serjik911

Promoted Users

Hello everyone,

got a problem, and looks like i cant solve it without help.

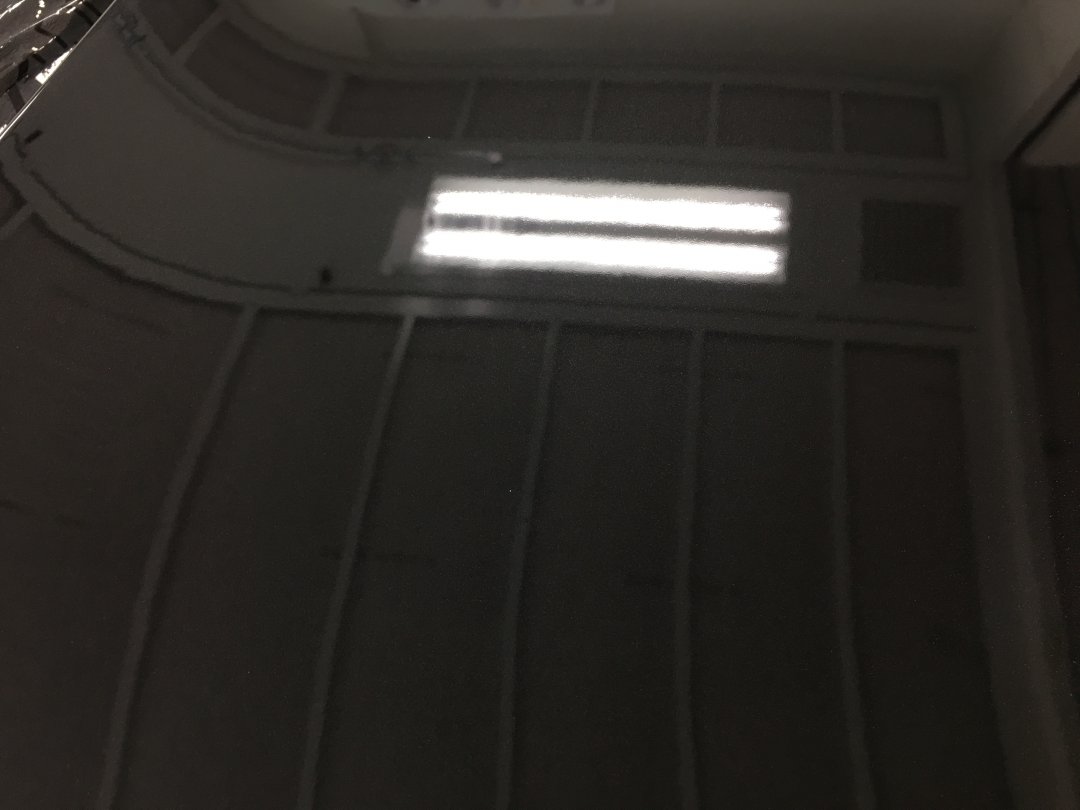

after spraying have a good surface with no runs no dust or anything.

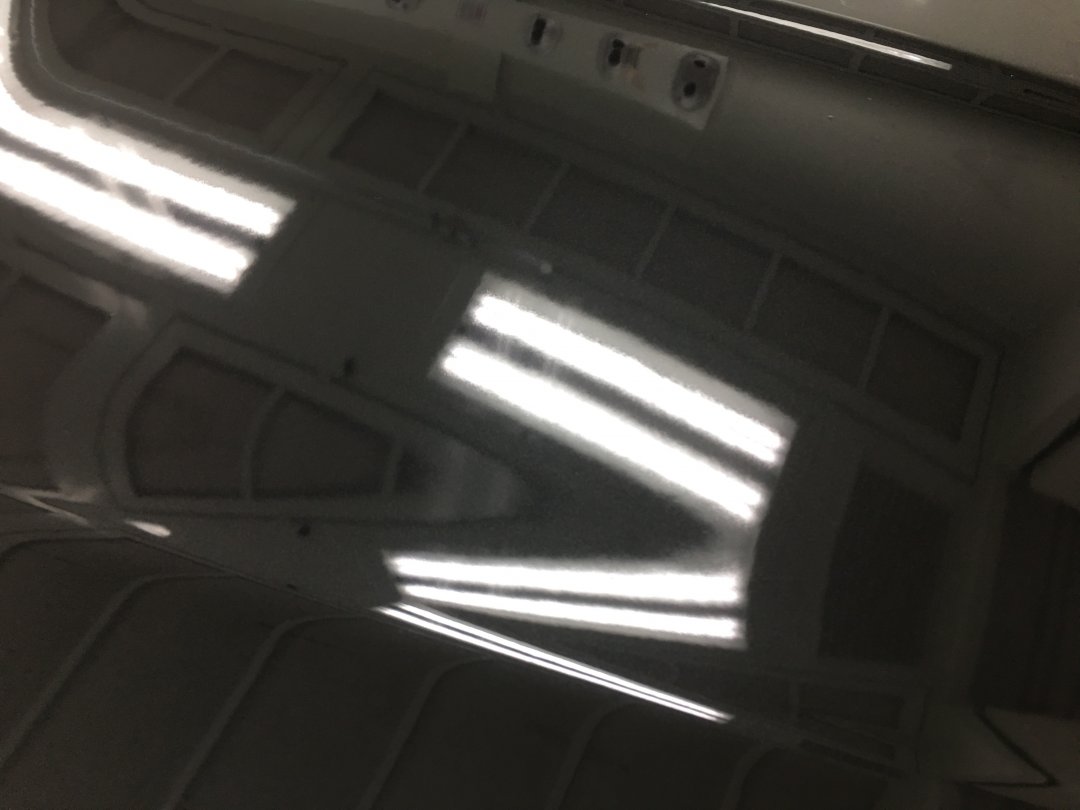

But in 4-5 hours, or if i bake it in 1 hour, i have the clear on my hood with a light boiling. Nothing on other parts. Only hoods.

my first thought was im doing small flash time between coats. waited for 30 mins between coats - same thing.

tried different pressure and different guns - didnt solve it.

tried different clears - same.

tried to do not use bake- same thing next morning.

Between base and clear -15-20 mins and im going with my tack rag thru all panels, and the paint feels completely dry.

another my thought that i put clear too heavy, but i dont have any runs, and on utube isee people smashing clear much heavier than me.... so i really dont know what is going on and i ask you for advice. got this thing for a 2 months already.

got a downdraft booth with a very good air flow.

here are photo of right after sparying and after baking.

got a problem, and looks like i cant solve it without help.

after spraying have a good surface with no runs no dust or anything.

But in 4-5 hours, or if i bake it in 1 hour, i have the clear on my hood with a light boiling. Nothing on other parts. Only hoods.

my first thought was im doing small flash time between coats. waited for 30 mins between coats - same thing.

tried different pressure and different guns - didnt solve it.

tried different clears - same.

tried to do not use bake- same thing next morning.

Between base and clear -15-20 mins and im going with my tack rag thru all panels, and the paint feels completely dry.

another my thought that i put clear too heavy, but i dont have any runs, and on utube isee people smashing clear much heavier than me.... so i really dont know what is going on and i ask you for advice. got this thing for a 2 months already.

got a downdraft booth with a very good air flow.

here are photo of right after sparying and after baking.