S

stangnet33

rusty428cj;33236 said:I have had questions wanting to know what issue this would be in and I'm happy to say it's in the March issue that just went to the printers.

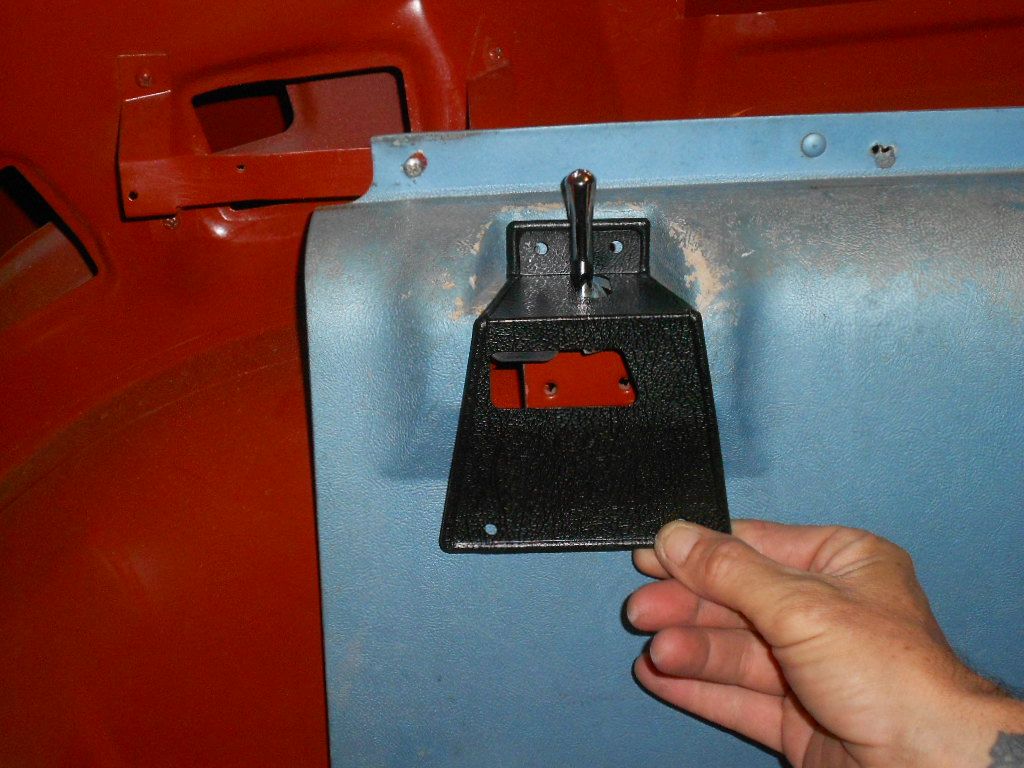

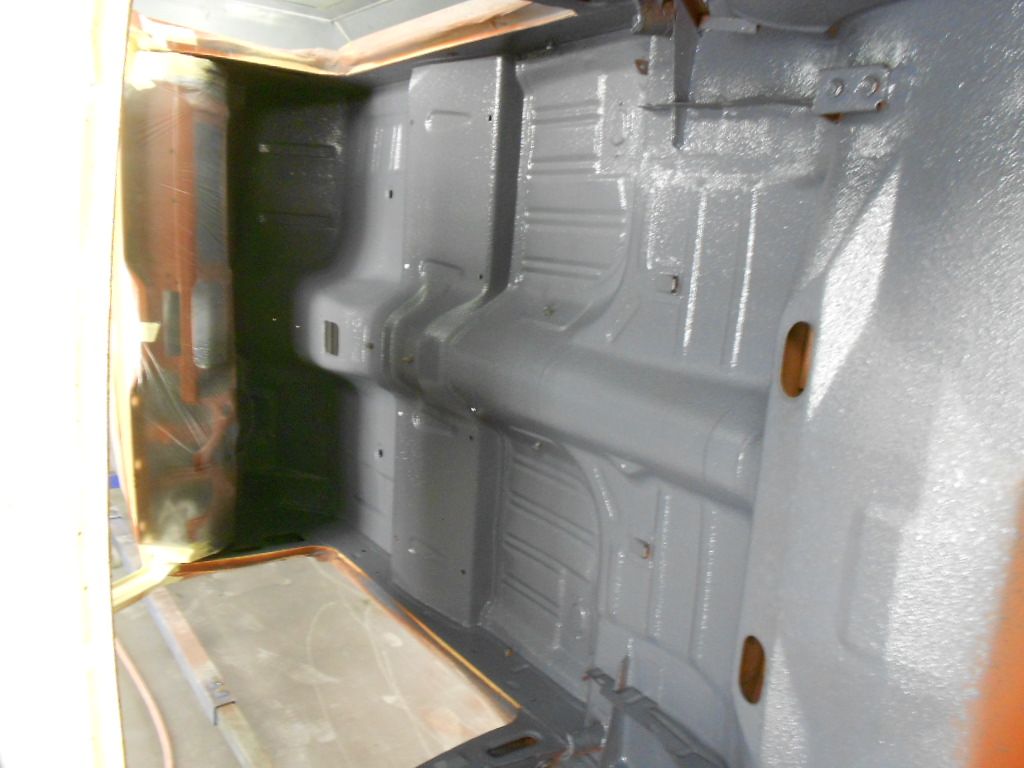

This is what Brian has been fabricating. It is an under the dash hood release. The hood required a lot of fabrication along with this latch that came off of another Ford. To find out all the details you will have to read the build story in an upcoming issue of Modified Mustangs & Fords magazine.

Thanks for the update rusty ! Look forward to the read. Things are looking great !