You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Automotive Rotisserie Question

- Thread starter '68 Coronet R/T

- Start date

Dean Jenkins

Promoted Users

Unnecessary IMO. When you get the CG right, one guy can rotate the car, almost with one hand, very easily.I noticed there are some out that have a worm drive w/hand crank for rotating. Pricey but might come in handy. I'm looking to see if a vendor has just the worm drive for sale. I've got a material list to build one just need to go get all of it.

John

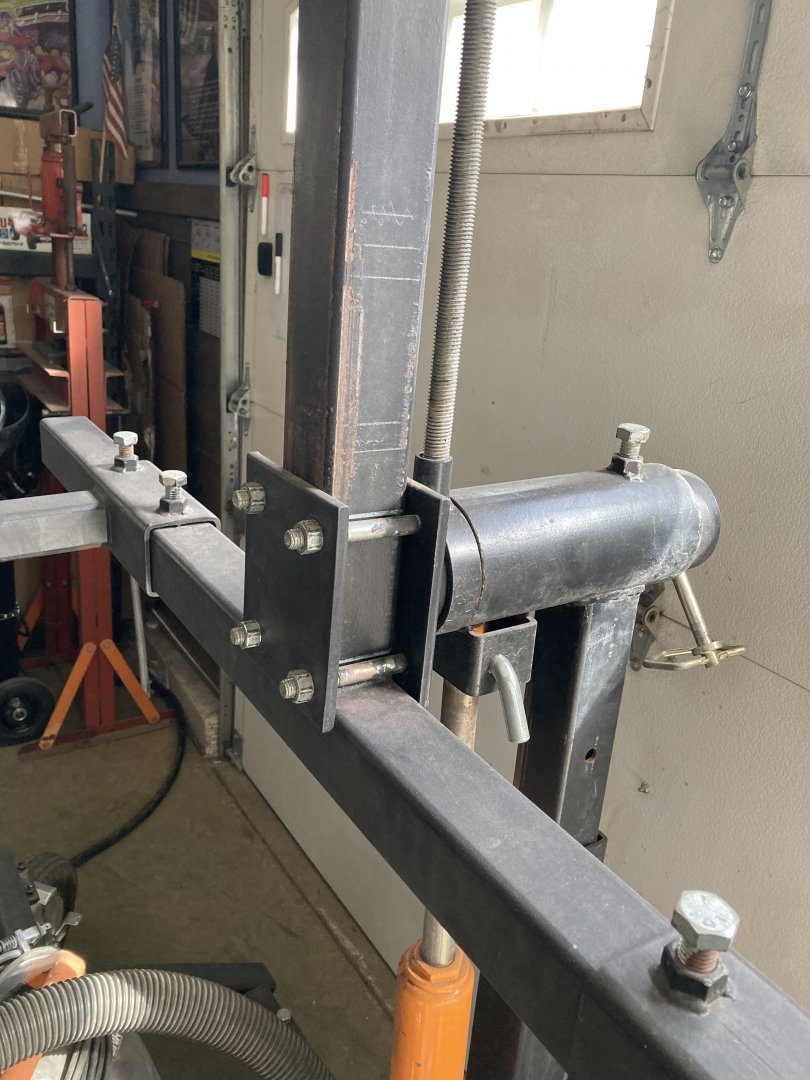

Not sure what is in your plans, but that pic doesn't include a locking ring/pin for rotation.

I found it very helpful on mine.

Also on that pic I don't see locking pin for the vertical adjustment - maybe it is on the backside - but I consider that mandatory. Don't want to leave the hydraulic jack holding it up.

You can see both on the Tuxedo model I bought

ct71rr

Promoted Users

Yes, you have to get your car balanced, not level. I have an Accessible Systems rotisserie and it looks similar to yours. When I first got it. I made the mistake of leveling the car - going by the rocker panels. The car needs to be balanced by finding its center of gravity. My front is higher than the back. You can check for balance by turning the car slightly and if it rocks back and forth, you’re out of balance. The car should not move (rock) when you turn it, no matter how slightly. You should be able to move the mounting ends up or down by those long screws attached to the upside down “T” pieces. My screws have a hex head on them for this. Once it’s properly balanced, you should be able to turn the car with ease and it should stay in whatever position you put it in without moving.

You can see in this pic my mounting arms (the upside down “T”) are almost all the way up:

Another view of the “T”:

Adjustment screw:

Rear, this “T” is slightly lower than the front:

Car is not level (at rockers):

You can see in this pic my mounting arms (the upside down “T”) are almost all the way up:

Another view of the “T”:

Adjustment screw:

Rear, this “T” is slightly lower than the front:

Car is not level (at rockers):

theastronaut

Promoted Users

I noticed there are some out that have a worm drive w/hand crank for rotating. Pricey but might come in handy. I'm looking to see if a vendor has just the worm drive for sale. I've got a material list to build one just need to go get all of it.

John

View attachment 24397

Those are nice, we have one with a gearbox and it makes it easy to rotate and it holds in place so you don't have to bother with the usual lock bolts at each end. Not sure about now, but Torin sold them through Northern Tool.

The pic I posted was to reference the worm gear only which is similar a right angle gearbox. This configuration makes near imposible to turn the output shaft on it's own. The only way they will turn without the input turning is if the main gear shears the teeth off or it shears the wood drift key.Unnecessary IMO. When you get the CG right, one guy can rotate the car, almost with one hand, very easily.

Not sure what is in your plans, but that pic doesn't include a locking ring/pin for rotation.

I found it very helpful on mine.

Also on that pic I don't see locking pin for the vertical adjustment - maybe it is on the backside - but I consider that mandatory. Don't want to leave the hydraulic jack holding it up.

I would still incorporate a locking ring on the spindles and pins on the vertical sections. I'm basing mine off of what MP&C built since my next one is a 55 wagon.

John

'68 Coronet R/T

Oldtimer

Update:

I raised the front by cranking on the handle to center it at top of transmission tunnel.

Raised the back in the same manner to center on the trunk lid key hole.

This got me really close as I could rotate the car 90 degrees without much effort.

With the car at 90 degrees I could see the rocker panel area was near parallel to the floor but the back was too low and this caused the quarter panel to contact the connecting rail. So I raised the back using the hydraulic jack to get everything level and now it will rotate all the way around.

Welded in two small patches, one on the rocker panel and one on the lower rear quarter. It was so much easier that I kept saying to myself, you should've bought one of these 10 years ago. LOL

I raised the front by cranking on the handle to center it at top of transmission tunnel.

Raised the back in the same manner to center on the trunk lid key hole.

This got me really close as I could rotate the car 90 degrees without much effort.

With the car at 90 degrees I could see the rocker panel area was near parallel to the floor but the back was too low and this caused the quarter panel to contact the connecting rail. So I raised the back using the hydraulic jack to get everything level and now it will rotate all the way around.

Welded in two small patches, one on the rocker panel and one on the lower rear quarter. It was so much easier that I kept saying to myself, you should've bought one of these 10 years ago. LOL

MJM

Promoted Users

Update:

I raised the front by cranking on the handle to center it at top of transmission tunnel.

Raised the back in the same manner to center on the trunk lid key hole.

This got me really close as I could rotate the car 90 degrees without much effort.

With the car at 90 degrees I could see the rocker panel area was near parallel to the floor but the back was too low and this caused the quarter panel to contact the connecting rail. So I raised the back using the hydraulic jack to get everything level and now it will rotate all the way around.

Welded in two small patches, one on the rocker panel and one on the lower rear quarter. It was so much easier that I kept saying to myself, you should've bought one of these 10 years ago. LOL

Thanks for updating your experience. This is a very good informative thread on setting up a Rotisserie properly. Lots of great replies in this thread.

Two thumbs up !

MP&C

Member

The pic I posted was to reference the worm gear only which is similar a right angle gearbox. This configuration makes near imposible to turn the output shaft on it's own. The only way they will turn without the input turning is if the main gear shears the teeth off or it shears the wood drift key.

I would still incorporate a locking ring on the spindles and pins on the vertical sections. I'm basing mine off of what MP&C built since my next one is a 55 wagon.

John

I can say when the CG is adjusted correctly you can rotate it with one hand and it stops where you put it. If the CG is off, it can take you for a ride.. Here's the plans for mine:

Photo Storage

Store your photos and videos online with secure storage from Photobucket. Available on iOS, Android and desktop. Securely backup your memories and sign up today!

.

'68 Coronet R/T

Oldtimer

Yes, sir. That's where it is now. I was actually surprised at how easy I can move it and it just stays where I put it. Makes it easy to lock in place.I can say when the CG is adjusted correctly you can rotate it with one hand and it stops where you put it. If the CG is off, it can take you for a ride.. Here's the plans for mine:

Photo Storage

Store your photos and videos online with secure storage from Photobucket. Available on iOS, Android and desktop. Securely backup your memories and sign up today!app.photobucket.com

.

Lizer

Mad Scientist

I paid $800 for my big rotissierie brand new from a guy locally who was selling it. I think he had paid nearly double that for it, and $450 for my smaller rotisserie which was a home made unit.

No way I could make either of those myself for that cost. Just buying the square tubing to run underneath my truck box was over $100 as seconds.

No way I could make either of those myself for that cost. Just buying the square tubing to run underneath my truck box was over $100 as seconds.

'68 Coronet R/T

Oldtimer

I was very happy to get this one, since I have been looking for months now and a used rotisserie in good condition is very hard to find.

Saw one that the guy was asking $1200 for but looked rusted and had very small casters on it. That helped make up my mind to buy the new one.

Saw one that the guy was asking $1200 for but looked rusted and had very small casters on it. That helped make up my mind to buy the new one.

Lizer

Mad Scientist

There are holes in the vertical tubing for the locking pin. You can see them in the pic. I think the big flat square piece behind the crank handle is covering up the locking pin from the picture.Unnecessary IMO. When you get the CG right, one guy can rotate the car, almost with one hand, very easily.

Not sure what is in your plans, but that pic doesn't include a locking ring/pin for rotation.

I found it very helpful on mine.

Also on that pic I don't see locking pin for the vertical adjustment - maybe it is on the backside - but I consider that mandatory. Don't want to leave the hydraulic jack holding it up.

You can see both on the Tuxedo model I bought

View attachment 24398

'68 Coronet R/T

Oldtimer

It has Socket head screws in the back to lock it at any height setting.

Right now, I do have the locking pins in also.

Right now, I do have the locking pins in also.

JimKueneman

Mopar Nut

I looked at those too.... for the A100 or Dart Wagon I am not going to restore. I have found the A Bodies like to be balanced with the pivot just above the bumper line.I bought it from a place in Gilbert, Arizona called Quick Lift USA.

They quoted me $2000 delivered but I got the "cash" price and went and picked it up for $1550.

JimKueneman

Mopar Nut

I paid $800 for my big rotissierie brand new from a guy locally who was selling it. I think he had paid nearly double that for it, and $450 for my smaller rotisserie which was a home made unit.

No way I could make either of those myself for that cost. Just buying the square tubing to run underneath my truck box was over $100 as seconds.

I priced the metal (cut to size) for one recently and it was just short of $1000... figure in the welding time and $1500 with hydralics is cheap.

Last edited:

JimKueneman

Mopar Nut

Guess I was actually looking at this one in Mesa. Same thing?

www.facebook.com

www.facebook.com

Log into Facebook

Log into Facebook to start sharing and connecting with your friends, family, and people you know.

www.facebook.com

www.facebook.com

'68 Coronet R/T

Oldtimer

Yes, sir that is the same company I got mine from.Guess I was actually looking at this one in Mesa. Same thing?

Log into Facebook

Log into Facebook to start sharing and connecting with your friends, family, and people you know.www.facebook.com

Dean Jenkins

Promoted Users

That will make the next restoration, that you're not doing, much easier.Guess I was actually looking at this one in Mesa.