You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Shrinking 19 gauge metal with heat question.

- Thread starter MJM

- Start date

Chris_Hamilton

Trying to be the best me, I can be

Ideally you don't want to quench steel. I know it's all over the internet and even some books, but quenching hardens and makes it brittle locally in that spot.Is there a certain temperature the metal needs to be before hitting it with a damp cool towel?

The heat sources I have are, map gas, heat gun with max 1200 degree, and stud welder. I do have a temperature gun so I can monitor the metals temp.

Thank you,

If it's minor shrinking it's not as big a deal but it's not good practice.

For small spots the stud gun with a shrink tip is excellent. Let it cool naturally. Larger areas where you would use a torch you would heat and then lightly tap the area with a body hammer.

There are some good threads on here covering this topic. Search and read some of them. I'll look up the ones I'm thinking of when I get some time and post a link here.

Chris_Hamilton

Trying to be the best me, I can be

Not saying it doesn't work it hardens/brittles the steel in that area which can be an issue. I've seen cars that had been worked before with heavy quenching crack in that area after being hit. The old timers I learned from and top guys that I respect, Kent White, Peter Tommasini never do it. That is good enough for me. I don't use a shrinking disc either, but that's another story. That being said the vast majority of the shrink is from the heat, very little comes from the quenching.

Chris_Hamilton

Trying to be the best me, I can be

Another example Mike. Say you overshrink an area that you quenched several times. It's going to be harder to stretch that area to work it back up when it's quenched.

MikeS

Camaro Nut

I work it in small steps and each step is different (mainly how much heat is applied) than the previous depending on the results. That's where the experience comes in as to when to stop the cycle. Plus, the compressed air doesn't cool it as quickly as when using water and is more controllable.Another example Mike. Say you overshrink an area that you quenched several times. It's going to be harder to stretch that area to work it back up when it's quenched.

How about a picture of what you are trying to shrink.Is there a certain temperature the metal needs to be before hitting it with a damp cool towel?

The heat sources I have are, map gas, heat gun with max 1200 degree, and stud welder. I do have a temperature gun so I can monitor the metals temp.

Thank you,

theastronaut

Promoted Users

Just enough to turn blue, start with very small spots- dime size or less. No need for the metal to turn red hot. Do one spot, let the panel cool down to room temp naturally, check the shape to see how much the panel moved then judge where your next spot/spots needs to be shrunk. If the panel has high and low spots from damage then you'll need to hammer and dolly as much of that out as possible, and focus the shrinking on the damaged areas that stretched the most. If its a flat or low crown panel a shrinking disk will work the fastest and will straighten the metal as it shrinks the high spots down.

MJM

Promoted Users

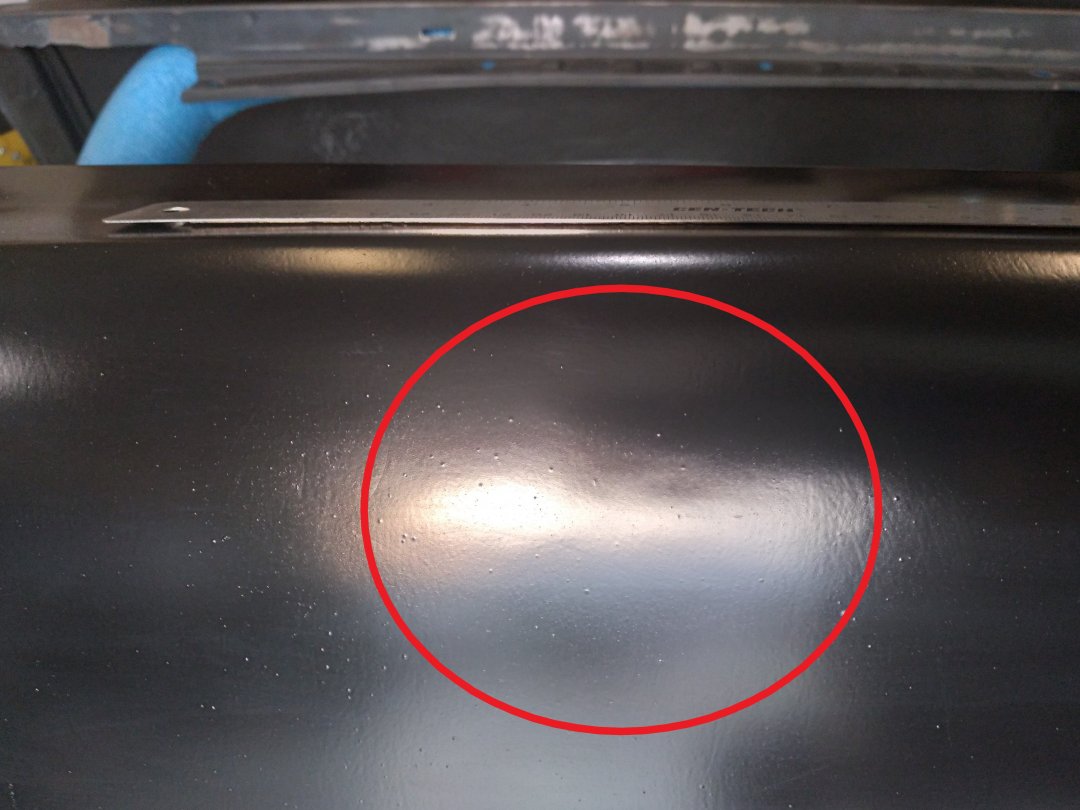

This is the best picture I could take to show a high spot. A little background about that dent. It was a softball size dent in circumference, with the deepest part of the dent around 3/8" deep. The dent happened when yours truly was pushing the car sideways on wheel dolly's. I used a hammer and dolly off, to get out. I either pushed a little too hard on the dolly from the back side or, one too many taps with the hammer on the perimeter of the dent. When I first got the dent out, the metal oil canned...............so I apply pressure on the back side of the fender in the middle of the dent and continued to hammer the perimeter of the dent. That seems to work and the metal no longer oil canned.

Running my hand over the area tells me it's a tad high, so I thought shrinking would be the next step? I'm afraid if I dolly off and take a few taps to the cent to lower the metal, I get that oil canning again?

Red circle indicated size of dent. The shinning spot is the high spot.

Running my hand over the area tells me it's a tad high, so I thought shrinking would be the next step? I'm afraid if I dolly off and take a few taps to the cent to lower the metal, I get that oil canning again?

Red circle indicated size of dent. The shinning spot is the high spot.

MJM

Promoted Users

A stud welder with a shrinking tip will keep you out of trouble imho.

Don

I looked for a shrinking tip but, all I could find was an H&S tip made for their stud welder. I have a very expensive Harbor Freight stud welder that has stud screw in tips. I did however look for some Youtube videos and a lot of guys just used the stud welder with no special shrinking tip.

Thank you for the suggestion.

Chris_Hamilton

Trying to be the best me, I can be

Run some sandpaper over it, 45 degree angle to the spot would work best. Then take a pic and post again please. Hard to tell anything from your pic.

If you have a shot bag dolly you could place that behind the high and tap with a body hammer. Shot bag will allow it to shrink slightly. A rubber coated dolly would work, just not quite as well.

If you do use heat follow Astro's advice above. Go slow, highlight the highs and work them progressively starting with the highest spot.

If you have a shot bag dolly you could place that behind the high and tap with a body hammer. Shot bag will allow it to shrink slightly. A rubber coated dolly would work, just not quite as well.

If you do use heat follow Astro's advice above. Go slow, highlight the highs and work them progressively starting with the highest spot.

I would use some sandpaper as Chris suggested, then hammer and off dolly the lows and highs as Astronaut said.

But first, I would check the whole panel not just one area, I'm thinking the hit might have pulled some surrounding metal in also, and you narrowed your work to one area.

If that is what happened, then the dolly probably should have been used alone to give an equal hit on the back side of the impacted area, and that would have pushed the surrounding metal out also, which would allow the impacted metal room to come out with ease. Its called roughing it out. Just something to check. I don't like to shrink until I'm sure its needed.

But first, I would check the whole panel not just one area, I'm thinking the hit might have pulled some surrounding metal in also, and you narrowed your work to one area.

If that is what happened, then the dolly probably should have been used alone to give an equal hit on the back side of the impacted area, and that would have pushed the surrounding metal out also, which would allow the impacted metal room to come out with ease. Its called roughing it out. Just something to check. I don't like to shrink until I'm sure its needed.

Like Chris and Chevyman said shrink is the last resort. When working out a dent as yours I will use a dolly on back side an a slapper( old bent file ) with very course teeth on the front side .This slapper will give the metal a slight shrink as it's worked out. This slapper was used by my uncle in the 60's and then given to me. Not used a lot on todays cars

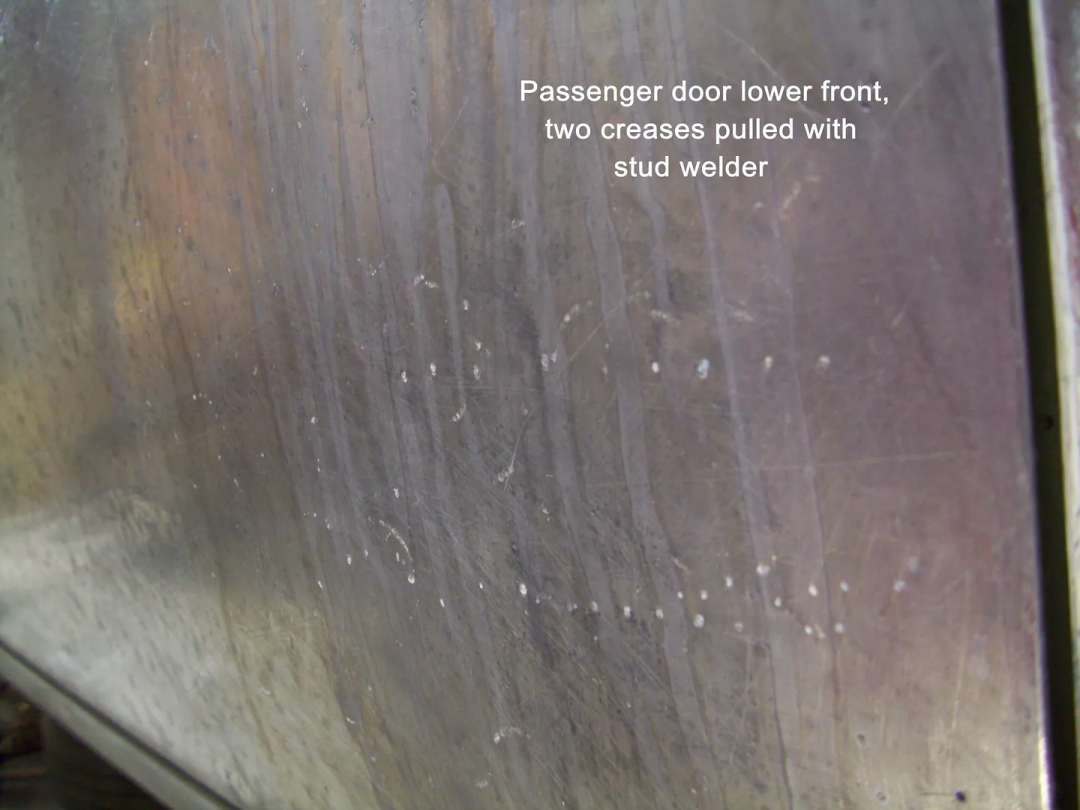

Found this picture of a extra door I have laying around. You can see where someone sanded it, and now it shows the flat area around the crease on both sides. If I was to hold the dolly on the back side of the dent and hammer on those flat areas, it would cause more problems than it would fix.

It needs to be knocked up with just a dolly, and thats what I did with this next door, and finished it off with the stud welder pins.

Not saying this is always the case, I think it depends on the force of the impact. This may be true of a lot of creases, but also for slow motion dents, where there is a lot of force, but applied slowly---such as in your case. The radius of the panel makes a difference also. A thorough inspection of the damage before repairs are started is very helpful.

It needs to be knocked up with just a dolly, and thats what I did with this next door, and finished it off with the stud welder pins.

Not saying this is always the case, I think it depends on the force of the impact. This may be true of a lot of creases, but also for slow motion dents, where there is a lot of force, but applied slowly---such as in your case. The radius of the panel makes a difference also. A thorough inspection of the damage before repairs are started is very helpful.

Run your hand across the sanded area to include beyond it on the left side of the picture. In the picture it seems as though there is a distinct edge/ridge there.But first, I would check the whole panel not just one area, I'm thinking the hit might have pulled some surrounding metal in also,

MJM

Promoted Users

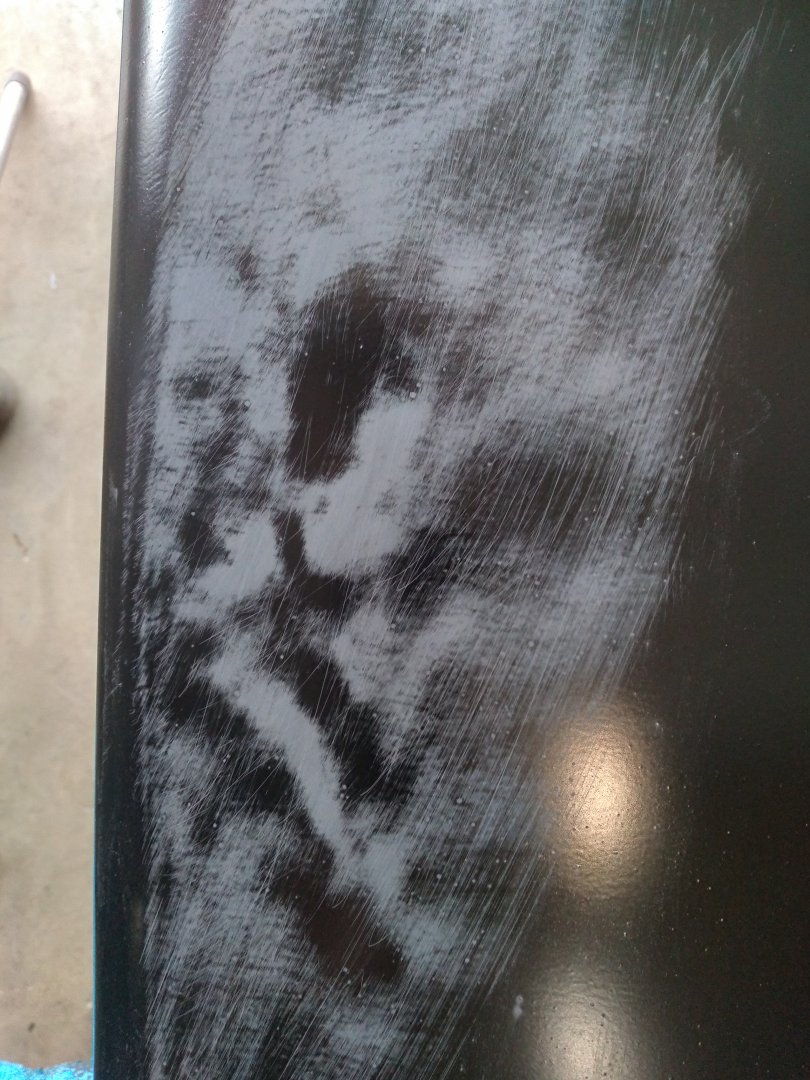

Okay, so I took a chance and tapped the low spots up from the back side, then with my slapper spoon, level it out from the front side. Metal is stiff with no oil canning. Couple pictures of the progression.

Starting point

Getting flatter

Getting better

It feels good to my hand, and I think another coat of epoxy will fill the remaining tiny lows.

Starting point

Getting flatter

Getting better

It feels good to my hand, and I think another coat of epoxy will fill the remaining tiny lows.

Chris_Hamilton

Trying to be the best me, I can be

Good work!  Glad you worked it out.

Glad you worked it out.