R

rayfrausto

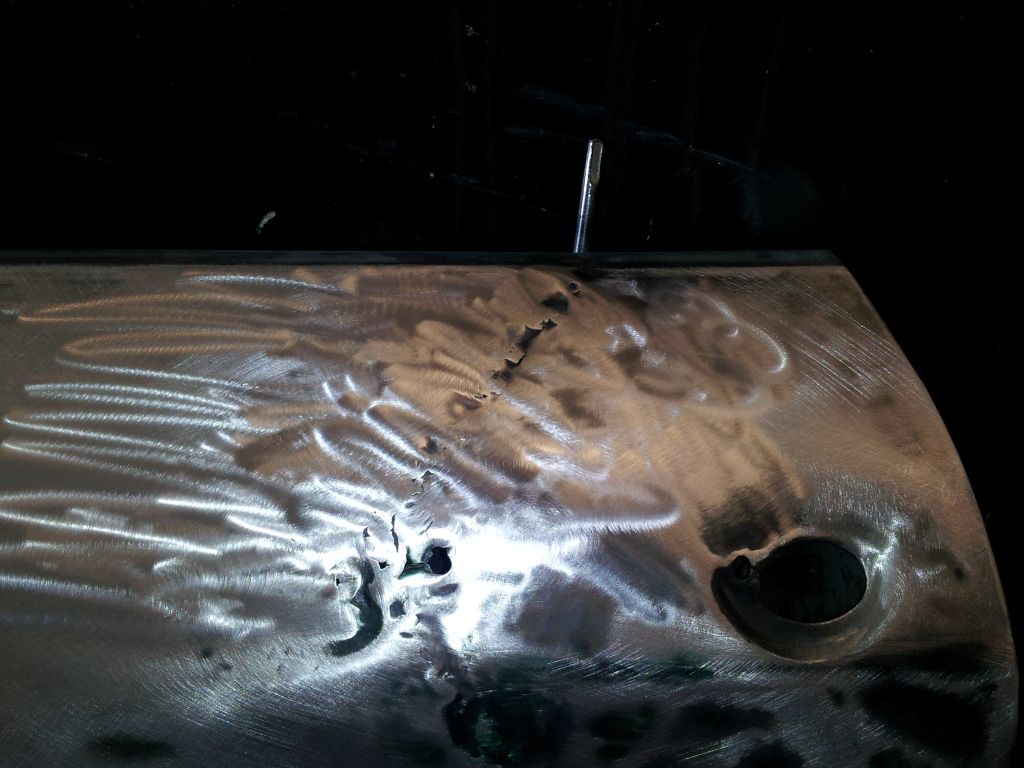

i need advice and help on this door. i want to get it presentable and in epoxy. i need to no where to start and some good advice. very new to this but i need to get the body somewhat presentable and protected in epoxy. so i can focus on the engine and getting her all running squared away. then when funds come in and im down with that do body work or send it out for bodywork. door seem to had dent and who ever attempted drilled holes and try to pull them out. would i just do a lot of hammer and dolly. weld holes and grind?

also im buying a compressor for my house to put outside in the back. really tight on budget and trying to get my stuff squared away so i can start putting this ls1/4l60e combo i got into the engine bay. but ive been looking around and i have enough to get this kobalt 60gal at lowes for $499. would this be okay to start out with and just work around with here and there spraying panel by panel in epoxy.

Horsepower (HP) 3.7

Tank Capacity (Gallons) 60.0

Air Compressor Voltage 230

Amps (Amps) 15.0

Air Delivery SCFM @ 40PSI 13.4

Air Delivery SCFM @ 90PSI 11.5

http://www.lowes.com/pd_54284-1126-...L=?Ns=p_product_qty_sales_dollar|1&facetInfo=

also im buying a compressor for my house to put outside in the back. really tight on budget and trying to get my stuff squared away so i can start putting this ls1/4l60e combo i got into the engine bay. but ive been looking around and i have enough to get this kobalt 60gal at lowes for $499. would this be okay to start out with and just work around with here and there spraying panel by panel in epoxy.

Horsepower (HP) 3.7

Tank Capacity (Gallons) 60.0

Air Compressor Voltage 230

Amps (Amps) 15.0

Air Delivery SCFM @ 40PSI 13.4

Air Delivery SCFM @ 90PSI 11.5

http://www.lowes.com/pd_54284-1126-...L=?Ns=p_product_qty_sales_dollar|1&facetInfo=