You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Weld or Upol fiberglass filler to fill holes ?

- Thread starter MJM

- Start date

Chris_Hamilton

Trying to be the best me, I can be

Weld. Always IMO. If you put filler of any type over those holes it will eventually fail. Fiberglass enhanced filler is not really waterproof. It works good for fiberglass repairs and is a favorite of cave and pave collision guys. Something that you are taking a lot of care with and want to last...no.

MIG the holes, and use some cavity wax on the backside. They make kits with extended wands to reach into places like that. It will come on handy on other places on your car as well.

Transtar 4423 Cavity wax and 4471 wand kit. You can get it online or through most Paint Jobbers.

MIG the holes, and use some cavity wax on the backside. They make kits with extended wands to reach into places like that. It will come on handy on other places on your car as well.

Transtar 4423 Cavity wax and 4471 wand kit. You can get it online or through most Paint Jobbers.

MJM

Promoted Users

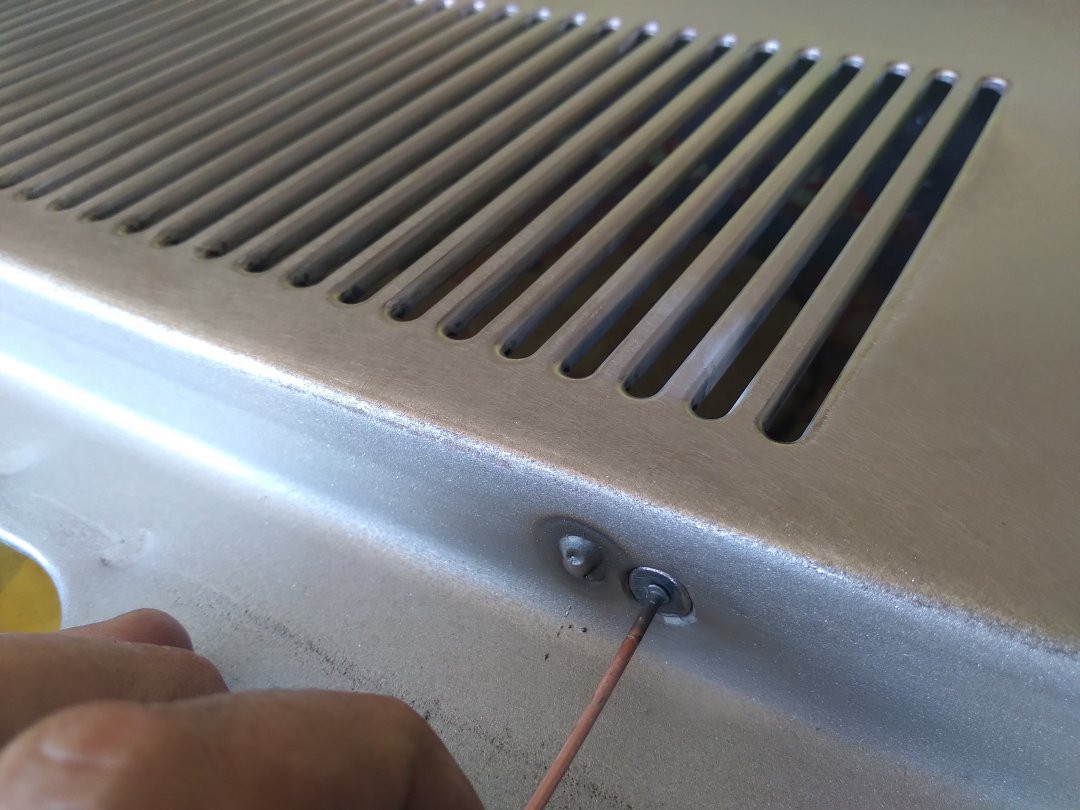

No windshield washers?

Good eye, those holes are indeed windshield spray nozzle holes. Didn't see a need to install them since I can just pull over, have my wife jump out of the car and clean the front window.

I didn't want to clutter the engine compartment with a washer fluid bottle. Yeah I could relocate to the trunk but......

Chris_Hamilton

Trying to be the best me, I can be

I don't see a link?? 3M would be fine. Transtar is usually cheaper and just as good. I included the part numbers in my post above.Thank you, Chris. I Goggled cavity wax and found this kit from 3M.

Is this acceptable?

MJM

Promoted Users

Dean Jenkins

Promoted Users

I bought this tool to punch circles out of sheet metal when filling some holes just like that.

It worked great!

It worked great!

MJM

Promoted Users

I bought this tool to punch circles out of sheet metal when filling some holes just like that.

It worked great!

That's a handy tool. Thanks for sharing.

MJM

Promoted Users

Been researching the application of cavity wax. From my findings, the spray nozzle sprays in a 360 degree direction. This could cause an awful mess to the cowel slates I just prepped for epoxy.

I'm wondering if a direct (spot) spray could be possible by cutting off the wand spray nozzle?

Thoughts?

I'm wondering if a direct (spot) spray could be possible by cutting off the wand spray nozzle?

Thoughts?

MJM

Promoted Users

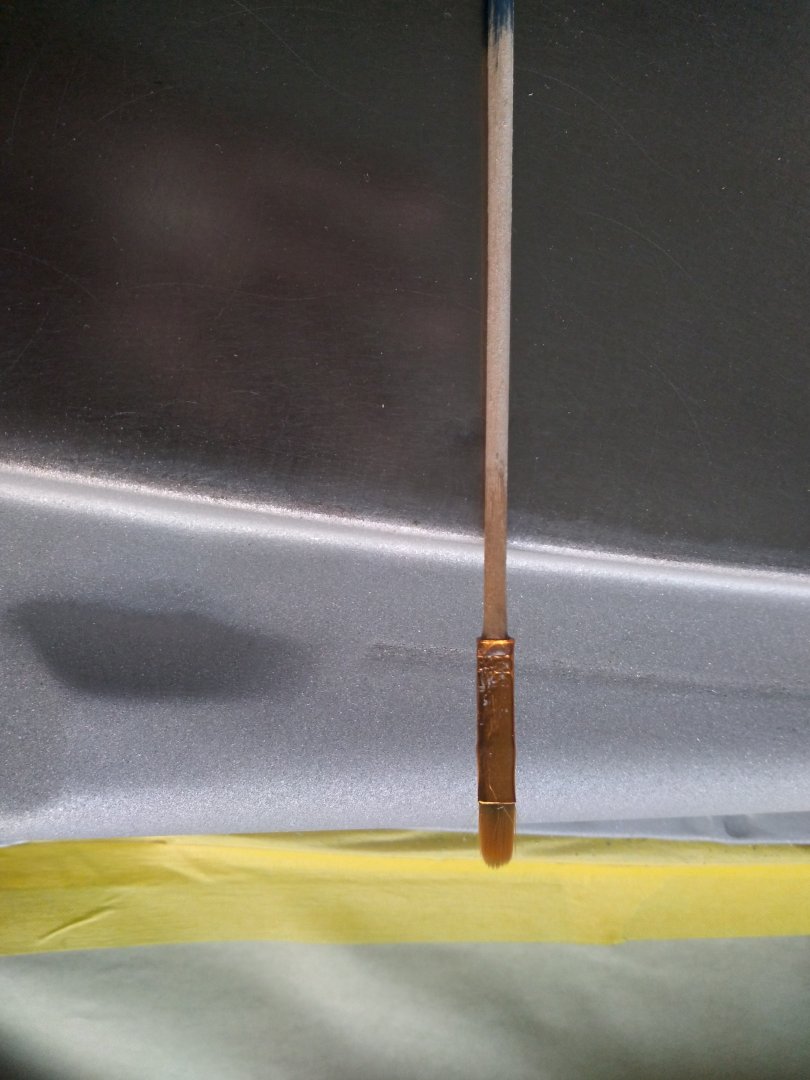

Just checked to see if I could get a small paint brush thru the cowel slates. So I raided my wife's canvas paint brushes, and with a little sanding of the handle and flattening out the metal part of the brush, it fits between the louvers slates. I'll be able to get epoxy on the backside of the welds.

Dean Jenkins

Promoted Users

I have the 3M cavity wax and wands all ready to go for the quarter panel, cowl and assorted voids. But won't use it until all paint/clear is done.I would not use cavity wax there. It will act as a dirt magnet and you will see it through the grille imho. I would use epoxy.

When I do use cavity wax I do it when all the paint work is complete.

Don

Probably will spray it while waiting 2 weeks after spraying clear before cutting/buffing.

No way I want that wax anywhere near a surface that will be painted.

MJM

Promoted Users

I have the 3M cavity wax and wands all ready to go for the quarter panel, cowl and assorted voids. But won't use it until all paint/clear is done.

Probably will spray it while waiting 2 weeks after spraying clear before cutting/buffing.

No way I want that wax anywhere near a surface that will be painted.

Valid point, I didn't even think about the cause and effect of the wax before spraying the car. At least I now have been exposed to the product, and am understanding when and how to use it.

MJM

Promoted Users

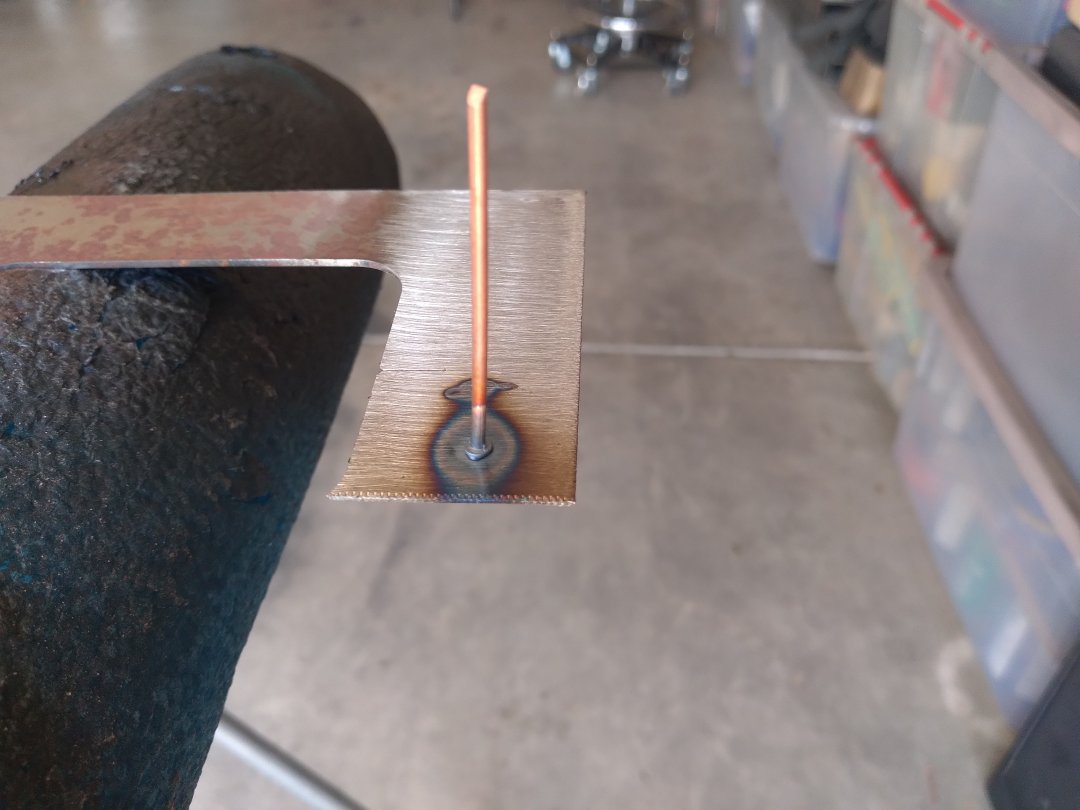

Since Dean wouldn't rent me his hole punch tool for the day (wink wink ), I ended up making my own plugs.

Picked this tip up from that guy in Canada, Fritz, I believe is his name.

Used a welding stud and welded it to some 19 gauge. Then cut a square out of it and chucked it up in a drill. Using my die grinder, grinded it down to the desire circumference.

Picked this tip up from that guy in Canada, Fritz, I believe is his name.

Used a welding stud and welded it to some 19 gauge. Then cut a square out of it and chucked it up in a drill. Using my die grinder, grinded it down to the desire circumference.

Dean Jenkins

Promoted Users

Since Dean wouldn't rent me his hole punch tool for the day (wink wink ), I ended up making my own plugs.

Picked this tip up from that guy in Canada, Fritz, I believe is his name.

Used a welding stud and welded it to some 19 gauge. Then cut a square out of it and chucked it up in a drill. Using my die grinder, grinded it down to the desire circumference.

Dean Jenkins

Promoted Users

Fitzee from Newfoundland. Good info and fun to watch on YouTube.

I did that several times before getting the punch tool. About half the time the stud came off, everything went flying and I had to start over. But it worked.

I did that several times before getting the punch tool. About half the time the stud came off, everything went flying and I had to start over. But it worked.