C

cstrom72

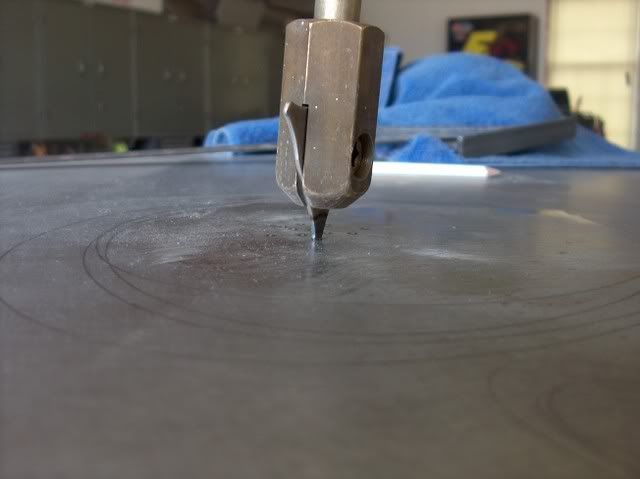

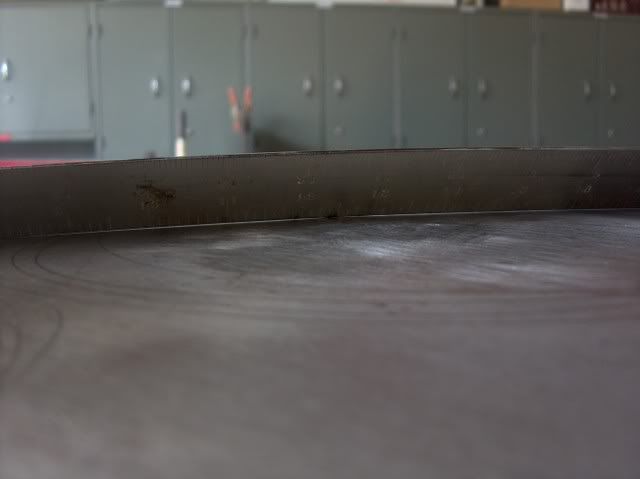

I'm having a hell of a time with this dent on the hood of my 68 Mustang. It's right on the edge of the under bracing so I can't get to part of it. I've tried hammer off and hammer on dolly. Just can't seem to get it. Any tips? I think it's getting work hardened...