MJM

Promoted Users

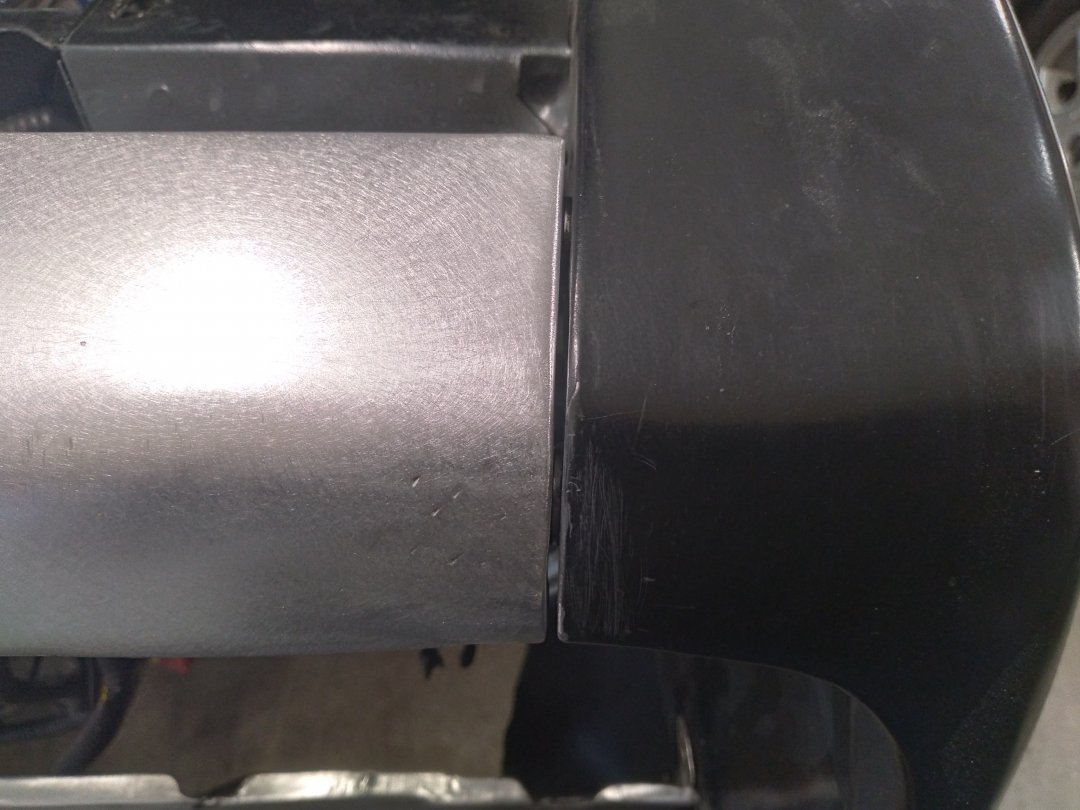

Worked on the header panel the meets the drivers side fender. Straightened both pieces so they are flush if butted up against each other.

My question is, do all body panels have gaps, or can they be butted against each other? I have no idea how this came from the factory.

I took a picture of the before on the drivers side but, the picture is to dark to see clearly so, the first picture is the passanger side, metal to metal

Metal to metal

Drivers side with 1/16 gap.

My question is, do all body panels have gaps, or can they be butted against each other? I have no idea how this came from the factory.

I took a picture of the before on the drivers side but, the picture is to dark to see clearly so, the first picture is the passanger side, metal to metal

Metal to metal

Drivers side with 1/16 gap.