6

6686mustang

Brian is staying clean on this one! As always - Outstanding workmanship!

6686mustang;26508 said:Overall - how would you rate the Dynacorn body? Good quality? I've been checking their site for a while. Their products look good - thanks to your extensive back round in Mustang construction - their are issues some others may not notice. I would have thought there would have been less panel alignment issues. Thanks for taking us through all the steps on this one!

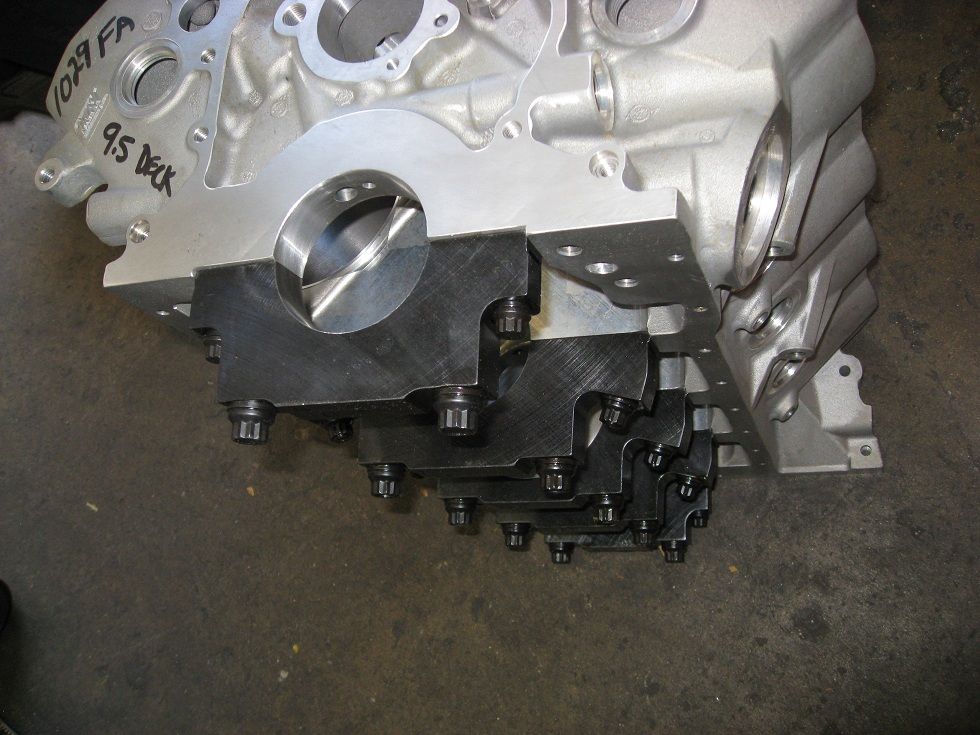

cjetmech;27241 said:Niiiiiiice! Whats that other block and monster lookin crank in the backround?

stangnet33;28688 said:Things are looking great ! Just wondering with all the bigger issues you are having with Dynacorn are you relaying this info back to them so they can make the necessary corrections ? Also what issue of MM&F is that mod for the hood latch in ? Thanks