Raymond_B

Hobbyist

I figure you guys are the best to ask

I have some small block Ford sheetmetal valve covers. The engine is going to run 8 coils, Fords do not use any type of valve cover mounted coils. So I was going to find someone to TIG some threaded standoffs to the VCs. But I am having problems finding anyone in my area. So I had a thought, why not just use some sort of epoxy or bonding agent to adhere the standoffs to the VCs. Would you guys recommend something like a panel bond product? And if so are there any small quantity setups that do not need a gun?

I was going to paint the valve covers with black epoxy, but should I wait and bond the standoffs then paint or paint them before and then again when the standoffs are on? I wasn't sure if the panel bond or epoxy would behave differently than a body filler.

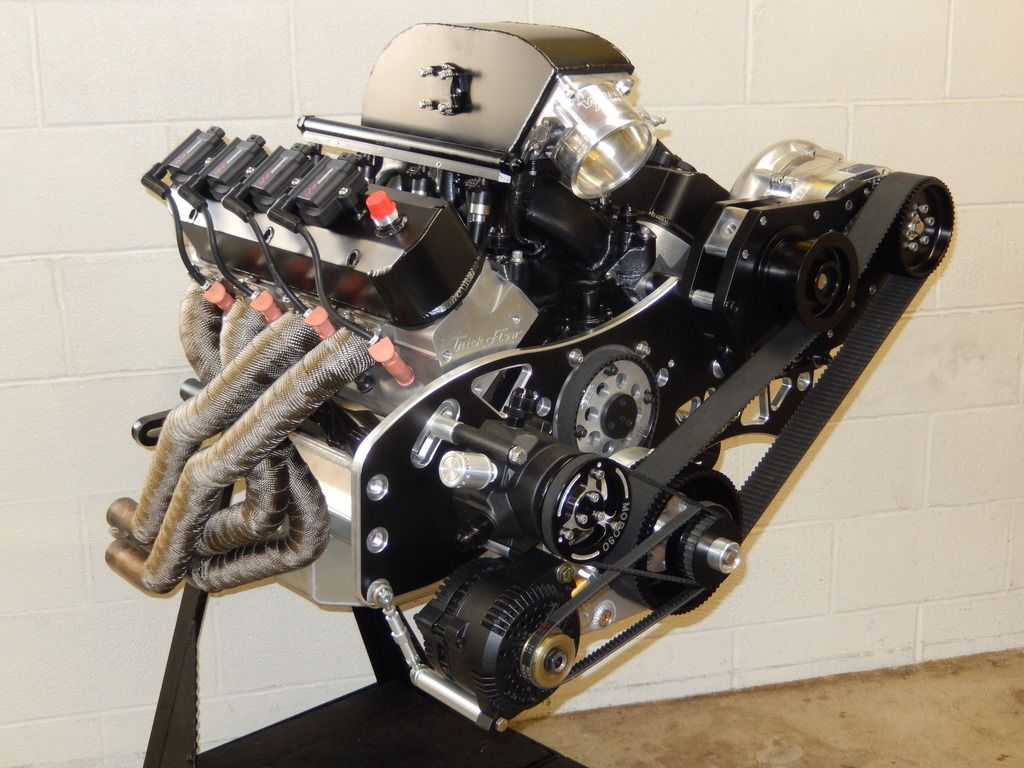

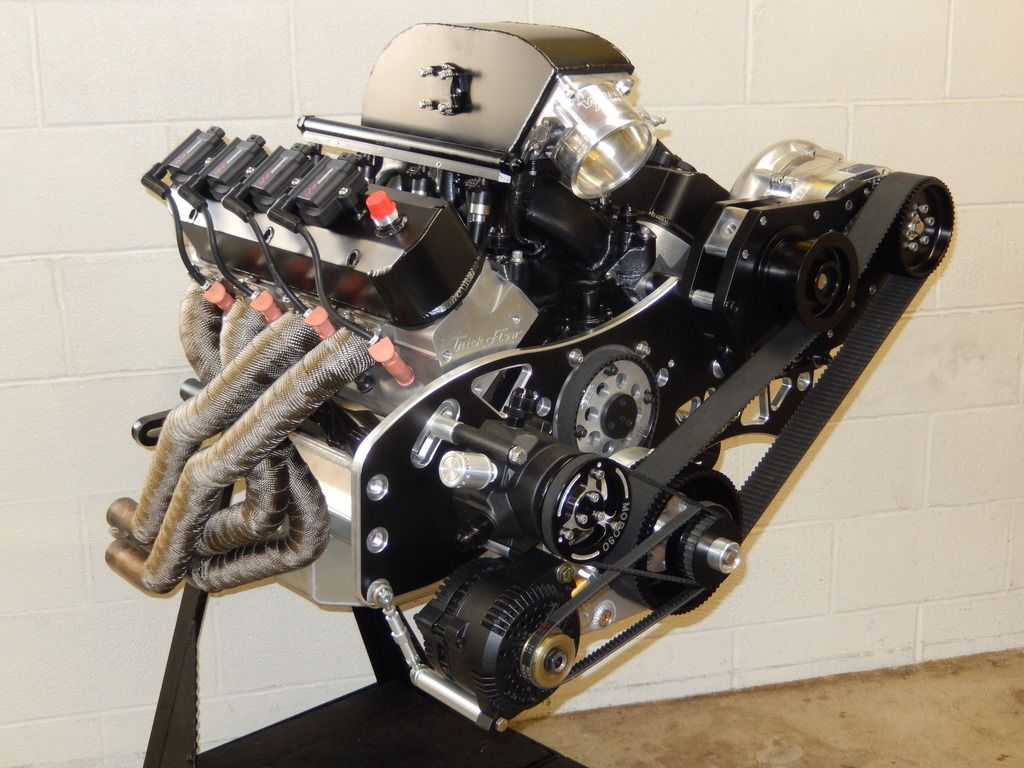

For reference here is a small block Ford with valve cover mounted coils and is exactly what I am looking to do.

I have some small block Ford sheetmetal valve covers. The engine is going to run 8 coils, Fords do not use any type of valve cover mounted coils. So I was going to find someone to TIG some threaded standoffs to the VCs. But I am having problems finding anyone in my area. So I had a thought, why not just use some sort of epoxy or bonding agent to adhere the standoffs to the VCs. Would you guys recommend something like a panel bond product? And if so are there any small quantity setups that do not need a gun?

I was going to paint the valve covers with black epoxy, but should I wait and bond the standoffs then paint or paint them before and then again when the standoffs are on? I wasn't sure if the panel bond or epoxy would behave differently than a body filler.

For reference here is a small block Ford with valve cover mounted coils and is exactly what I am looking to do.