MDPotter

Promoted Users

I'm a hobbyist at best when it comes to bodywork so I'm always making some kind of mistake. I was all geared up to paint fenders and doors this weekend but ran into some issues. I lost concentration for a split second and double coated a spot on a fender and resulted in runs in the sealer and I also discovered a couple pinholes. I put the fenders aside after sealing. No big deal, just have to take care of those two issues and resand and start over with the sealer.

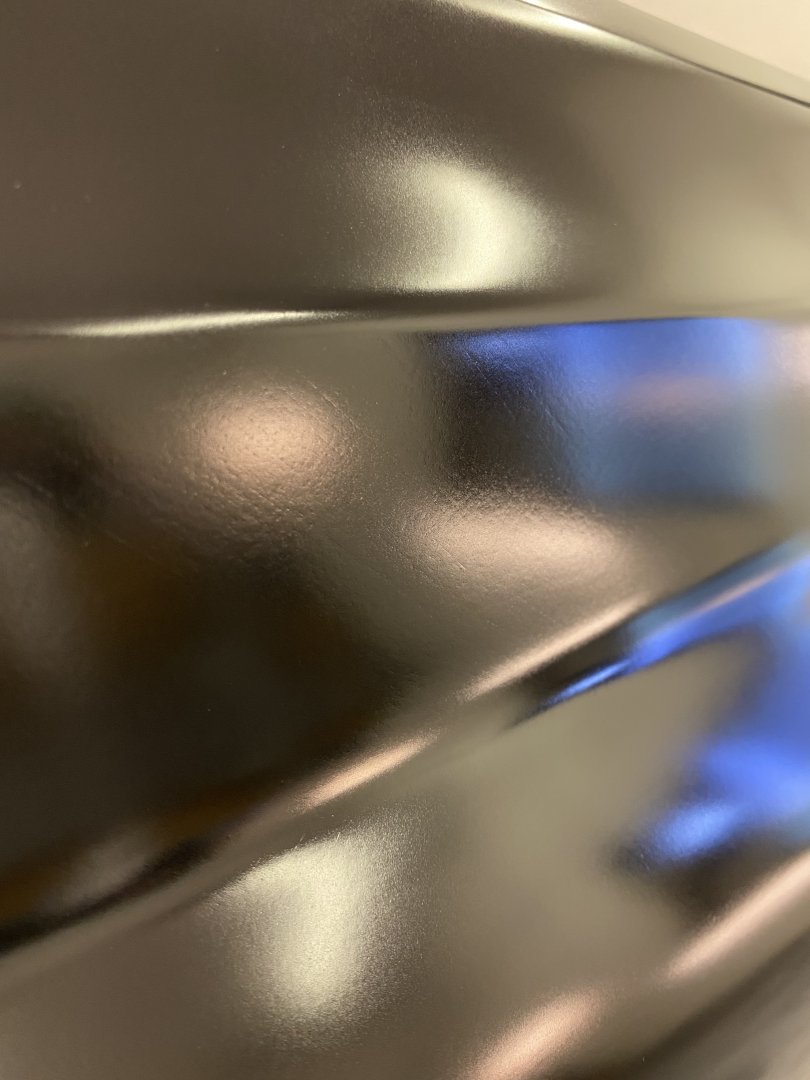

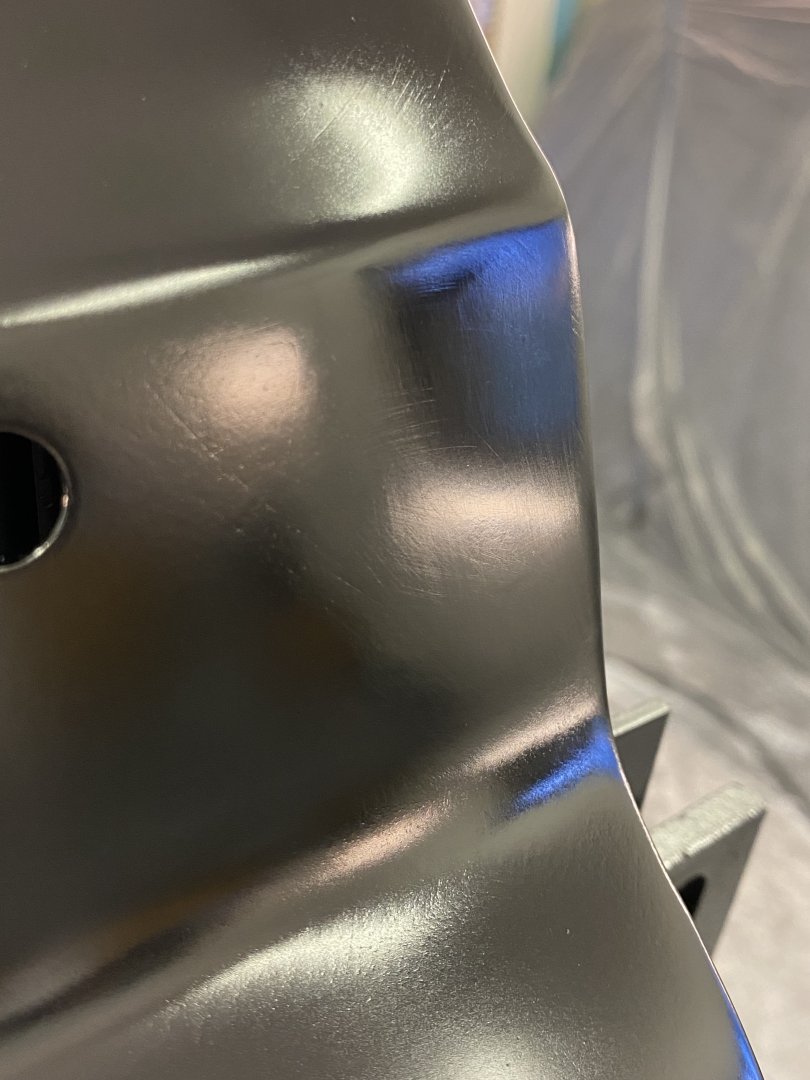

What I'm not entirely sure how to fix is the issues in the basecoat on the doors. This is my first project using SPI basecoat so I'm still learning how to spray it and ended up with a few runs in one spot. The other issues are sand scratches. After I sprayed sealer, I saw some deep scratches in a couple spots so I wet sanded with 600 and sprayed the base but they're showing through. Also seeing some deep scratches in other spots. So my question is - can I sand these spots with 600 and reapply base over the entire area or do I need to reseal it and then base? I have grey 2K underneath the black sealer and it's going to be a couple weeks before I can get to it.

Runs in base

Deep sand scratches from 2K blocking

Sand scratches from sanding the sealer

What I'm not entirely sure how to fix is the issues in the basecoat on the doors. This is my first project using SPI basecoat so I'm still learning how to spray it and ended up with a few runs in one spot. The other issues are sand scratches. After I sprayed sealer, I saw some deep scratches in a couple spots so I wet sanded with 600 and sprayed the base but they're showing through. Also seeing some deep scratches in other spots. So my question is - can I sand these spots with 600 and reapply base over the entire area or do I need to reseal it and then base? I have grey 2K underneath the black sealer and it's going to be a couple weeks before I can get to it.

Runs in base

Deep sand scratches from 2K blocking

Sand scratches from sanding the sealer