Mitch

Promoted Users

I had sent the doors and trunk lid to Restoration Specialists in Franklin WI while we were working on the filler/primer stage. When I picked them up, I was shocked at all the hidden damage that had been under the paint. No rust, but, again, they looked like they had been in a demo derby. Only 1 pic of the right door with a large dent that I worked out to only needing a swipe of lightweight filler and then 2k glaze.

I was so disgusted with their condition, I didn't take any more pics. The left door had a crease nearly on the style line from about the center of the door all the way off the back edge. I had seen that crease in the quarter panel too and it went all the way to the bumper. I used hammer and dolly to get much of it out, but when welding the old puller holes used cold water to shrink the area too. It came out decent enough that it, too, only needed a small amount of filler to finish the repair. Karl, the bodyman was amazed at how well I was able to get the metal back in shape. As any production person knows, spending hours removing dents isn't a method used in collision repair. I'm not really "skilled" at it either, but I have lots of time to work on it and learn, and ordering a new door for a 1967 car isn't an option... So, after my time working on them, I shot the outsides with primer and Karl did the filler work. I then scuffed the entire door, as they had been immersed in an EDP tank and are now fulled coated, inside and out. I then sprayed a light coat followed by 2 wet coats all 45 minutes apart and let them sit for 7 days. I use a 75-85 reducer at 20%, as my shop is only about 63 degrees and that slows the curing process and allows the paint to flow out. By laying the parts flat, they looked like glass after a week of sitting like that.

So, after my time working on them, I shot the outsides with primer and Karl did the filler work. I then scuffed the entire door, as they had been immersed in an EDP tank and are now fulled coated, inside and out. I then sprayed a light coat followed by 2 wet coats all 45 minutes apart and let them sit for 7 days. I use a 75-85 reducer at 20%, as my shop is only about 63 degrees and that slows the curing process and allows the paint to flow out. By laying the parts flat, they looked like glass after a week of sitting like that.

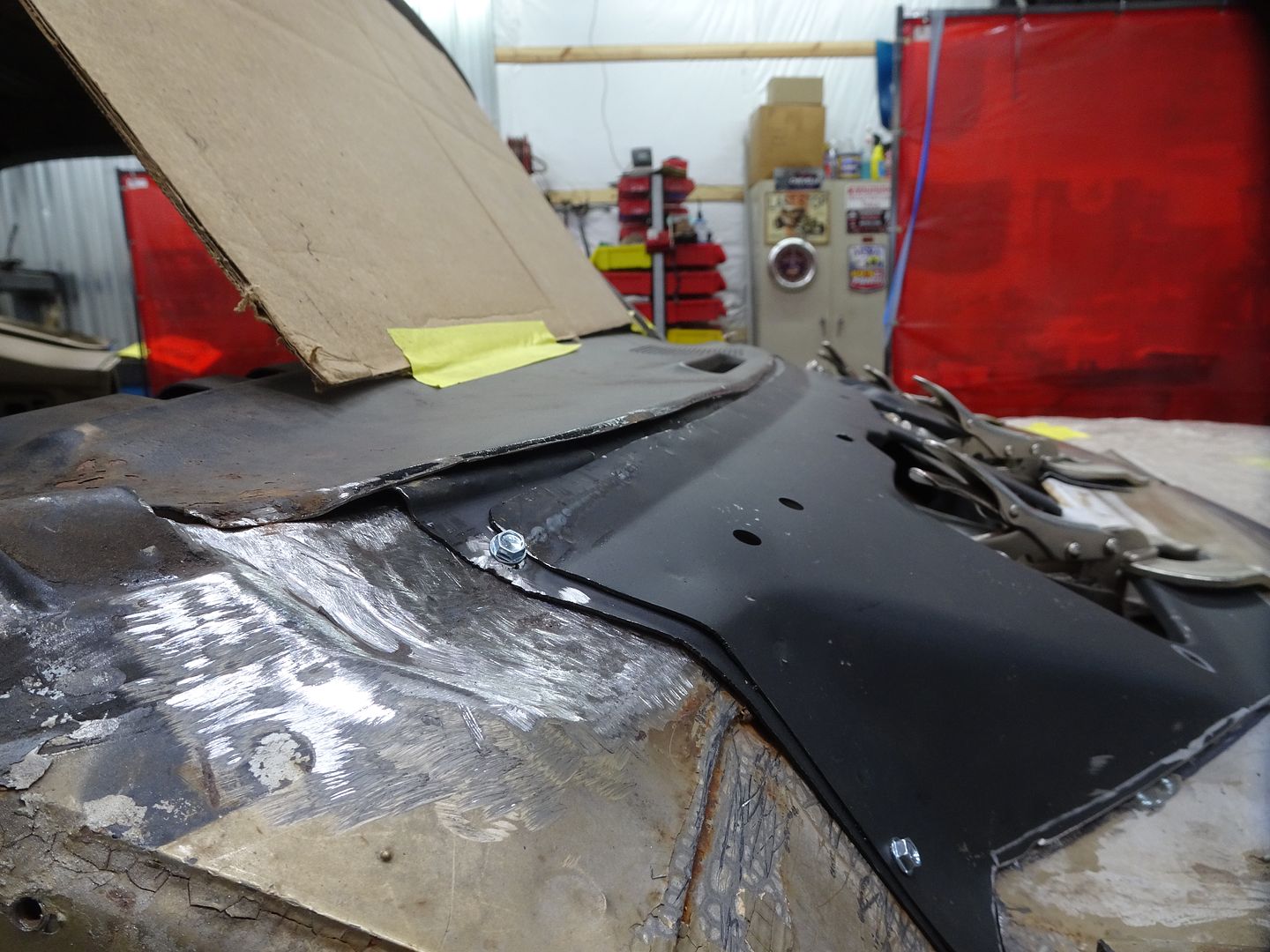

Now we get to my anal side. I've never cared for the large gap the factory left below the trunk lid lip to the tail panel and became of "those" people, who had to weld an 1/8" rod to the lip to close up that gap some.

Once the extension was completely welded on and hand filed to shape, the doors and lid were seam sealed and jammed, along with the trunk opening.

I was so disgusted with their condition, I didn't take any more pics. The left door had a crease nearly on the style line from about the center of the door all the way off the back edge. I had seen that crease in the quarter panel too and it went all the way to the bumper. I used hammer and dolly to get much of it out, but when welding the old puller holes used cold water to shrink the area too. It came out decent enough that it, too, only needed a small amount of filler to finish the repair. Karl, the bodyman was amazed at how well I was able to get the metal back in shape. As any production person knows, spending hours removing dents isn't a method used in collision repair. I'm not really "skilled" at it either, but I have lots of time to work on it and learn, and ordering a new door for a 1967 car isn't an option...

Now we get to my anal side. I've never cared for the large gap the factory left below the trunk lid lip to the tail panel and became of "those" people, who had to weld an 1/8" rod to the lip to close up that gap some.

Once the extension was completely welded on and hand filed to shape, the doors and lid were seam sealed and jammed, along with the trunk opening.