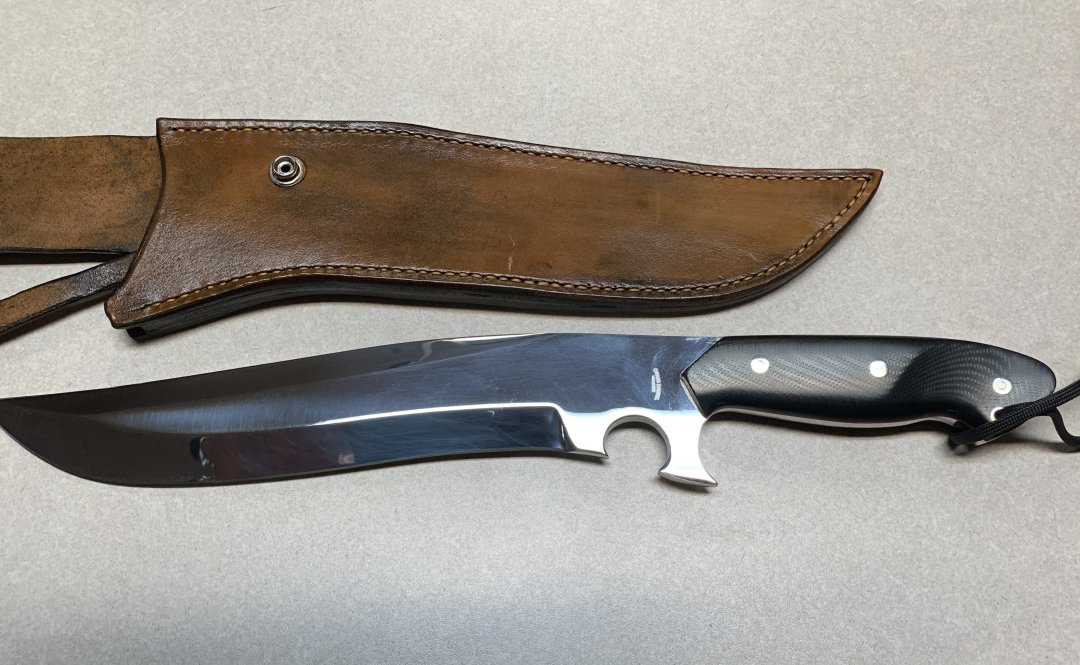

I asked last year to post some custom knives I make and was granted permission to do so. The knife is 16 inches long, 2.5 inches wide and 1/4 inch thick. The steel is 154 CM stainless steel , Handle scales are G 10 with red liners, I made the sheath out of 9-10 oz bull butt.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

A Custom Knife

- Thread starter JC Daniel

- Start date

WOW!!!! Beautiful work.

Take us through the process J.C. How do you make them? I'm particularly curious how you make the handles.

Take us through the process J.C. How do you make them? I'm particularly curious how you make the handles.

I order all my knife bar stock and use my own templates or just come up with a design and cut it out, I pre grind all the bevels and drill all the holes before sending the blades off to have them heat treated. Upon getting the blades from heat treating I finish grind and polish the blades on a Baldor floor buffer, After polish is complete I choose what handle material that I want to use and cut it out a little over sized and drill the holes in the handle material. After the handle holes are complete you dry fit the handle scales together and finish the front of the handles before installing on the knife, I used 2 part epoxy and Loveless bolts to secure the handles. The G 10 on the handles is a man made material and is among the toughest I use, I have to use a metal cutting blade to cut out G 10. I use a flat platen, 8 inch and 10 inch wheels on my machine to do all the bevels and handle shaping, All the bevels and handle shaping are done free hand. This is the only knife I had time to make this year because I am covered up with auto body work, There is 20 - 25 hours labor in the knife and sheath. Come on over to my place and learn to make your own knife!