jlcustomz

evil painter

Part of my day job these days has been an increasing amount of painting entrance doors with just commercial waterbourne acrylic paint.

Not much work room right now for multiple jobs, prep takes up most of my time, do installs, repairs etc, & a lot of customers want their door panels 2 colors. Getting hard to have time for 1 color to dry enough for tape not to risk pulling up paint. So been working on technique to spray 2 colors at 1 time on same door panel semi- nonstop. Have my shop made rotisserie setups to spin doors & paint flat or sideways & using a 6 stage titan turbine sprayer with pressure assisted gravity feed guns (2 right now).They're ok for what I'm using them for with paint additives to slow initial dry time & easy to vary trigger holding for slower finer flow rate without constantly adjusting gun.

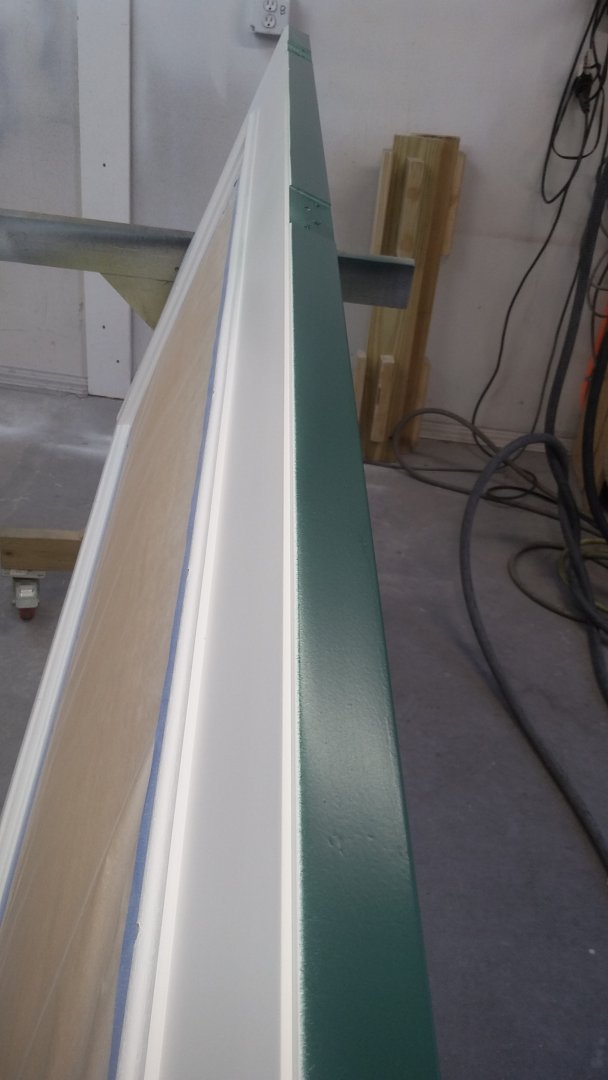

In the example pictured I sprayed a light coat of green, fine spraying as little as possible on white edge while thoroughly covering green up to it. The edge to be green gets moderately coated spraying down. After a few minutes of setting up white side is sprayed , carefully up to green edge without much overspray & white edge sprayed pointing down. Little longer setup & light second coat. Few minutes setup & repeat green with spraying across door this time to miss hitting white edge with green.

Yea not car stuff, but we gotta find ways to do some things quicker to make a living.. I get a softer edge between colors which is more consistent than taped edge on a less than perfect rounded edge looks.

Not much work room right now for multiple jobs, prep takes up most of my time, do installs, repairs etc, & a lot of customers want their door panels 2 colors. Getting hard to have time for 1 color to dry enough for tape not to risk pulling up paint. So been working on technique to spray 2 colors at 1 time on same door panel semi- nonstop. Have my shop made rotisserie setups to spin doors & paint flat or sideways & using a 6 stage titan turbine sprayer with pressure assisted gravity feed guns (2 right now).They're ok for what I'm using them for with paint additives to slow initial dry time & easy to vary trigger holding for slower finer flow rate without constantly adjusting gun.

In the example pictured I sprayed a light coat of green, fine spraying as little as possible on white edge while thoroughly covering green up to it. The edge to be green gets moderately coated spraying down. After a few minutes of setting up white side is sprayed , carefully up to green edge without much overspray & white edge sprayed pointing down. Little longer setup & light second coat. Few minutes setup & repeat green with spraying across door this time to miss hitting white edge with green.

Yea not car stuff, but we gotta find ways to do some things quicker to make a living.. I get a softer edge between colors which is more consistent than taped edge on a less than perfect rounded edge looks.