B

bomccorkle

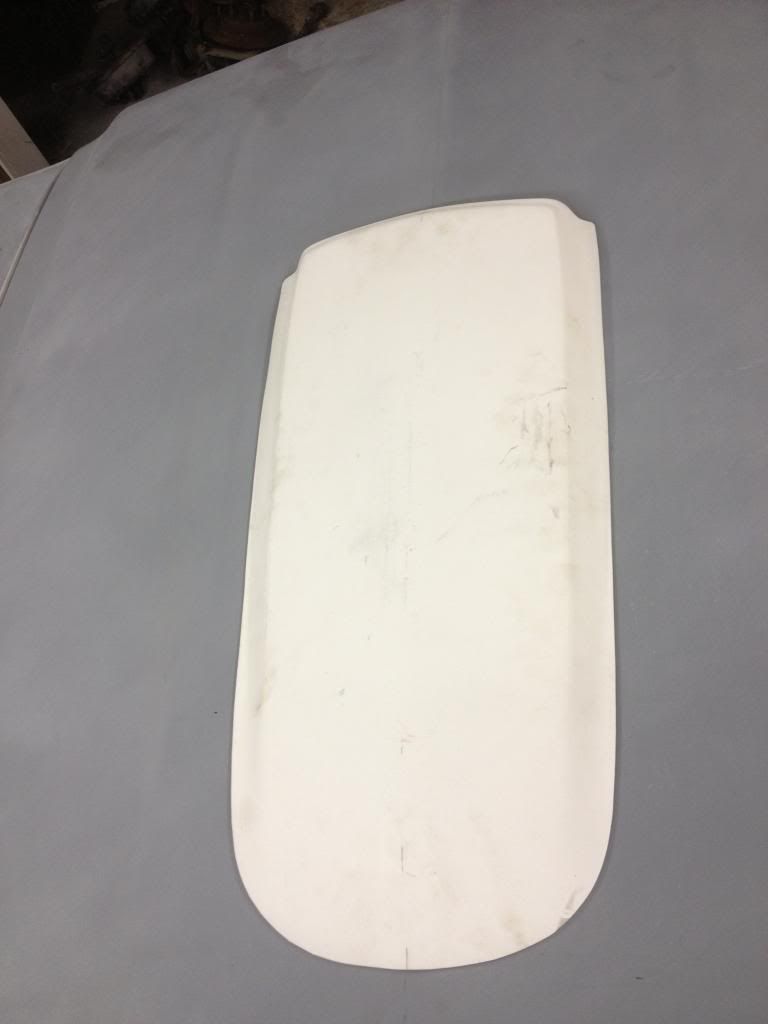

I have a 69 mustang and have been toying with the idea of adding a hood scoop. I have a steel hood in good shape and would like to, if at all possible, bond a scoop on. I have read around and around on the other forums of guys doing it and having cracking issues and then again guys doing it the exact same way and having no issues. I guess my question is can I reliably bond a scoop on? Fiberglass and pot metal are all that's really available(and my metalworking skills aren't up to the task of cabbing one up and welding it on) I did bond on some brake scoops about a year ago and they've held up well but then again I'd assume in the dead of winter the hood would see somewhere between 120-140 degrees to a maybe minus 10 in these parts.

TIA

Bo

TIA

Bo