You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Painting Bolt Heads

- Thread starter ffltstn

- Start date

MP&C

Member

On some of the bus repairs I’ve done which use screws to hold on various body parts, I’ve found excessive build on the Phillips head screws will lead to paint chips during the installation process. Here lately we use stainless hardware to minimize rust issues, media blast head of the screw using garnet, blow of any residue and spray two coats of catalyzed urethane. Have had better luck this way.

RenewAP

Promoted Users

Since you're sure to be touching up the hex area, I would give them 2 normal coats of epoxy, then as little color as possible from the sides, but full color coats straight down on the top. Then you only need to touch up the hex pads. Stay away from 12 point sockets, a good 6 point that is made to only contact the flats of the hex will give you the best chance of not chipping at all.

Lizer

Mad Scientist

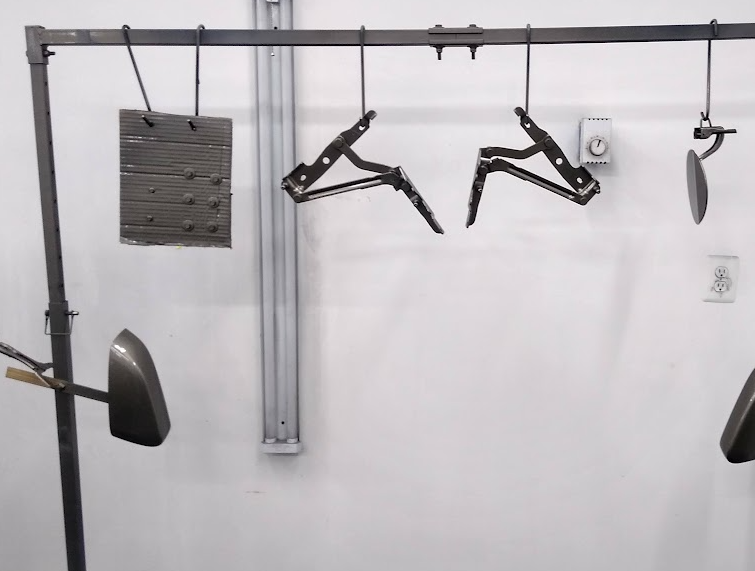

When I've done it I drilled a bunch of holes in a 2x4 block and set the threads in the holes and paint the heads. It kind of looks like a LEGO brick.

I don't like painting bolts anymore because there's always a little paint that gets cracked or scuffed off when tightening them down, and the reassembly becomes very cumbersome because you have to be so slow and careful when tightening down bolts.

I parkerize all my hardware now. It's durable, I think it looks clean and sharp and provides a nice contrast to painted surfaces.

I don't like painting bolts anymore because there's always a little paint that gets cracked or scuffed off when tightening them down, and the reassembly becomes very cumbersome because you have to be so slow and careful when tightening down bolts.

I parkerize all my hardware now. It's durable, I think it looks clean and sharp and provides a nice contrast to painted surfaces.

Chris_Hamilton

Trying to be the best me, I can be

If they have to be painted, and they have to be "perfect", and you have to do them off the car, often times you will need to mask off after assembly and re-shoot the bolts with a detail gun. One thing to try is using some Saran Wrap and placing that over the bolt to be tightened. It helps some. Not always but much better than using nothing. I think a key is to media blast, then epoxy one coat, then paint.

When i need to do bolts in body color, I typically just sand blast them and punch them through cardboard. Light coat of epoxy, and only put one coat of clear to avoid build up. I try to let them cure up for a little longer before installing them, but sometimes that's not always the case so there are small touchups needed with a brush.

Lots of good choices are given here, and whatever works for you.

I save small parts for something to do one weekend as well as put l

Plastic on the floor and run cloths line for rod ends pulleys etc., as I have a bucket of ospho, water, and epoxy.

For big parts, I have a fish line and hook to hang.

Dip in ospho, then water, dry, dip in epoxy, and hang.

Bolts I punch holes in box and hand dip, so threads are not painted and set in box holes.

Let's of good ways to choose what's best for you.

I save small parts for something to do one weekend as well as put l

Plastic on the floor and run cloths line for rod ends pulleys etc., as I have a bucket of ospho, water, and epoxy.

For big parts, I have a fish line and hook to hang.

Dip in ospho, then water, dry, dip in epoxy, and hang.

Bolts I punch holes in box and hand dip, so threads are not painted and set in box holes.

Let's of good ways to choose what's best for you.

Lizer

Mad Scientist

It should hold up indefinitely for as long as the part stays oiled and/or it is stored out of the elements.Lizer how long does that process seem to hold up?

The cab of the truck and frame are sitting in a 3-sided shed for the winter and treated bolts on the exterior side aren’t rusting. They’ve been out there 6 months now.

I’ve since modified the process by adding a short water rinse to rinse off excess acid and zinc which tend to dry to a white chalk if there is excess on the bolt. After the rinse, I dry them immediately with a heat gun and then proceed to the oil dip.

Last edited:

metalman

Oldtimer

I have done a lot of hardware with the Cerekote heat cure gun finish. That process is blast with 100 grit aluminum oxide, spray on the coating no more that 2 coats and bake in the oven. Because it is applied to a grit blasted surface and is a thin hard coating it works pretty good on the hardware. Of course the doesn't help if you want a particular color but the have quite a few colors available.

On a side note I have the materials to try parkerizing, have not done it yet, but I plan to use it on a pistol.

On a side note I have the materials to try parkerizing, have not done it yet, but I plan to use it on a pistol.