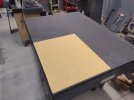

I had made a post about this previously, but there was an issue with the previous thread so here we go again. I had been looking for a rust free box for my 2001 GMC Sierra. My buddy came across a parts truck with a 1 year only composite box. Only problem is the previous owner cut a hole in the bed floor to replace a fuel pump. There's another hole in the back they cut to weld a jump seat to the frame.

Chris Hamilton posted a video of SEM showing how to do a patch on SMC with a 2 component panel bond product. This number was discontinued, I called SEM's tech line and got the new part #40887. I made a plaster cast of the driver's side front, hopefully I can use this to replicate the missing section at passenger rear. I attached some pictures to show what I have going on.

Chris Hamilton posted a video of SEM showing how to do a patch on SMC with a 2 component panel bond product. This number was discontinued, I called SEM's tech line and got the new part #40887. I made a plaster cast of the driver's side front, hopefully I can use this to replicate the missing section at passenger rear. I attached some pictures to show what I have going on.