You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Drilling & tap lube

- Thread starter EddieF

- Start date

Cool Tool

It works great, but smells bad and wont pour in cold temps.

https://www.amazon.com/1-Pint-Cool-Cutting-Tapping-Fluid/dp/B002R692GS

It works great, but smells bad and wont pour in cold temps.

https://www.amazon.com/1-Pint-Cool-Cutting-Tapping-Fluid/dp/B002R692GS

EddieF

Top Banana

Thanks again. Sure are many varients out there i see.

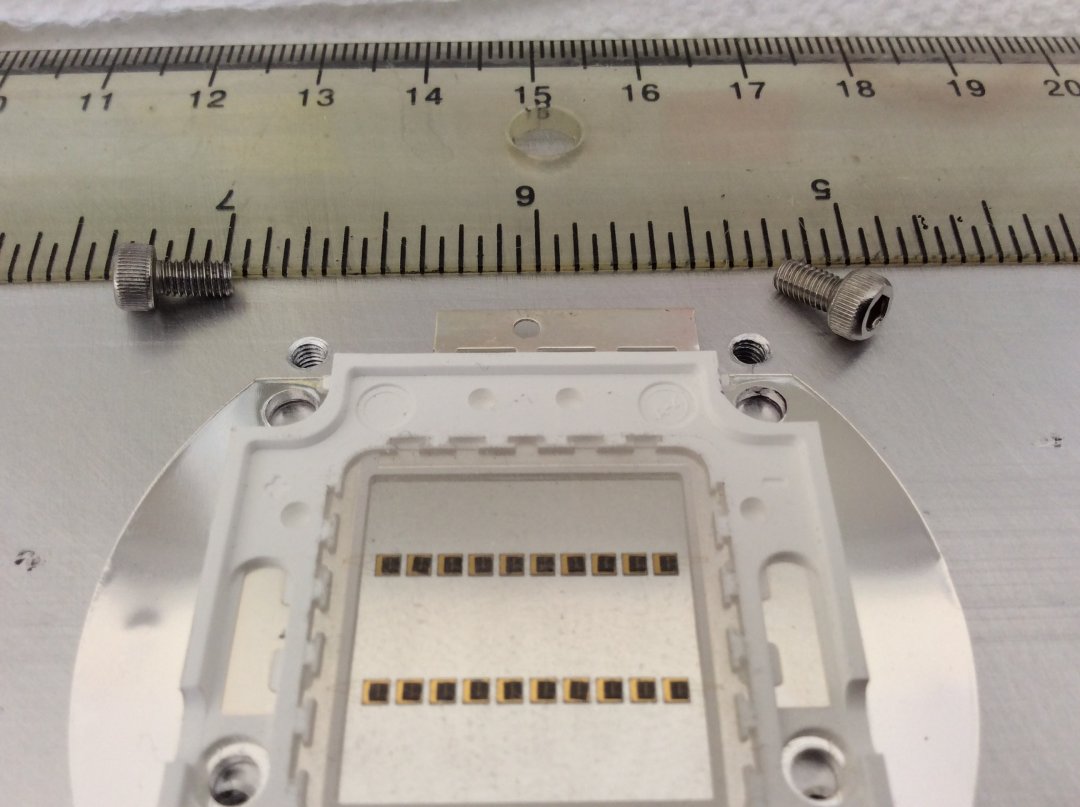

3mm screws i was tapping holes for in 1/4" copper & aluminum.

So easy to snap a tap that tiny (as i learned last yr). Using proper drill size takes forever, having to back out 1/8 turn after every 1/8 - 1/4 turn. I went 1 size bigger this time cause i had 32 holes to tap & holds plenty strong.

Made heatsinks from scrap for i.r leds for security cams in night mode to mount to soffit. Works great.

Rattle cans- how the heck did we ever use them lol.

3mm screws i was tapping holes for in 1/4" copper & aluminum.

So easy to snap a tap that tiny (as i learned last yr). Using proper drill size takes forever, having to back out 1/8 turn after every 1/8 - 1/4 turn. I went 1 size bigger this time cause i had 32 holes to tap & holds plenty strong.

Made heatsinks from scrap for i.r leds for security cams in night mode to mount to soffit. Works great.

Rattle cans- how the heck did we ever use them lol.

R

rusty musket

tap majic out of the question? engine oil always gave me burnt bits, whats your trick?

Mustang408

Member

I've used Boelube when I worked building 747s. No silocone, or wax.

The paste worked good to first coat the bit, then when the heat melted it and started to smoke, I would re-dip the bit in the cup of paste let it cool a second then rinse and repeat. I could drastically extend the life of the bit and get a quality hole ( every hole was checked with a gauge to pass QA).

Product description

Boelube is a specially formulated lubricant patented by Boeing Aerospace. Use it on drill bits, reamers, saw blades, taps & dies, boring tools, and any other application where smooth cutting action is required. The application of a small amount of Boelube, which is consumed in the metalworking process, will greatly improve tool life, surface finish, and hole quality. High film strength and lubricity and unique polar properties are the key to its ability to provide superior lubrication. Recommended for use on aluminum, titanium, inconel, stainless steel, graphite, composites, kevlar, and wood. Can also be used with other ferrous and non-ferrous metals. Completely non-toxic, non-irritating and biodegradable. Non-corrosive, non-flammable, chemically stable and free of halogens, heavy metals, suflur, phosporous, silicone, petroleum and paraffin wax.

https://www.amazon.com/Aircraft-Supply-Boelube-Paste-Medium/dp/B005VR9R6U

The paste worked good to first coat the bit, then when the heat melted it and started to smoke, I would re-dip the bit in the cup of paste let it cool a second then rinse and repeat. I could drastically extend the life of the bit and get a quality hole ( every hole was checked with a gauge to pass QA).

Product description

Boelube is a specially formulated lubricant patented by Boeing Aerospace. Use it on drill bits, reamers, saw blades, taps & dies, boring tools, and any other application where smooth cutting action is required. The application of a small amount of Boelube, which is consumed in the metalworking process, will greatly improve tool life, surface finish, and hole quality. High film strength and lubricity and unique polar properties are the key to its ability to provide superior lubrication. Recommended for use on aluminum, titanium, inconel, stainless steel, graphite, composites, kevlar, and wood. Can also be used with other ferrous and non-ferrous metals. Completely non-toxic, non-irritating and biodegradable. Non-corrosive, non-flammable, chemically stable and free of halogens, heavy metals, suflur, phosporous, silicone, petroleum and paraffin wax.

https://www.amazon.com/Aircraft-Supply-Boelube-Paste-Medium/dp/B005VR9R6U

Last edited:

EddieF

Top Banana

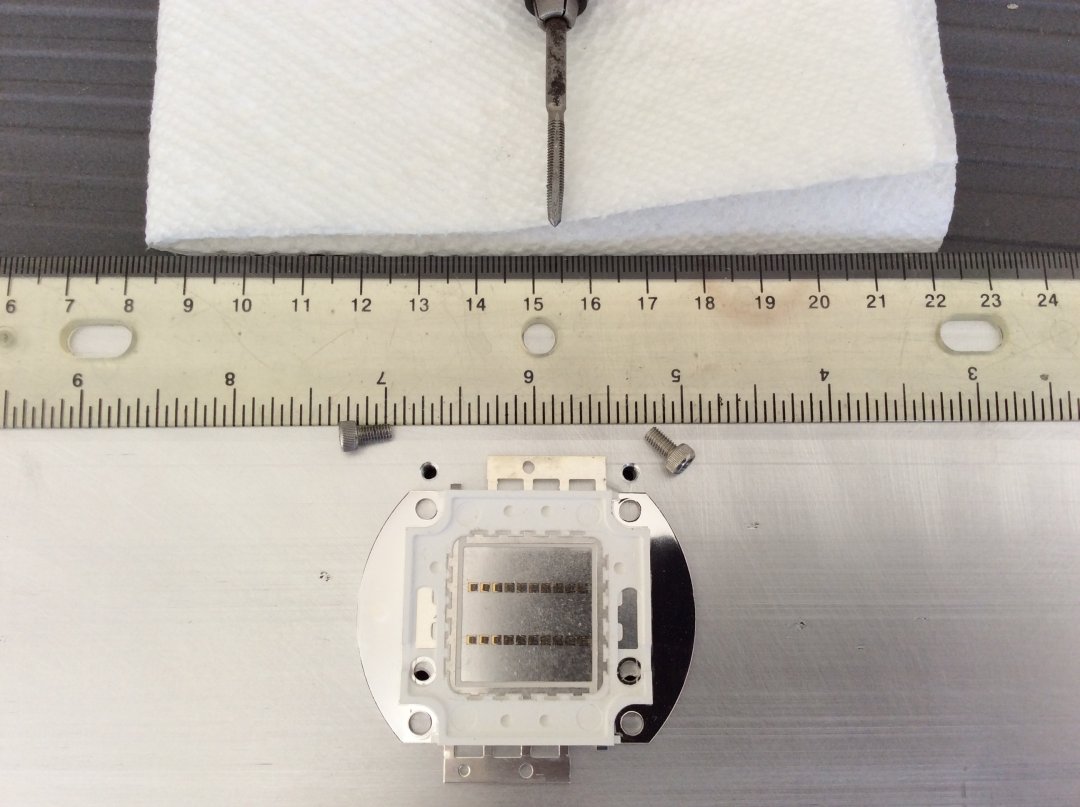

I got Boelube, small push-up pop style yesterday. Used it today. Might've helped with drilling, no oil, just rubbed tip of drill bit with it & rubbed flakey pieces in guide hole.

Looks like candle wax & is dry, flakes, not gel at all. Guessing it's good candle wax?

Tapping- tried it but had to put a drop of oil on tap once I started it and rubbed tip of tap on boelube before starting.

They tapped plenty good, threads more then good enough for anything this size. Aluminum plain 6061.

Not much wiggle room for error.

Looks like candle wax & is dry, flakes, not gel at all. Guessing it's good candle wax?

Tapping- tried it but had to put a drop of oil on tap once I started it and rubbed tip of tap on boelube before starting.

They tapped plenty good, threads more then good enough for anything this size. Aluminum plain 6061.

Not much wiggle room for error.

EddieF

Top Banana

Stuff works. Thankyou(s).

Yes i got diff type then suggested but it's good and was smaller, cheaper, quicker arrival.

What i got is their wax type. Seems to yeild tighter hole & threads shine compared to oil alone.

Tap doesn't wobble when backing out which is nice.

I still use a drop of oil after starting tap cause these are tight spaced threads. 15 in 1/4" i counted.

Happy camper.

Yes i got diff type then suggested but it's good and was smaller, cheaper, quicker arrival.

What i got is their wax type. Seems to yeild tighter hole & threads shine compared to oil alone.

Tap doesn't wobble when backing out which is nice.

I still use a drop of oil after starting tap cause these are tight spaced threads. 15 in 1/4" i counted.

Happy camper.