MP&C

Member

Got a new addition to the shop, this Meco came from TM Technologies, or TinManTech. I got it hooked up last night and ran a couple passes.

Let me start by saying I am not a gas welder. I have a Henrob torch that I have found awkward to use, likely the operator, so I have always used either MIG or TIG. This video shows my second attempt with the Meco, the first attempt I did not have sufficient heat as I was worried about blowing holes. The two “scraps” were picked off the floor and tacked together about every 3/4”, then fusion welded the distance shown, yielding a full penetration weld with nice HAZ conisistency. Very impressed with the light weight and ease of use, even for an old dog learning new tricks. Video shows in order: front, back, planished, and bent at 90* for our destruction test.

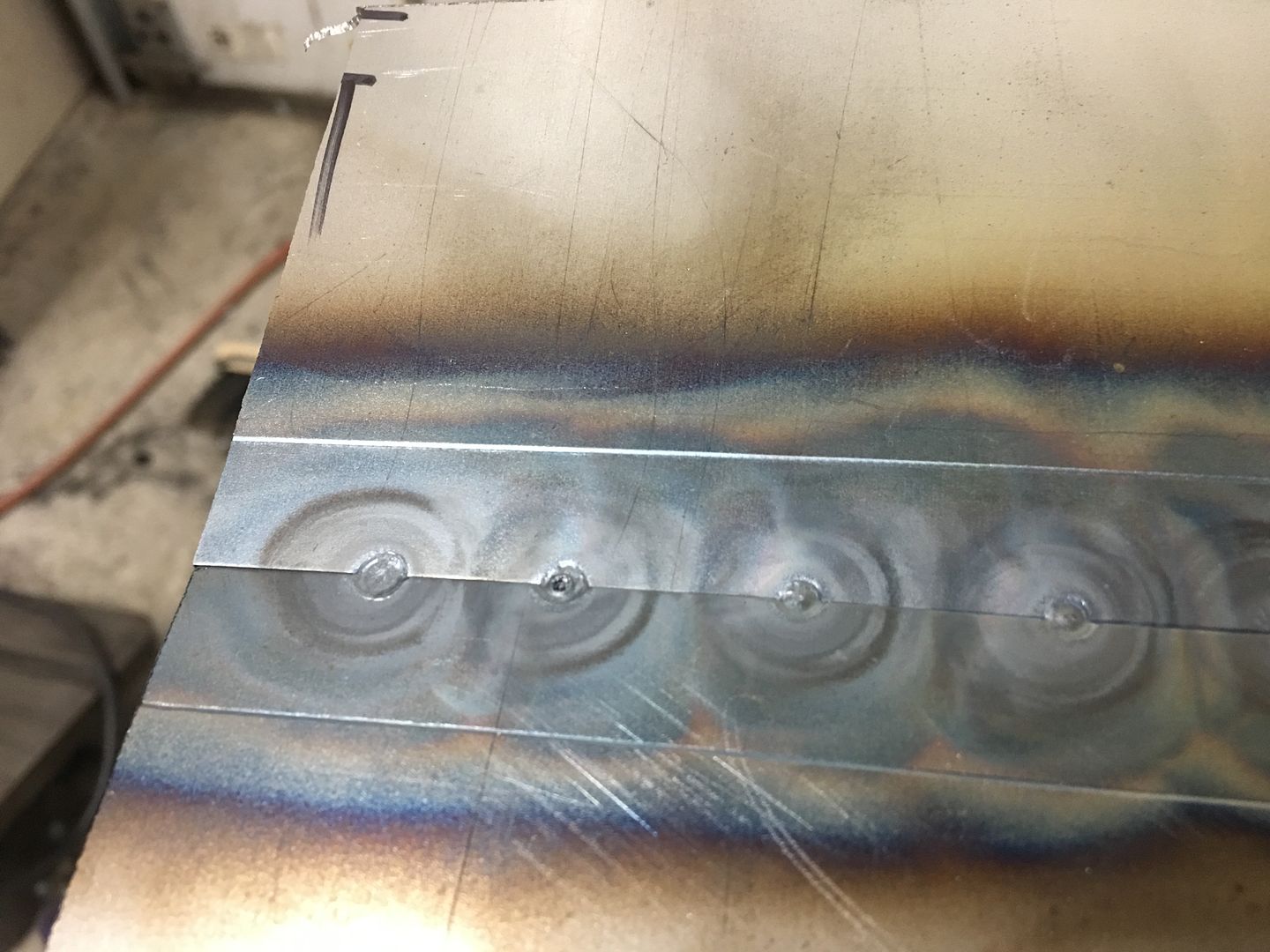

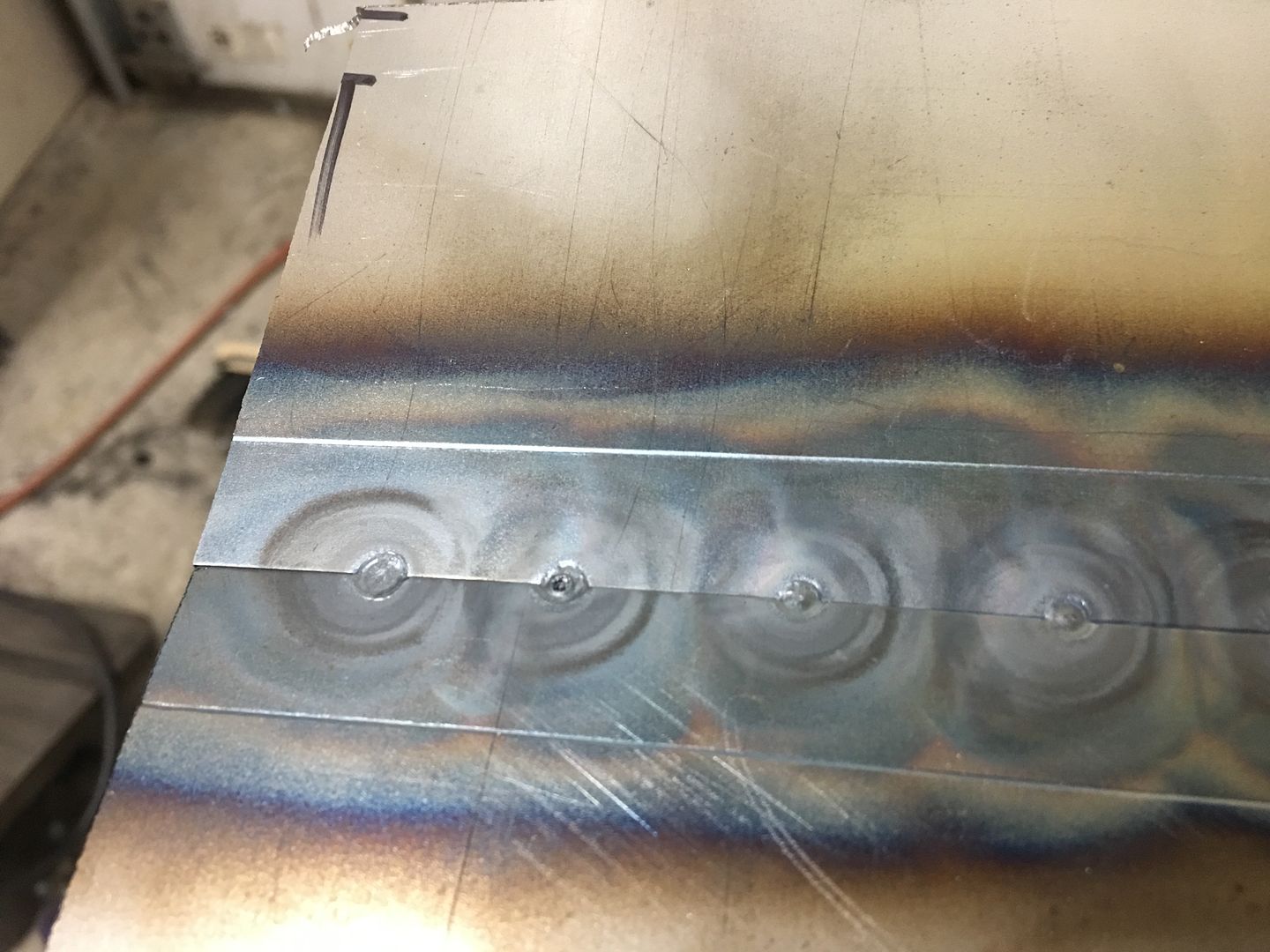

Tacks, front side..

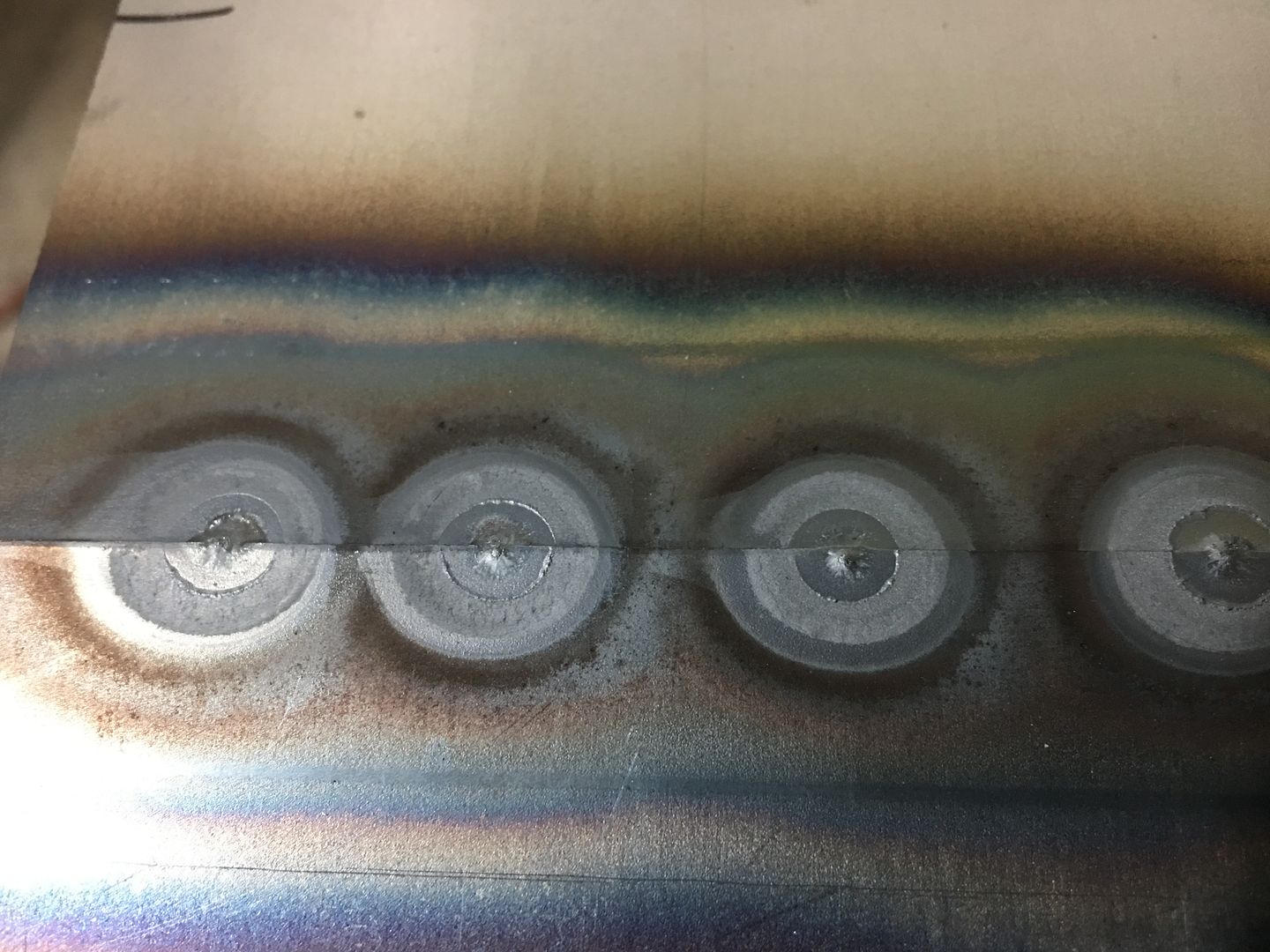

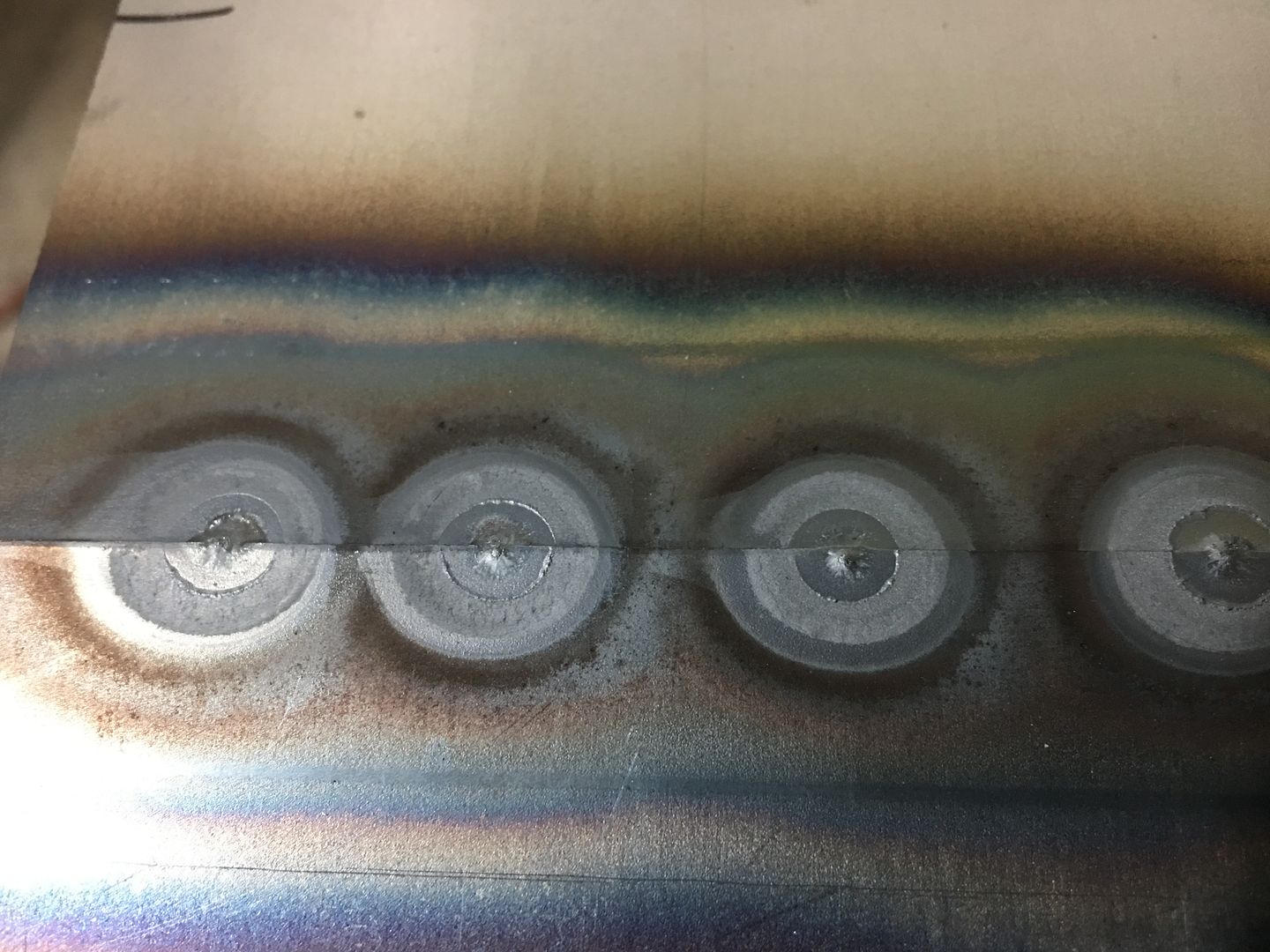

Rear side, full penetration...

Full pass with full weld penetration, bent 90* for destruction test.. Line shown is mark left by press brake die....

Rear side held up well

Very impressed with this torch, one handed valve adjustments are a breeze, light weight and easy to use..

Let me start by saying I am not a gas welder. I have a Henrob torch that I have found awkward to use, likely the operator, so I have always used either MIG or TIG. This video shows my second attempt with the Meco, the first attempt I did not have sufficient heat as I was worried about blowing holes. The two “scraps” were picked off the floor and tacked together about every 3/4”, then fusion welded the distance shown, yielding a full penetration weld with nice HAZ conisistency. Very impressed with the light weight and ease of use, even for an old dog learning new tricks. Video shows in order: front, back, planished, and bent at 90* for our destruction test.

Tacks, front side..

Rear side, full penetration...

Full pass with full weld penetration, bent 90* for destruction test.. Line shown is mark left by press brake die....

Rear side held up well

Very impressed with this torch, one handed valve adjustments are a breeze, light weight and easy to use..