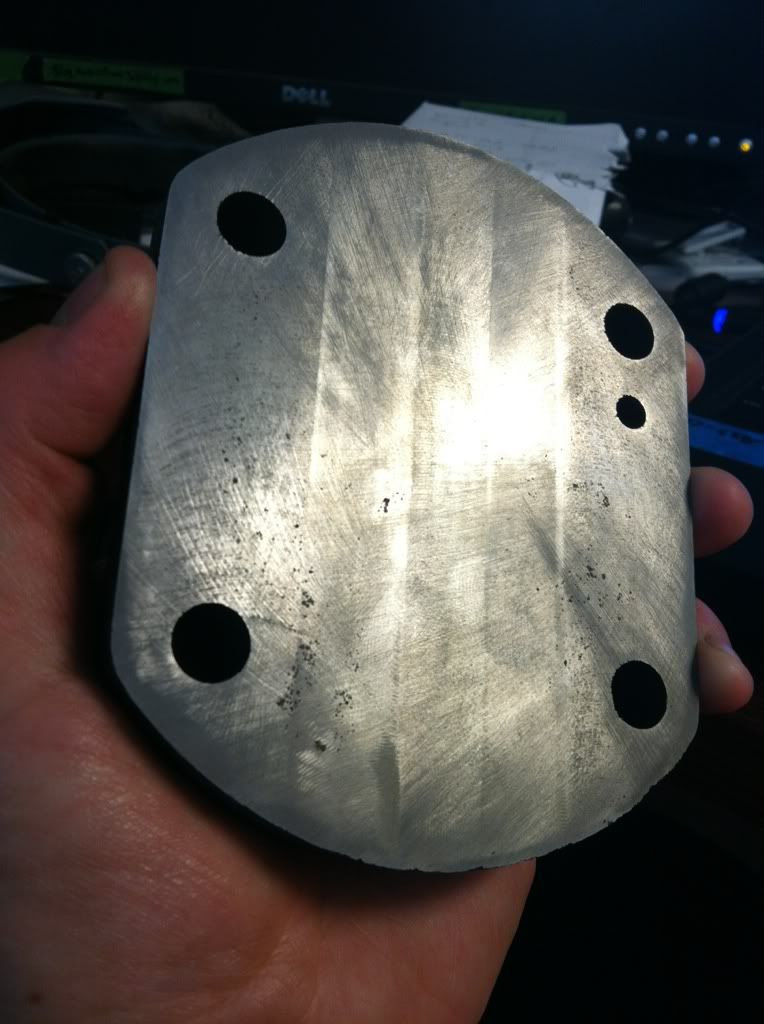

Recently got this beast and will be tearing into it this week to rebuild it. Found the low pressure side cylinder walls partially scored, eggshaped, rusty valve spacer plates, broken valve finger, undersized (1HP) motor, and a few other things. Just ordered a new valve and spacer plate kit for both sides and replacing rings on both sides, then will hone the cylinders.

Should help. It was taking nearly an hour to fill up the 60 gallon tank. I'm guessing the lower compression, broken valve finger certainly wasn't helping.

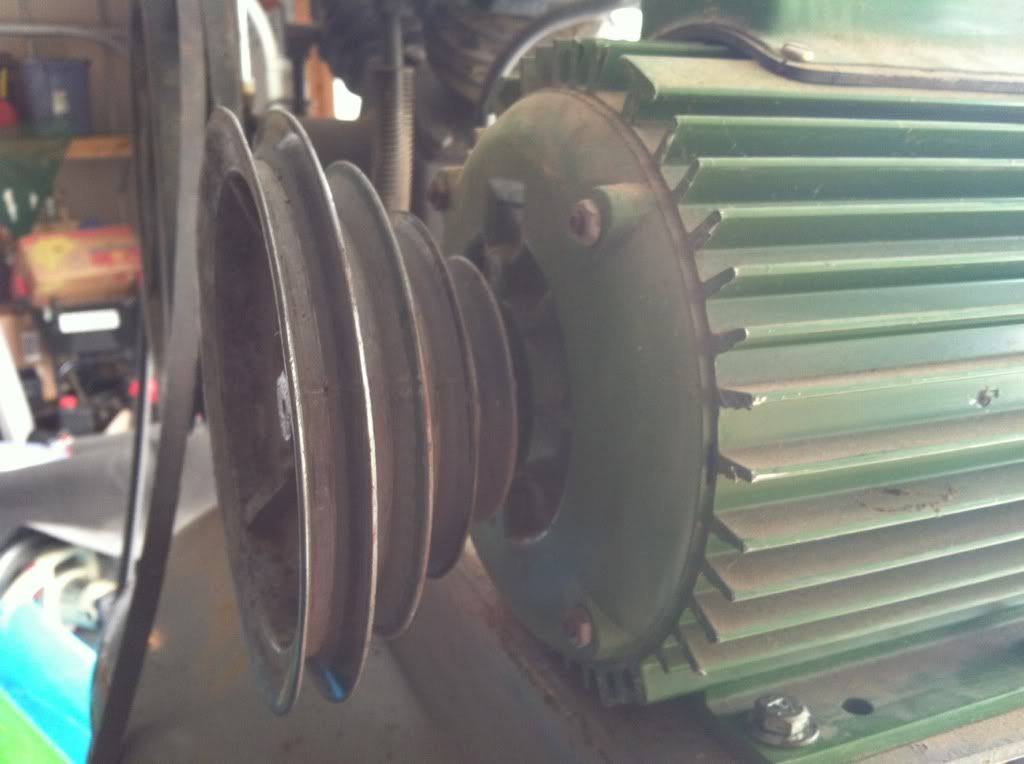

Here's a few pics and videos of the project thus far.

click on thumbnails to make larger.

Mark

Should help. It was taking nearly an hour to fill up the 60 gallon tank. I'm guessing the lower compression, broken valve finger certainly wasn't helping.

Here's a few pics and videos of the project thus far.

click on thumbnails to make larger.

Mark