You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1964 Buick Riviera

- Thread starter 64Rivi

- Start date

64Rivi

Promoted Users

Well, life got busy (again) since my last post so had to shelve the Buick for a bit. Been back at it for a few months nows and trying keep the ball moving forward.

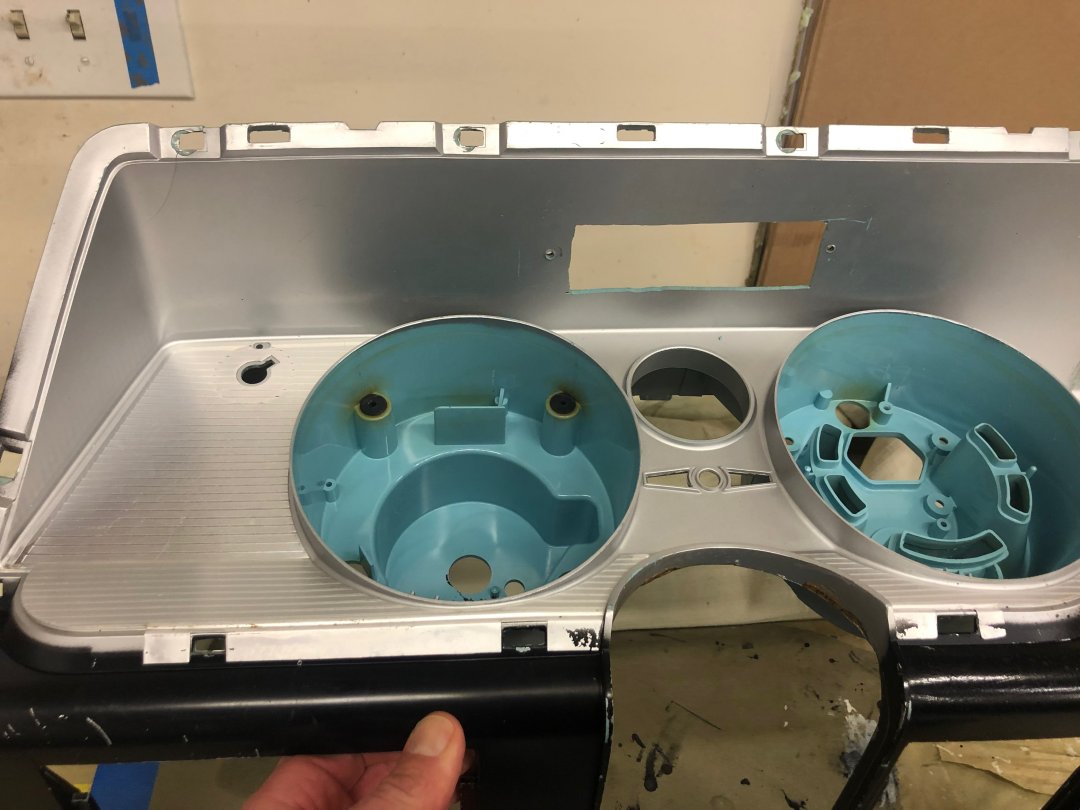

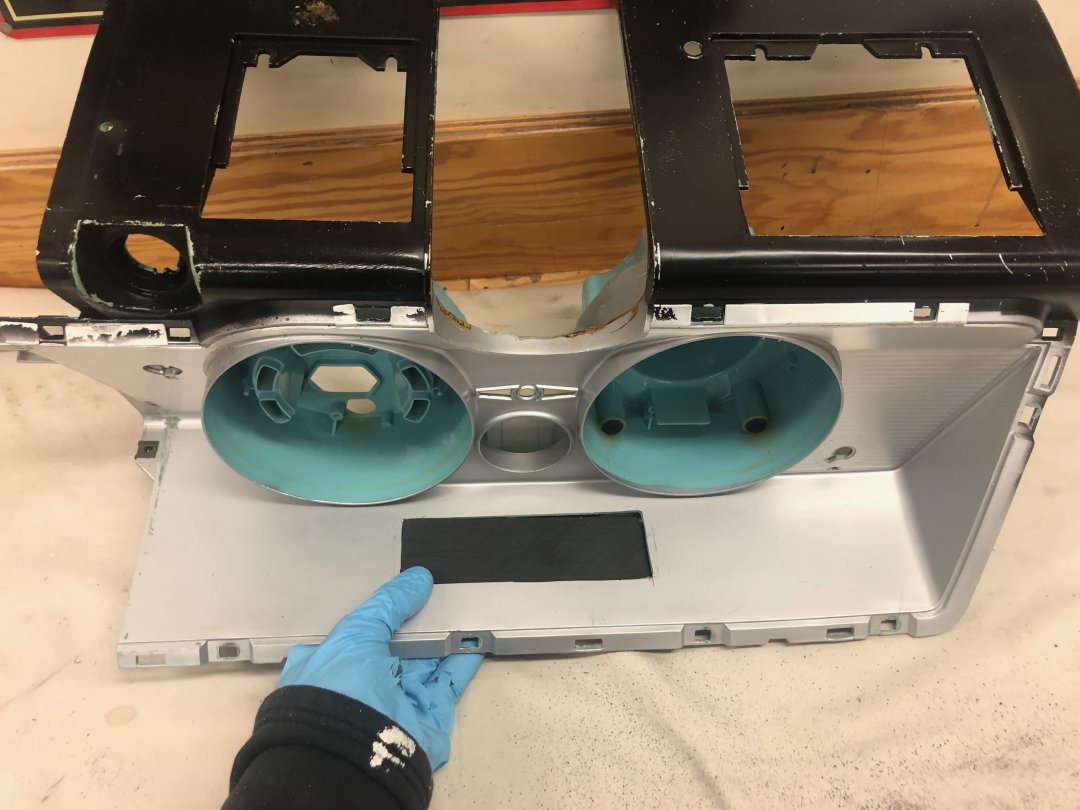

Getting back to the interior, it was time to tackle the dash. The plastic had a bunch of issues that needed repairs. Broken tabs, glove box door hinge mounts broken (notorious in these cars. Bad/ weak design) and a giant hole on the drivers side where the previous owner duplicated the courtesy light on the passengers side.

Fixed most of the tabs and cracks with JB Weld Plastic Bonder and reinforcing mesh including the repair of the big hole.

After the repairs were made, I hit with a couple of coats of 2K and blocked it flat. Surprisingly, the plastic wasn't too out of whack and wavy.

After that, I needed a small amount of Argent Silver to match the original paint. Found the perfect match with Rustoleum Matte Nickel. Nearly identical to the original. Spraying from the can just didn't do it though. The tip doesn't really allow the metallic to lay out and it streaks and mottles like crazy so I cut the can open, let the propellants boil off, added a little retarder and sprayed it from my gun. Perfect.

Next up was the big plan that I've been looking forward to. The first gen Riviera's has a leather option but it was just the leather seat covers. The rest of the interior was left in vinyl (door panels, dash, package tray, knee pad) or painted plastic and metal (console, various filler panels). I wanted to one-up the original and wrap/ upholster the rest with leather and doll the ol' girl up a bit. Nothing outside of original...just in leather.

Starting with the lower dash...

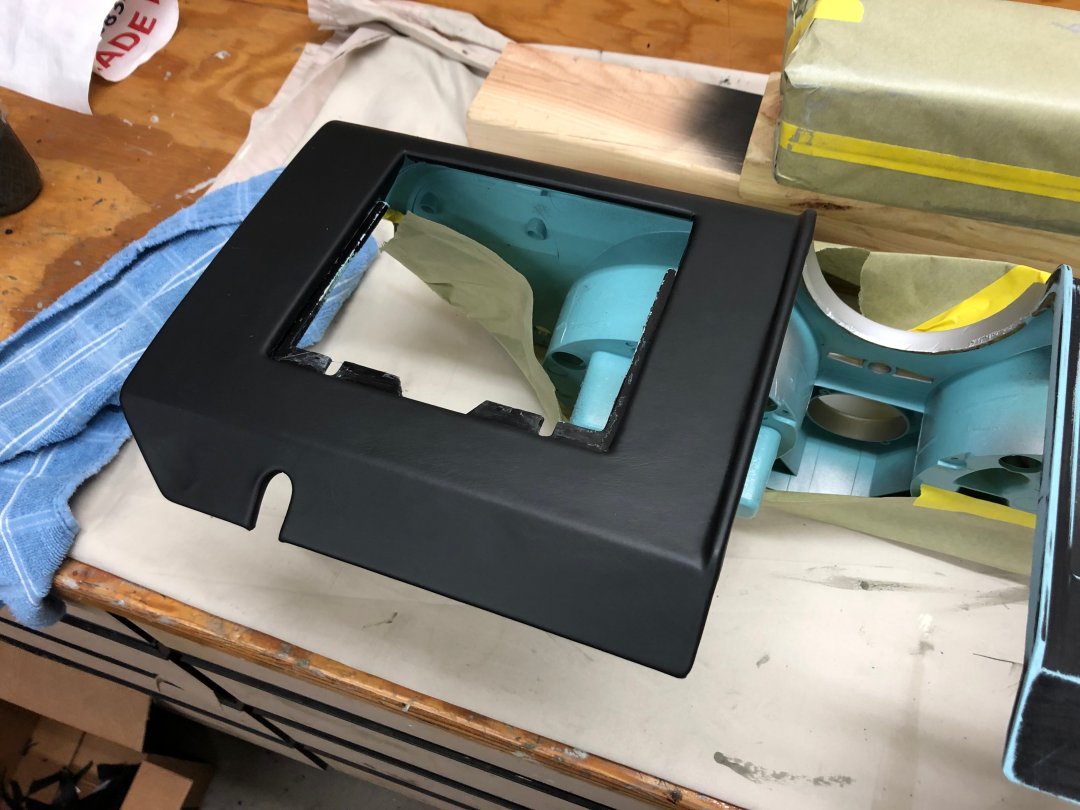

For the chrome trim between panels, I polished the chrome, taped them off and refinished the black centers with SEM matte trim black (love that stuff).

Getting back to the interior, it was time to tackle the dash. The plastic had a bunch of issues that needed repairs. Broken tabs, glove box door hinge mounts broken (notorious in these cars. Bad/ weak design) and a giant hole on the drivers side where the previous owner duplicated the courtesy light on the passengers side.

Fixed most of the tabs and cracks with JB Weld Plastic Bonder and reinforcing mesh including the repair of the big hole.

After the repairs were made, I hit with a couple of coats of 2K and blocked it flat. Surprisingly, the plastic wasn't too out of whack and wavy.

After that, I needed a small amount of Argent Silver to match the original paint. Found the perfect match with Rustoleum Matte Nickel. Nearly identical to the original. Spraying from the can just didn't do it though. The tip doesn't really allow the metallic to lay out and it streaks and mottles like crazy so I cut the can open, let the propellants boil off, added a little retarder and sprayed it from my gun. Perfect.

Next up was the big plan that I've been looking forward to. The first gen Riviera's has a leather option but it was just the leather seat covers. The rest of the interior was left in vinyl (door panels, dash, package tray, knee pad) or painted plastic and metal (console, various filler panels). I wanted to one-up the original and wrap/ upholster the rest with leather and doll the ol' girl up a bit. Nothing outside of original...just in leather.

Starting with the lower dash...

For the chrome trim between panels, I polished the chrome, taped them off and refinished the black centers with SEM matte trim black (love that stuff).

Last edited:

64Rivi

Promoted Users

Next up were all the rest of the bits to fill up the holes.

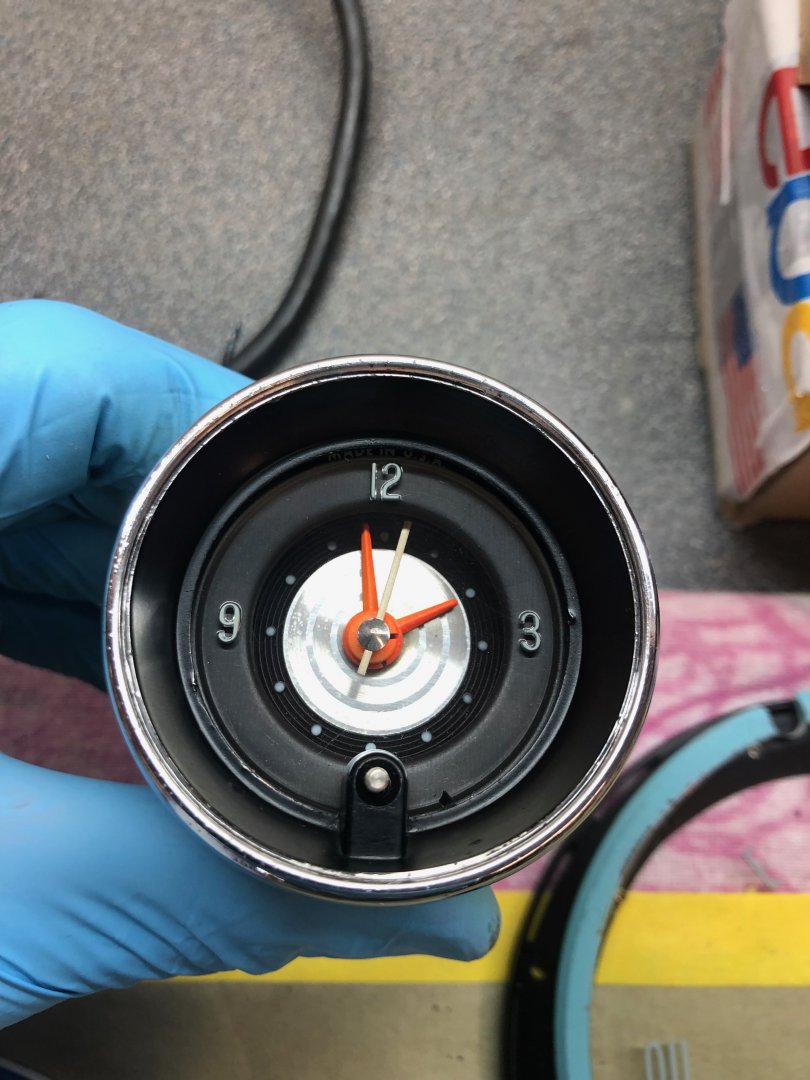

Got the clock freed up after soaking a bit in WD-40. Works like a charm! Had no idea these clocks were mechanical. They run by a spring that has a set of points on them. Every minute or so, the clock unwinds, the points close and it shoots the arm back down, rewinding the spring for another minute. So cool..... but part of what draws down the battery over long storage periods.

Polished the chrome bezel and used the SEM trim black on the inner lip.

The gauge lenses were in terrible shape after 50 years of being wiped down with a cloth. Scratched till cloudy along wit some crazing. Got out the ACA 500 with 2-inch orange pad and went to town. Came out like glass and didn't even need to go to the 520. My shot bag came in handy for holding the lens for polishing.

Restored the gauge faces with the SEM trim black as well (this time, satin). The original dots and trim were a glow in the dark paint that I couldn't find so I found an unbelievably good chrome paint pen to fill the void. Looks like real chrome plating. I was impressed!

After the rest of the pieces were polished and painted.....Viola!

Got the clock freed up after soaking a bit in WD-40. Works like a charm! Had no idea these clocks were mechanical. They run by a spring that has a set of points on them. Every minute or so, the clock unwinds, the points close and it shoots the arm back down, rewinding the spring for another minute. So cool..... but part of what draws down the battery over long storage periods.

Polished the chrome bezel and used the SEM trim black on the inner lip.

The gauge lenses were in terrible shape after 50 years of being wiped down with a cloth. Scratched till cloudy along wit some crazing. Got out the ACA 500 with 2-inch orange pad and went to town. Came out like glass and didn't even need to go to the 520. My shot bag came in handy for holding the lens for polishing.

Restored the gauge faces with the SEM trim black as well (this time, satin). The original dots and trim were a glow in the dark paint that I couldn't find so I found an unbelievably good chrome paint pen to fill the void. Looks like real chrome plating. I was impressed!

After the rest of the pieces were polished and painted.....Viola!

Last edited:

Dean Jenkins

Promoted Users

Really, really nice!

64Rivi

Promoted Users

Thank you very much, gents. Greatly appreciate the kind words.

Moving along with the leather work, the console was next. These consoles were originally painted, smooth plastic. Here's the before:

I wanted everything to look as original as possible with just the leather touch so no padding was used under the leather so it would not bulk up the surfaces. These consoles can get pretty wonky over time and the plastic gets wavy and distorted. Way too much for filler to fix without using a lot of it. I ended up using a heat gun on the waves-just enough to get the plastic pliable- and then clamped each spot between blocks of wood and let it cool. Worked great. Got most of the waves straight with the exception of a few areas I couldn't get clamps. I finished those flat with some filler and then sealed it all with epoxy.

Next up was the leather. A small section at a time so you can stretch the leather a bit and get everything flat and wrapped nice.

Some areas got really tricky. The steam iron came out and softened/ stretched the leather beautifully especially around the drivers leg vent as well as around the top of the console where it turns out and over....that was nerve racking.

And the finished product.....

After the console was the passenger side knee pad. This had the foam molded in place. After removing the original vacuum formed vinyl with a heat gun, it came off pretty clean and the foam was still in good shape. The surface had a lot of voids in it, however. I skim coated it with filler and sanded most off just to fill the surface voids and get a flat surface for the leather so it would not telegraph through.

Moving along with the leather work, the console was next. These consoles were originally painted, smooth plastic. Here's the before:

I wanted everything to look as original as possible with just the leather touch so no padding was used under the leather so it would not bulk up the surfaces. These consoles can get pretty wonky over time and the plastic gets wavy and distorted. Way too much for filler to fix without using a lot of it. I ended up using a heat gun on the waves-just enough to get the plastic pliable- and then clamped each spot between blocks of wood and let it cool. Worked great. Got most of the waves straight with the exception of a few areas I couldn't get clamps. I finished those flat with some filler and then sealed it all with epoxy.

Next up was the leather. A small section at a time so you can stretch the leather a bit and get everything flat and wrapped nice.

Some areas got really tricky. The steam iron came out and softened/ stretched the leather beautifully especially around the drivers leg vent as well as around the top of the console where it turns out and over....that was nerve racking.

And the finished product.....

After the console was the passenger side knee pad. This had the foam molded in place. After removing the original vacuum formed vinyl with a heat gun, it came off pretty clean and the foam was still in good shape. The surface had a lot of voids in it, however. I skim coated it with filler and sanded most off just to fill the surface voids and get a flat surface for the leather so it would not telegraph through.

64Rivi

Promoted Users

After that, it was a bunch of intricate filler panels for the ends of the dash and around the rear seats. Lots of heat, steam and burnt fingers in this stage.

These are the filler panels for each side of the dashboard. Believe it or not, these are the pieces I did first.....must be a glutton for punishment. LOL

Rear seat filler panels:

These were some intricate filler panels that cover the seam between the sail panels, package tray and rear seats:

And the finished products:

Then finally getting the dash dry fitted......before taking it apart all over again.

These are the filler panels for each side of the dashboard. Believe it or not, these are the pieces I did first.....must be a glutton for punishment. LOL

Rear seat filler panels:

These were some intricate filler panels that cover the seam between the sail panels, package tray and rear seats:

And the finished products:

Then finally getting the dash dry fitted......before taking it apart all over again.

slammed57

Newbie

wheww! , just read from the beginning and now 2 1/2 hours later here I am . great work! this will help me tremendously when I cut and buff,. I just sprayed black base with 6 coats of universal over the past 2 days on some small panels to dial in my gun adjustments . just want to say thanks for all the detailed document on your polishing techniques.

64Rivi

Promoted Users

Thanks very much, Slammed. Greatly appreciate the kind words and super excited that it helped.

Another shout and thank you to all the great people on this forum (as well as Barry and his crew). Everything i've done on this paint job was a direct of result of the information and expertise that you all are so willing and eager to lend. It's like a modern day apprenticeship.....just without the hands on training.....or getting yelled at by the boss for screwing something up or doing it wrong.

Yeah.....i've left all those pictures out.

Another shout and thank you to all the great people on this forum (as well as Barry and his crew). Everything i've done on this paint job was a direct of result of the information and expertise that you all are so willing and eager to lend. It's like a modern day apprenticeship.....just without the hands on training.....or getting yelled at by the boss for screwing something up or doing it wrong.

Yeah.....i've left all those pictures out.

64Rivi

Promoted Users

Life got busy......again. Daughter graduated high school, a few short weeks to enjoy summer and then we were driving her to college a few weeks ago. Trying to find some time in-between to work on the Buick but suddenly my wife wants to spend a lot of time with me.

Still plugging away though. Next up was the wood veneer for the interior. These cars came with a standard black vinyl insert up the center console with the standard interior. The optional interior came with walnut veneer in the center console along with wood veneer panels along the front and back door panels. The veneer was just plain sawn walnut with a natural finish (kind of an orange color) but -of course- I wanted something a little more special. Decided to go with quartern sawn Walnut and give it a nice dazzling finish to set off the interior.

The console starts out narrow by the back seat and widens as it goes up to the dash pad. I book matched the veneer to match the shape of the center console so the quarter sawn grain spreads open a bit as it goes up the console. It's subtle....but every detail counts!

Quarter sawn walnut has a nice grain although nothing too spectacular in terms of finish. I wanted to give the wood some chatoyance so the grain would pop and dance a bit as you viewed it from different angles. I started off with an alcohol dye stain so the grain would not get muddle with the pigments in a regular stain. After that was several coats of varnish. I applied the varnish while sanding with fine grit paper to create a swarf to help fill the pores like a natural grain filler (I didn't want to use grain filler as most have pigments and it makes the pores stand out). After several coats, I let it sit for a week to fully dry.

It looks dark and muddy but stick with me....it gets better.

At the same time, I had to create all of the patterns for the console and the door panels. Also re-shot all of the black borders on the door panel inserts with SEM Trim Black

At this stage, I cut out all of the patterns. This was before clearing so the edges would be completely coated when finished.....and so I didn't mess the finish up while cutting them out.

After that, hit everything with three wet coats of UV clear.

You can see the the pores are still open a bit. That was the point of the three wet coats; to help fill them a bit more. I then wet sanded all of the veneers with 800 wet to flatten the surface and hit them all again with 3-more medium wet coats.

Now you can see the Chatoyance with different angles! Looks MUCH better in natural/ sun light.

Still plugging away though. Next up was the wood veneer for the interior. These cars came with a standard black vinyl insert up the center console with the standard interior. The optional interior came with walnut veneer in the center console along with wood veneer panels along the front and back door panels. The veneer was just plain sawn walnut with a natural finish (kind of an orange color) but -of course- I wanted something a little more special. Decided to go with quartern sawn Walnut and give it a nice dazzling finish to set off the interior.

The console starts out narrow by the back seat and widens as it goes up to the dash pad. I book matched the veneer to match the shape of the center console so the quarter sawn grain spreads open a bit as it goes up the console. It's subtle....but every detail counts!

Quarter sawn walnut has a nice grain although nothing too spectacular in terms of finish. I wanted to give the wood some chatoyance so the grain would pop and dance a bit as you viewed it from different angles. I started off with an alcohol dye stain so the grain would not get muddle with the pigments in a regular stain. After that was several coats of varnish. I applied the varnish while sanding with fine grit paper to create a swarf to help fill the pores like a natural grain filler (I didn't want to use grain filler as most have pigments and it makes the pores stand out). After several coats, I let it sit for a week to fully dry.

It looks dark and muddy but stick with me....it gets better.

At the same time, I had to create all of the patterns for the console and the door panels. Also re-shot all of the black borders on the door panel inserts with SEM Trim Black

At this stage, I cut out all of the patterns. This was before clearing so the edges would be completely coated when finished.....and so I didn't mess the finish up while cutting them out.

After that, hit everything with three wet coats of UV clear.

You can see the the pores are still open a bit. That was the point of the three wet coats; to help fill them a bit more. I then wet sanded all of the veneers with 800 wet to flatten the surface and hit them all again with 3-more medium wet coats.

Now you can see the Chatoyance with different angles! Looks MUCH better in natural/ sun light.

64Rivi

Promoted Users

Almost done......

Hit everything with pink assilx on a foam pad just to knock the surface down and get the trash flat. Polished the veneer with an orange pad and ACA 500 followed by a black pad with ACA 520.

Now you can get a good look at the color in the sunlight. The fluorescent lights don't do it justice!

And then back in the console along with the door panel inserts. The "R" Riviera badge is a nice finishing touch on these panels!

Hit everything with pink assilx on a foam pad just to knock the surface down and get the trash flat. Polished the veneer with an orange pad and ACA 500 followed by a black pad with ACA 520.

Now you can get a good look at the color in the sunlight. The fluorescent lights don't do it justice!

And then back in the console along with the door panel inserts. The "R" Riviera badge is a nice finishing touch on these panels!

You captured my attention last night going thru your Epic novel.

Don't know what your profession is or missed that but you have rare talents few possess.

I was impressed with the paint and body work and then you pull out the Leather..........

This car will be a Show Stopper and Winner and if you don't enter It in the Top Shows,

It will be your Biggest mistake you ever make.

I'm sure Barry can direct you with such.

Elegantly Exquisite Sir.

Don't know what your profession is or missed that but you have rare talents few possess.

I was impressed with the paint and body work and then you pull out the Leather..........

This car will be a Show Stopper and Winner and if you don't enter It in the Top Shows,

It will be your Biggest mistake you ever make.

I'm sure Barry can direct you with such.

Elegantly Exquisite Sir.

64Rivi

Promoted Users

Whoa!

Gents; can't tell you how humbling those compliments are! Greatly appreciated, to say the least! I've been enjoying this journey and happy to see all the hard work pay off after all these years. Hoping to actually get to driver it in the near future. In the meantime, I just keep plugging away as time permits and enjoy the ride

Mike: Jack of all trades.....master of none. I'm actually in sales but have spent a lifetime working with my hands and working on cars since I was kid. Truth is; if there are tools involved: I'm in. (although taping and spackling sheetrock is like my kyrptonite!)

I'm actually in sales but have spent a lifetime working with my hands and working on cars since I was kid. Truth is; if there are tools involved: I'm in. (although taping and spackling sheetrock is like my kyrptonite!)

Hopefully I'll have more to share soon. I've been plugging away on the door panels and upholstery.

Thanks again for the kind words!!!!

Gents; can't tell you how humbling those compliments are! Greatly appreciated, to say the least! I've been enjoying this journey and happy to see all the hard work pay off after all these years. Hoping to actually get to driver it in the near future. In the meantime, I just keep plugging away as time permits and enjoy the ride

Mike: Jack of all trades.....master of none.

Hopefully I'll have more to share soon. I've been plugging away on the door panels and upholstery.

Thanks again for the kind words!!!!