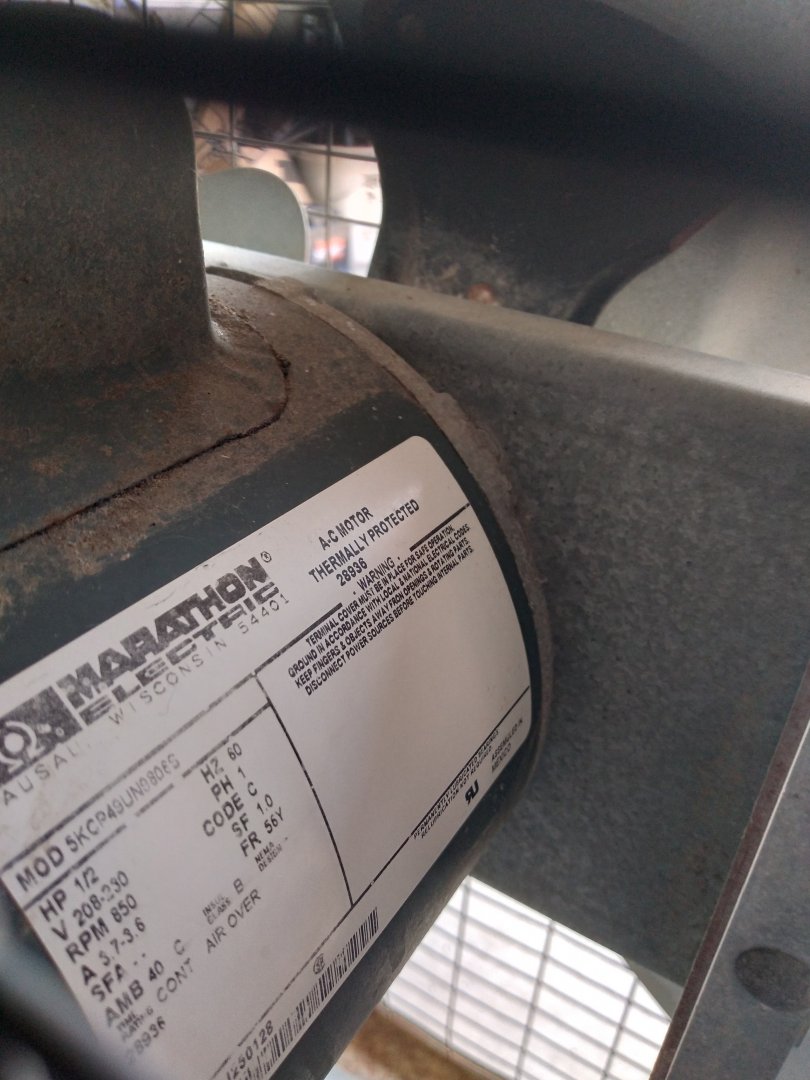

A fan has to push everything it pulls. Looking at the fan as it sits in the pic above, the blade would be turning counterclockwise to draw air across the motor and blow it out the opposite side.

FWIW, standard terminology for motor rotation is based on viewing the motor from the end opposite the shaft. The current rotation is counterclockwise.

If you reverse the motor and leave everything else as is, the fan will handle very little air at all. With few exceptions, fan blades are designed for rotation in one direction only.

To pull air out of the room, simply set the fan in the opening with the motor toward the room and turn it on.

Assuming you have no obstructions on the outlet of the fan, it should handle whatever it can draw into the room. That cfm is determined by the specific fan curve for that fan and its ability to develop static pressure. Most propeller fans are for use in free air and won't develop much static. A spray booth fan is designed to develop static pressure so that it can overcome flow resistance in ductwork. If you look at a picture of a booth fan, it will look entirely different than the fan you have. The fact that your fan has a 1/2 hp motor indicates it won't develop much static pressure. In comparison, a true spray booth fan that size would typically have a motor in the 5hp to 7.5 hp range. In plain terms, a fan that won't develop significant static pressure will be affected by any restriction on either the entering or leaving side in a manner that causes the cfm it will handle to drop off very quickly.

If you plan to have a pair of 20" box fans as the only openings to draw air into the room, you will likely have problems. A 20" box fan will handle 1800 to 2000 cfm. So two of them will handle less than half the capacity of the big fan. Therefore the two box fans will become an obstruction to air flow rather than an enhancement. The likely result is a couple streams of air traveling from the box fans directly to the big fan rather than uniform flow across the cross section of the booth which is what's needed to efficiently clear overspray.

You'd be better off to construct a filter bank at the entering end of the booth rather than trying to push air in with box fans. Typical sticky filters for spray booth inlet use are rated for 100 cfm face velocity. So, to allow 10,000 cfm to enter the booth, you'd need 10,000/100= 100 sq ft of filter area. Yeah, its a lot of filters and a lot of area, but that's what's proven to produce somewhat uniform flow across the booth's cross section. The 100 sq ft inlet area will minimize pressure drop thru the filters and will allow your big fan to actually handle something near its free air rating. My halfway educated guess would be that the big fan will handle twice the air it would handle if using the box fans as the inlet.