Dean Jenkins

Promoted Users

Had an incident last night.

I have an Ingersoll Rand compressor, 5 HP, 60 gallon, twin cylinder, single stage. Had it about a year and it has been great for hobby level work.

My filter for painting is Arrow C7612XL 5 Stage Desiccant System. My piping is all PEX.

I've always left the compressor power on continuously, so I have pressure when I want it. Hasn't been an issue for 25 years . . .

Well, bad habit I guess

Won't be doing that anymore.

Last night the sight glass on the first stage of the Arrow system cracked spontaneously at some point, creating a significant air leak, and resulted in the compressor running continuously for several hours. I found it running this morning at 7:30 AM. I now know it was running at 2AM because a critter triggered my Blink camera and I could hear the compressor running on the video. At least 5 1/2 hours, maybe much more.

When I went to the shop this morning, it was filled with smoke. The electrical motor never overheated and tripped off. But the air pump, and oil, got very hot, too hot to touch, and was smoking.

Had to leave for church and couldn't look into it deeply, so just turned it all off. I got back several hours later. At that point, the compressor seems to work fine, amazingly.

Obviously, I'll change the oil before using it again.

Here is my concern (other than my shop might've burned down): Since the oil was hot enough to be smoking, did smoke/oil mist get pulled into the PEX piping and is the entire distribution/filter system contaminated and need to be replaced?

I drained the drop leg, right before the filters, into a clear container and looked carefully for any oil in the water. No sign of any, but I'm not sure that is conclusive.

Any thoughts welcome.

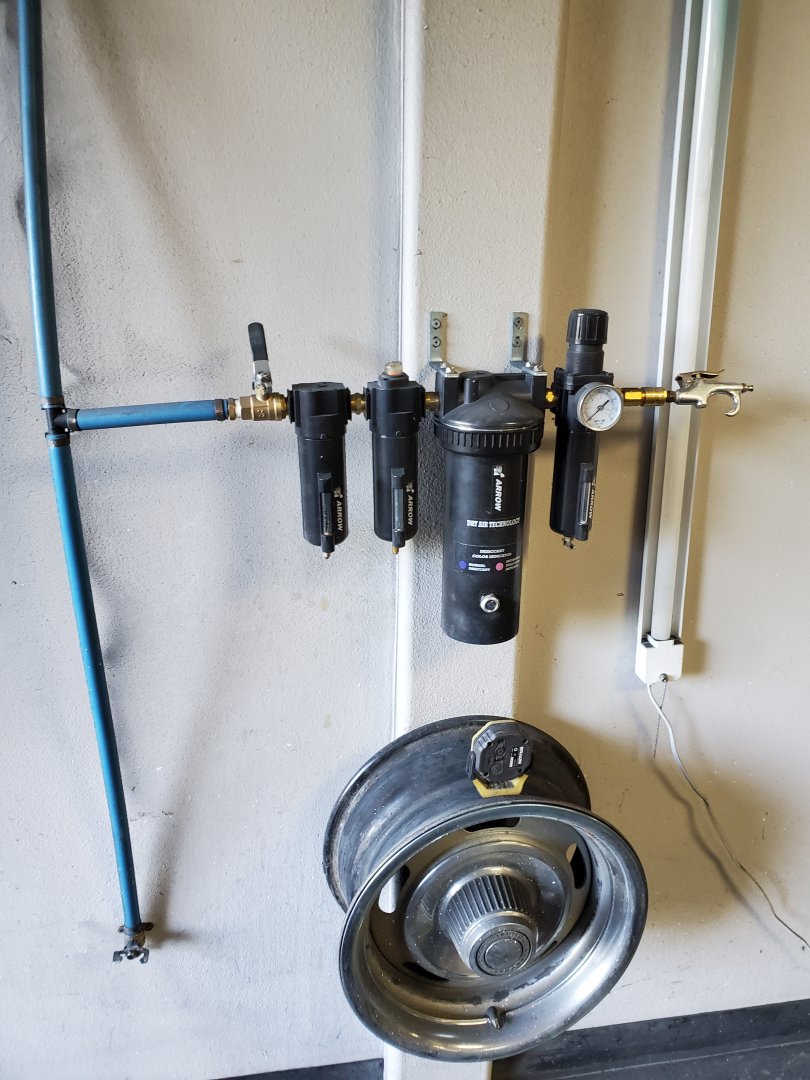

Here is the filter system overview:

Cracked sight glass

I have an Ingersoll Rand compressor, 5 HP, 60 gallon, twin cylinder, single stage. Had it about a year and it has been great for hobby level work.

My filter for painting is Arrow C7612XL 5 Stage Desiccant System. My piping is all PEX.

I've always left the compressor power on continuously, so I have pressure when I want it. Hasn't been an issue for 25 years . . .

Well, bad habit I guess

Won't be doing that anymore.

Last night the sight glass on the first stage of the Arrow system cracked spontaneously at some point, creating a significant air leak, and resulted in the compressor running continuously for several hours. I found it running this morning at 7:30 AM. I now know it was running at 2AM because a critter triggered my Blink camera and I could hear the compressor running on the video. At least 5 1/2 hours, maybe much more.

When I went to the shop this morning, it was filled with smoke. The electrical motor never overheated and tripped off. But the air pump, and oil, got very hot, too hot to touch, and was smoking.

Had to leave for church and couldn't look into it deeply, so just turned it all off. I got back several hours later. At that point, the compressor seems to work fine, amazingly.

Obviously, I'll change the oil before using it again.

Here is my concern (other than my shop might've burned down): Since the oil was hot enough to be smoking, did smoke/oil mist get pulled into the PEX piping and is the entire distribution/filter system contaminated and need to be replaced?

I drained the drop leg, right before the filters, into a clear container and looked carefully for any oil in the water. No sign of any, but I'm not sure that is conclusive.

Any thoughts welcome.

Here is the filter system overview:

Cracked sight glass