rustover

Member

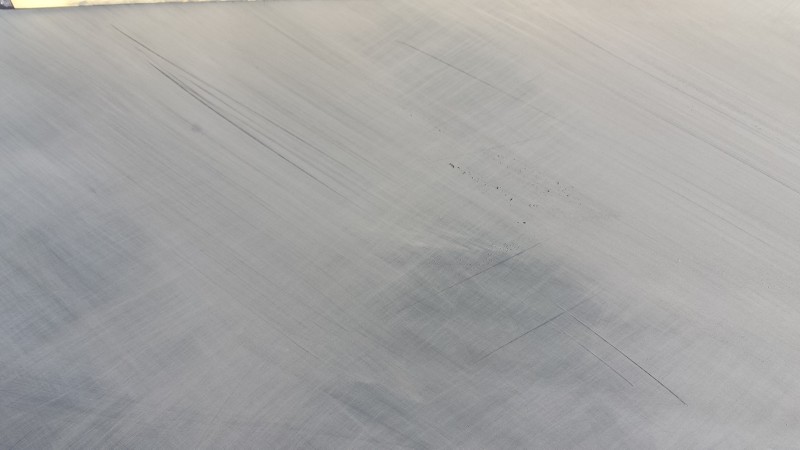

DATEC;n76350 said:You can use cheep sandable grey primer, I would use that for a guide coat before paint.

Excellent idea. I will pick some up this evening. Thanks.

DATEC;n76350 said:You can use cheep sandable grey primer, I would use that for a guide coat before paint.

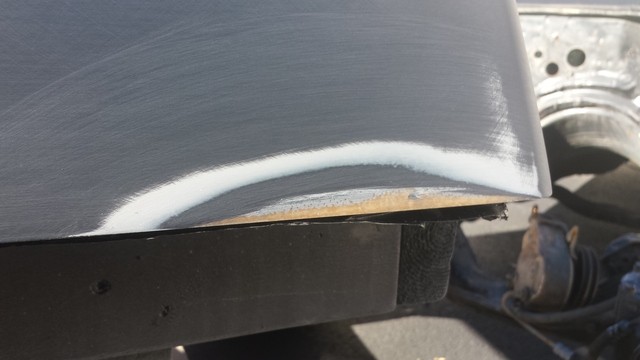

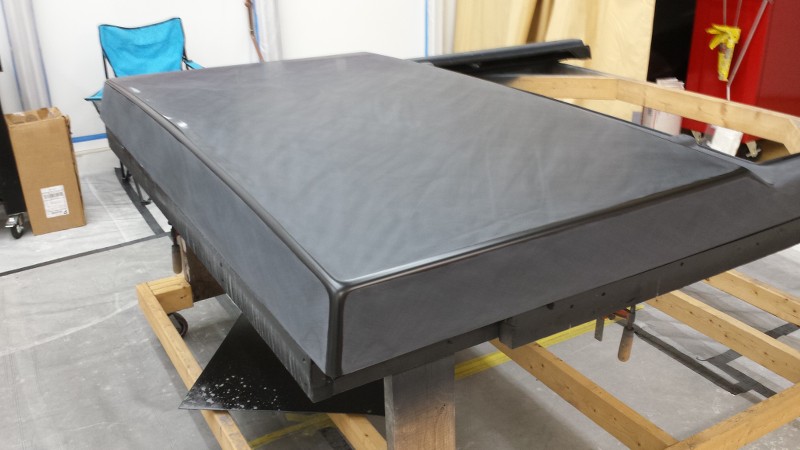

crashtech;n77397 said:As much as you have done to that, I would guess that it's ready to sand and shoot. Honestly I don't think those covers were ever intended to be perfect, and it's somewhat likely you will see some slight waviness return after a season on the hot sun anyway (sorry). Obviously none of us are there with you to say for sure, but it seems like you have already made it better than 99% of shops would ever do. The only question in my mind is if the brand of base you have will conceal the 320 marks. Most of the time, if you are sealing, 320 marks will be covered up, but it's not 100% for sure. Maybe the safest way is to put 2 more coats of epoxy on and this time don't touch it with coarse grits, just smooth it out with 600 and go. If you do this quickly enough, you don't even need sealer because the epoxy will still be "fresh" and the base will bite in and stick good.

chevman;n78155 said:I like the AFS, but you will never go wrong when using advice from Crash. When someone has in depth knowledge about the ins and outs and why things work or fail, then pay attention when they speak, you just might learn something. Thank you crash, and many others on this forum, for the outstanding information provided to us--just for the asking.