MP&C

Member

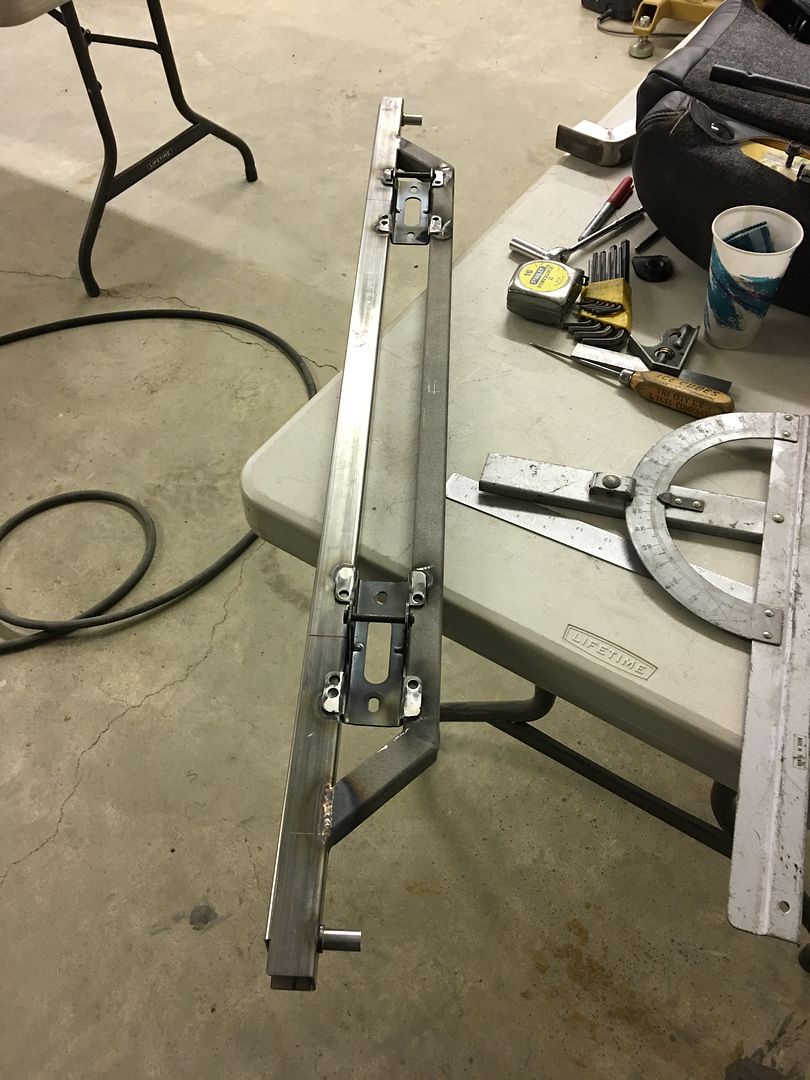

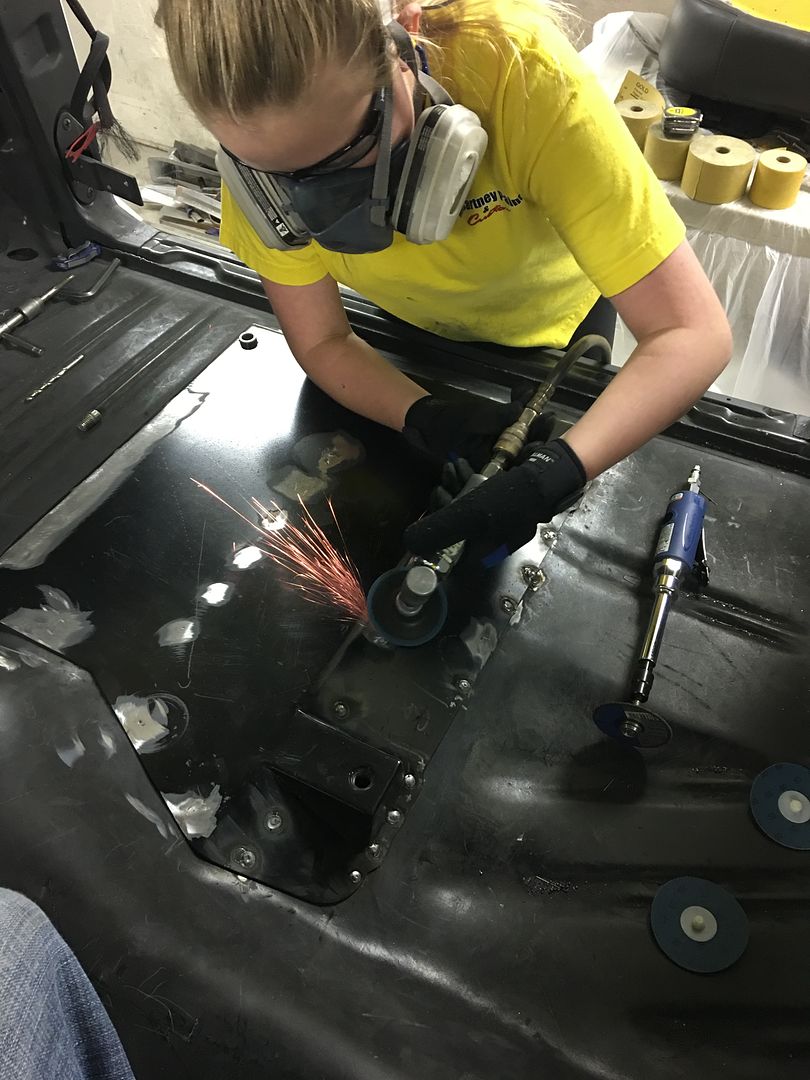

Getting some seat brackets welded in...

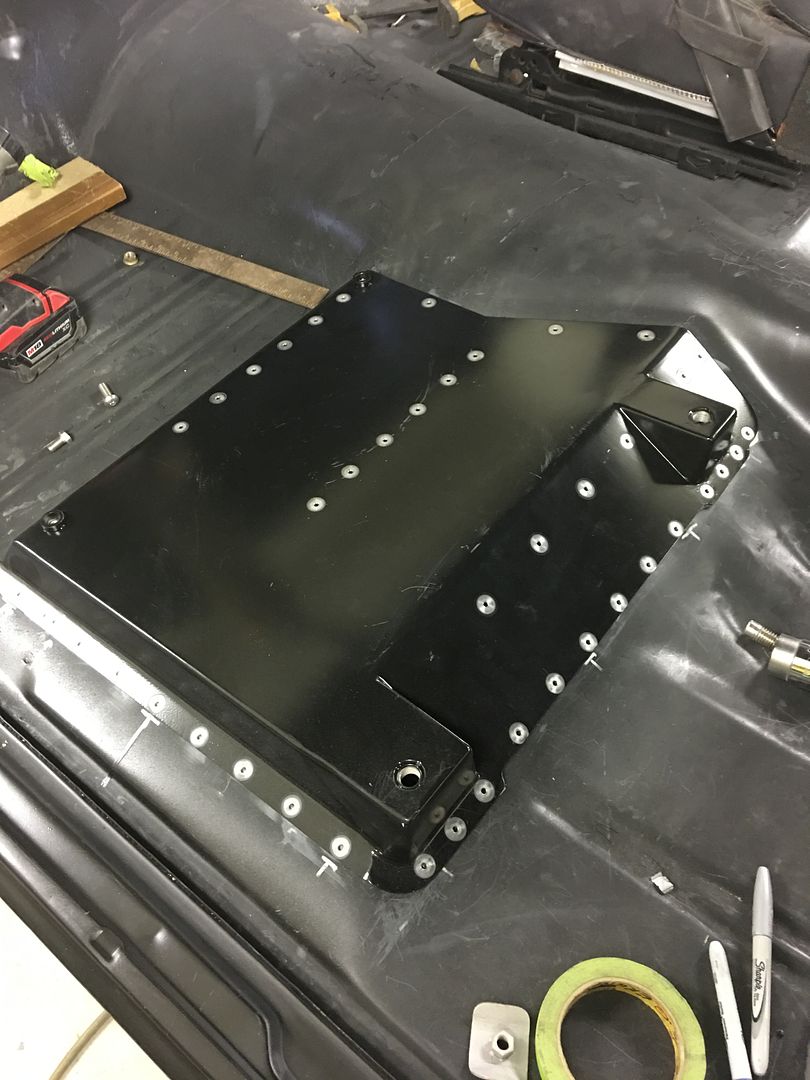

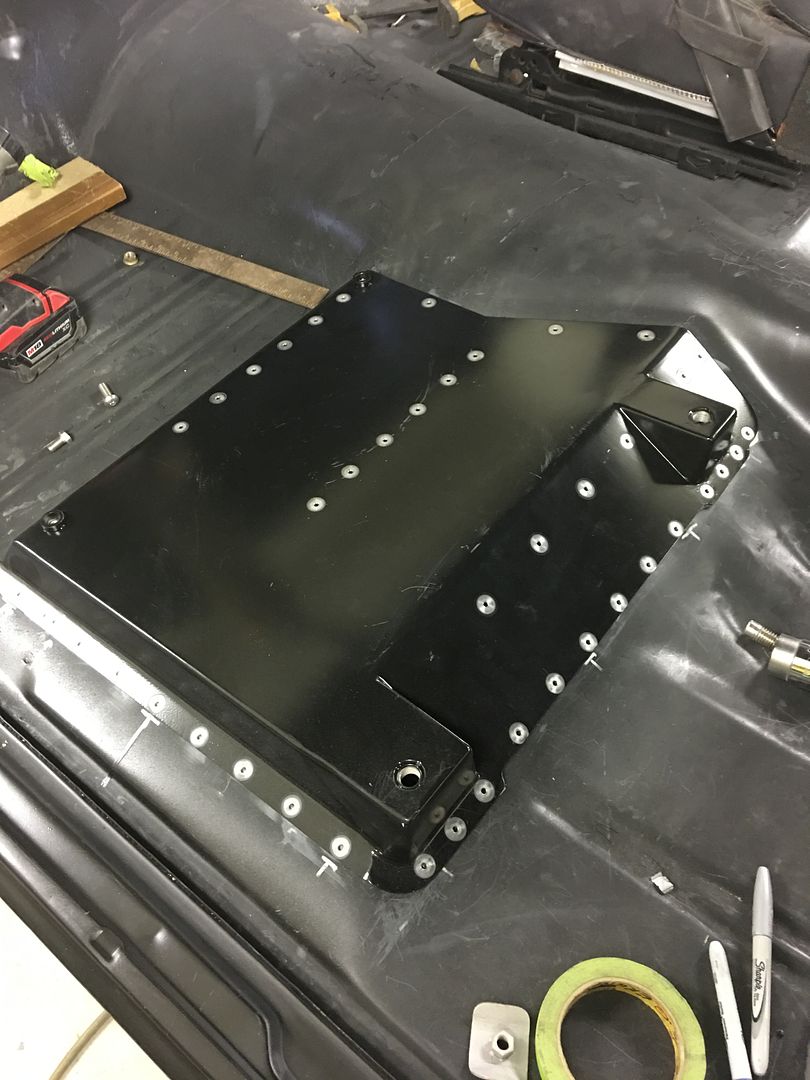

Plug welding...

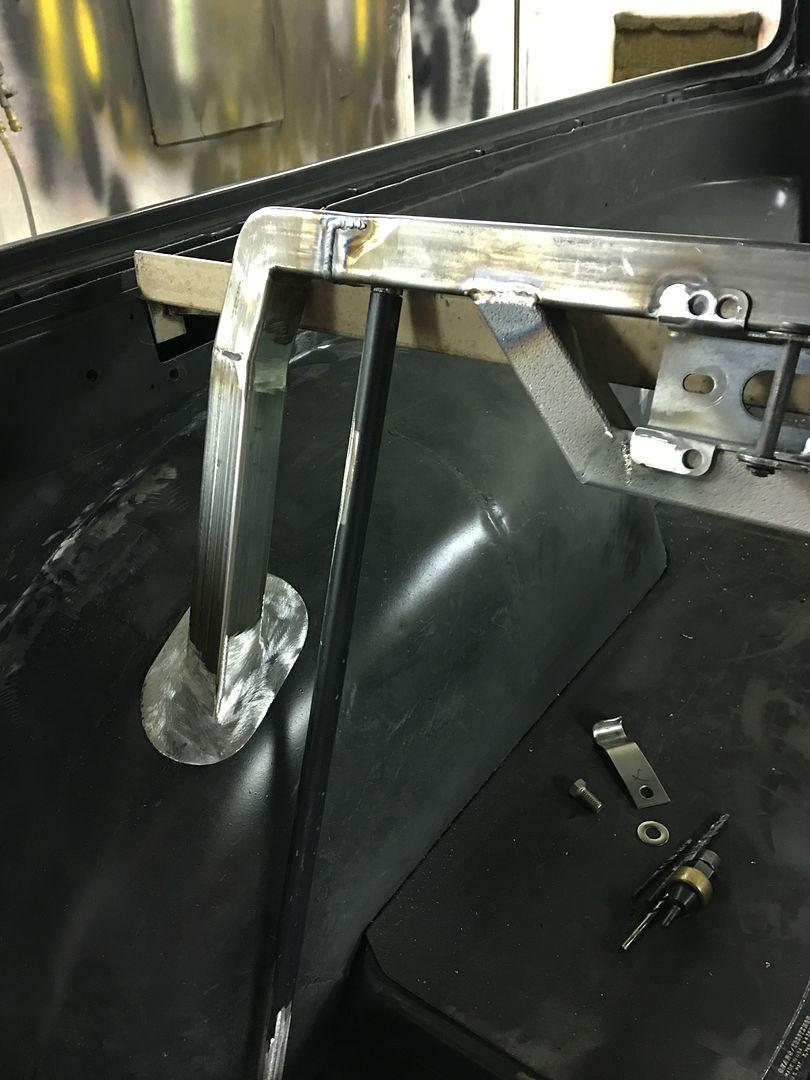

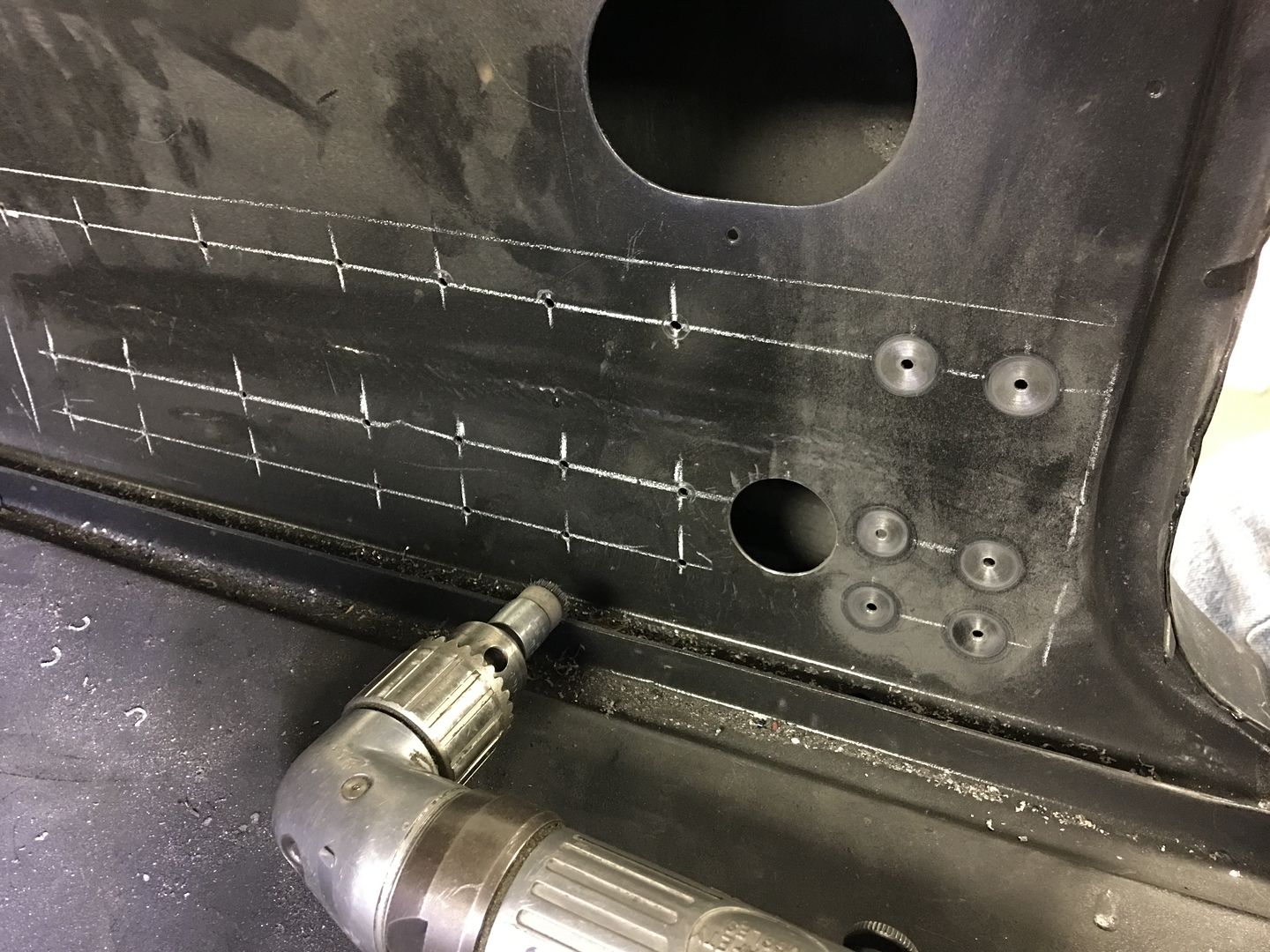

But before we get all the front seats in and make it harder to access the back, lets get the seat riser plug welded in for the back seat...

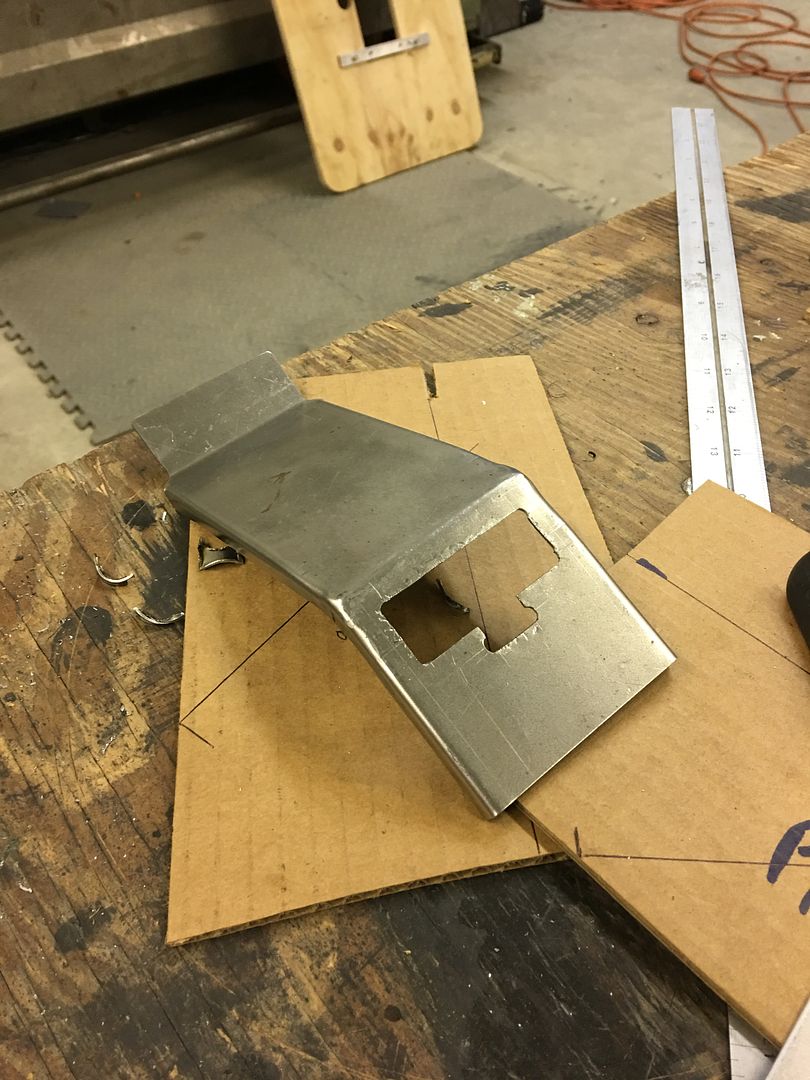

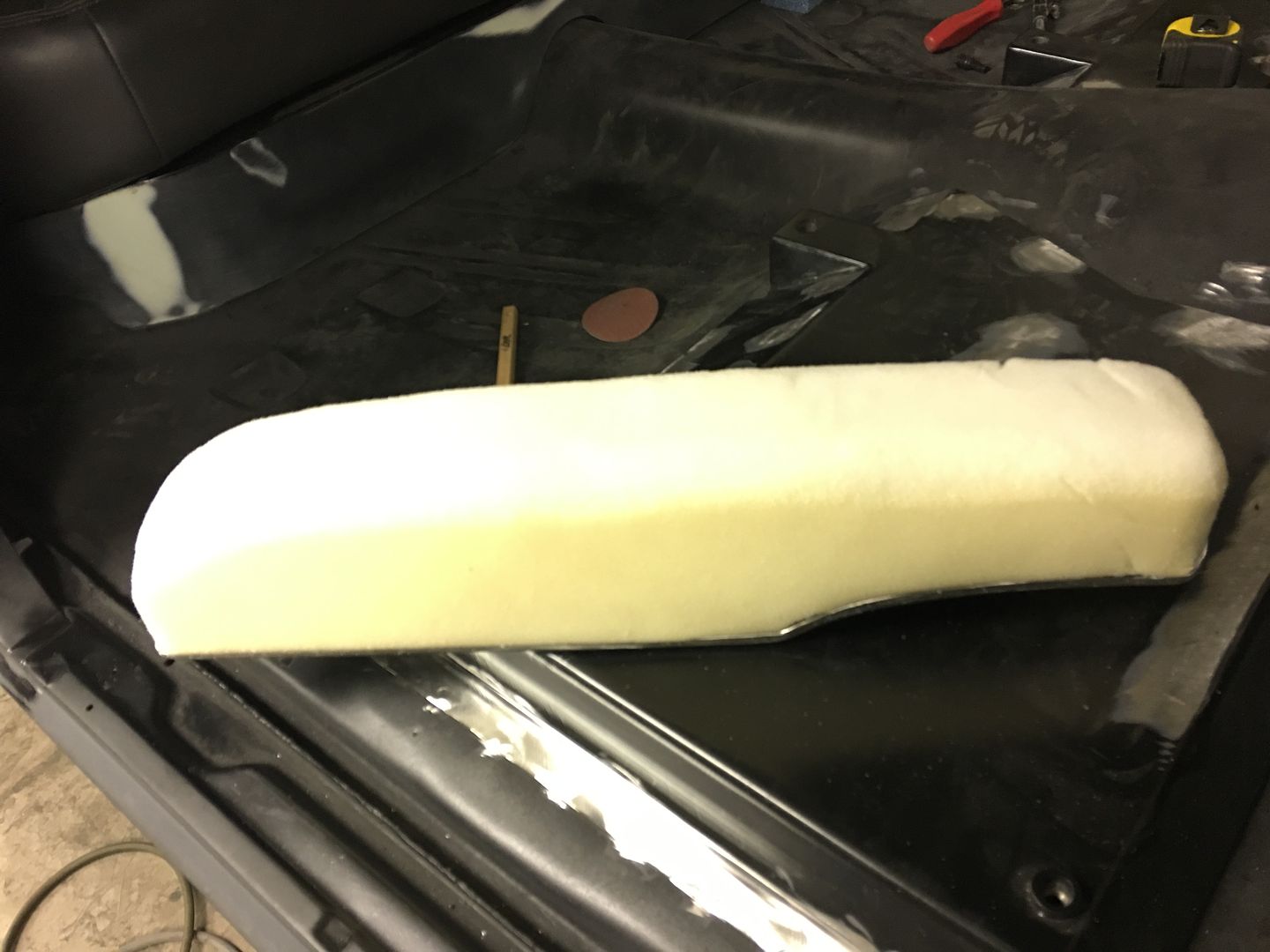

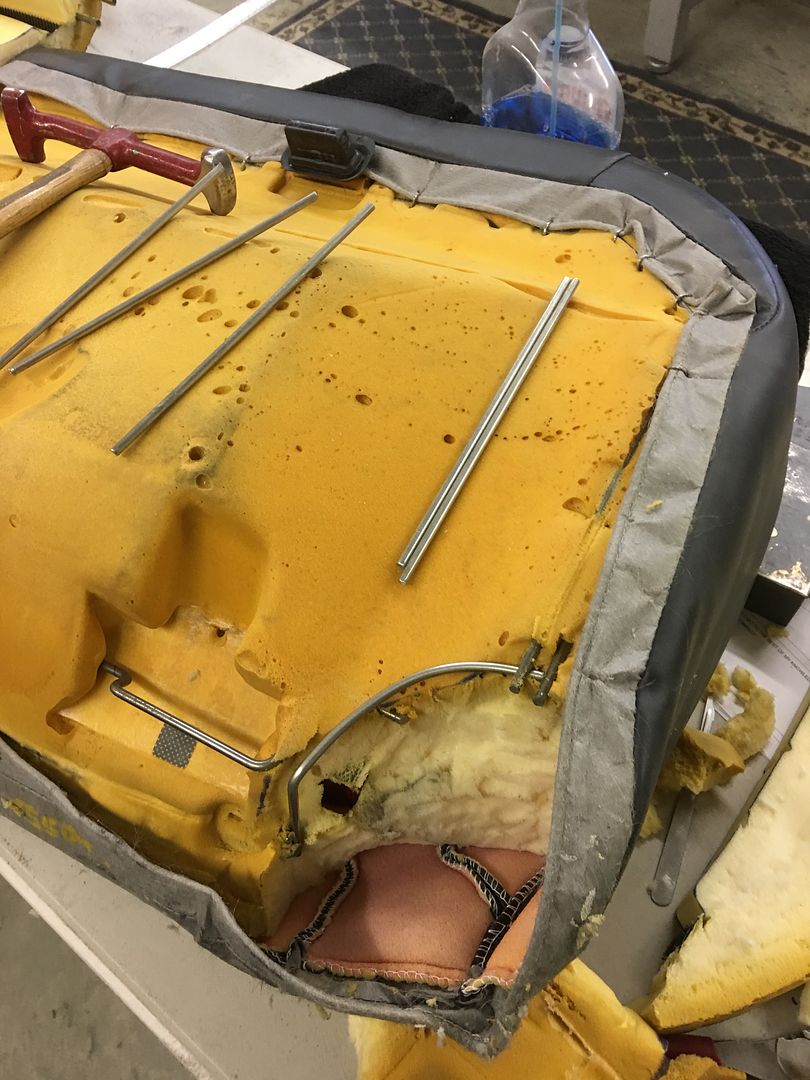

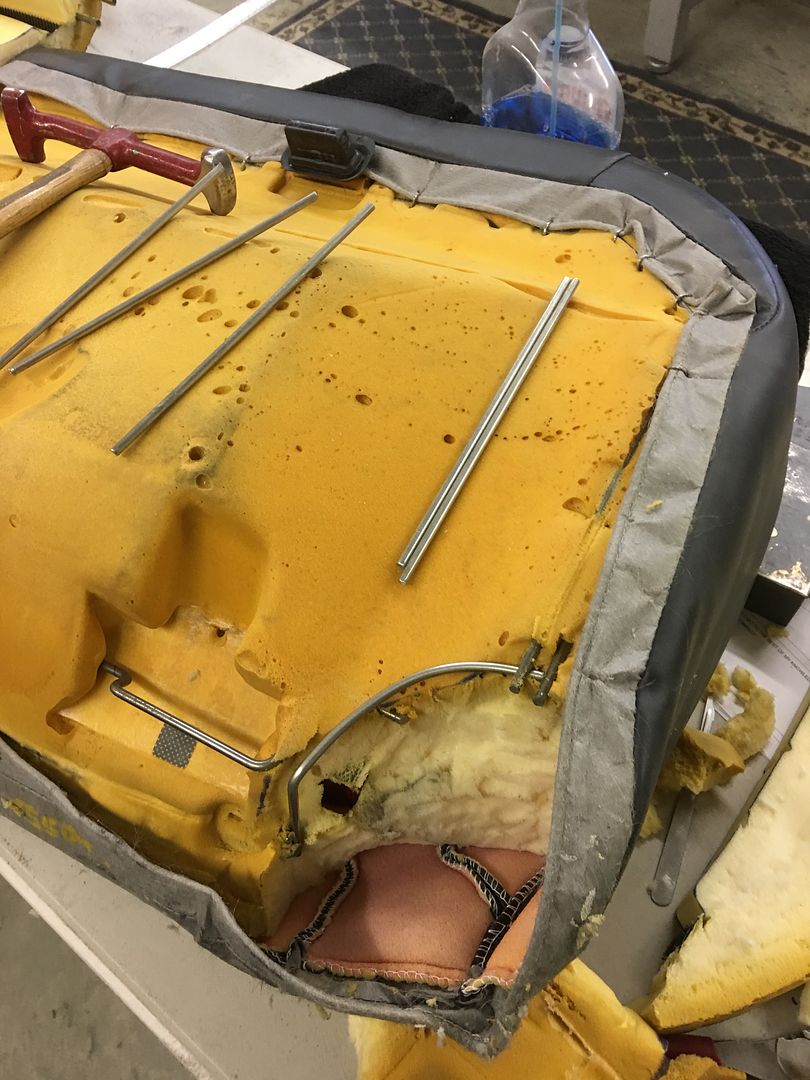

Next, our rear seat that came with the buckets was slightly oversize for our widened wheel wells. Some quick measurements showed we need to lose about 2" in width..

Then the rear corners needed relieving for the wheel tubs.....

Some 3/16 diameter stainless rod was used to reconnect the pieces in the new rear corners

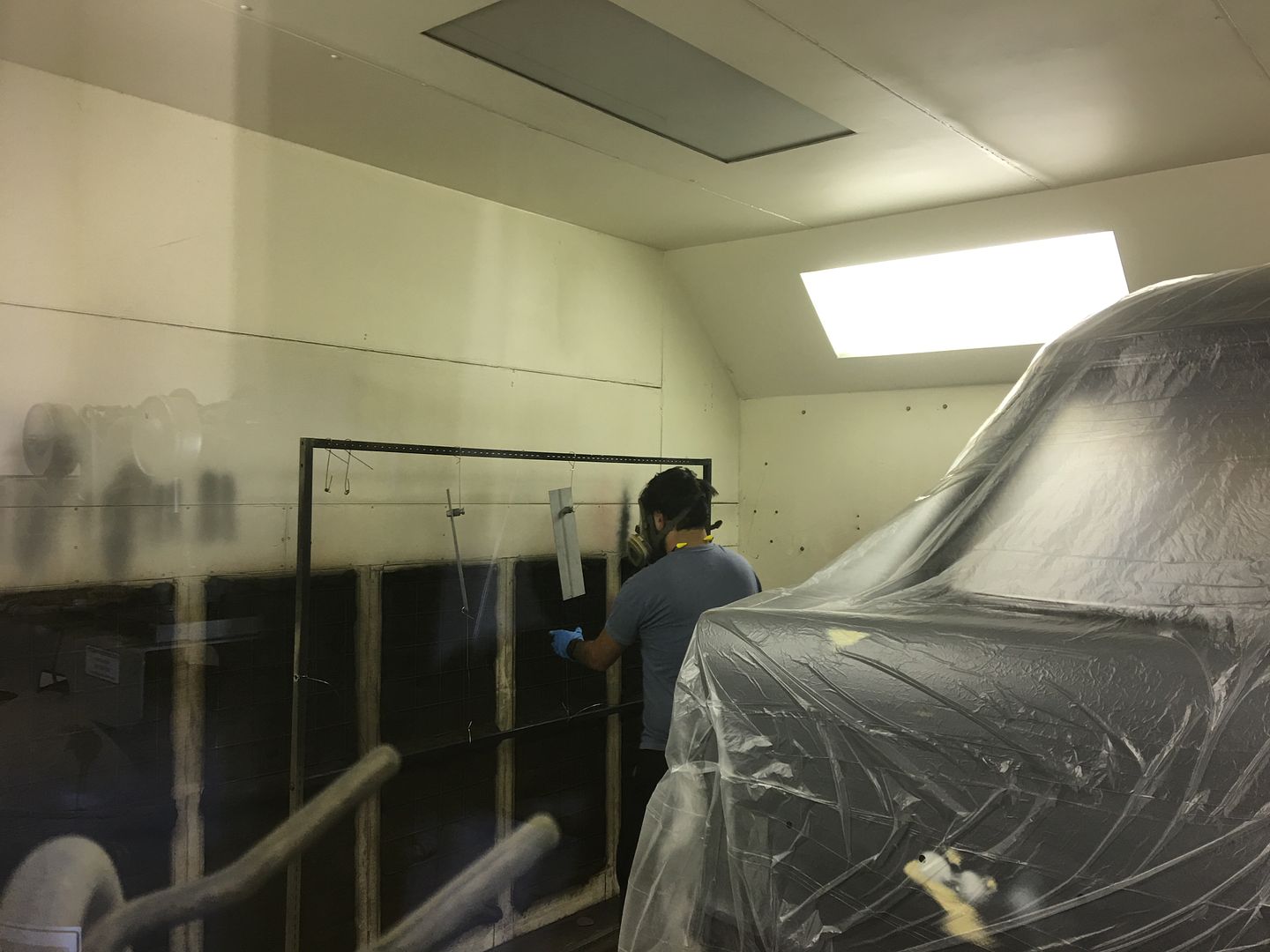

Some fire prevention for the foam..

With both sides fitting individually, time to join our sides back together...

Video of the surgery results....

With the overlap of material trimmed, this part is looking pretty good!

Plug welding...

But before we get all the front seats in and make it harder to access the back, lets get the seat riser plug welded in for the back seat...

Next, our rear seat that came with the buckets was slightly oversize for our widened wheel wells. Some quick measurements showed we need to lose about 2" in width..

Then the rear corners needed relieving for the wheel tubs.....

Some 3/16 diameter stainless rod was used to reconnect the pieces in the new rear corners

Some fire prevention for the foam..

With both sides fitting individually, time to join our sides back together...

Video of the surgery results....

With the overlap of material trimmed, this part is looking pretty good!