Hi all, I have this hood I'm wanting to convert, just wondering if anyone has any tips. I want to partially sink the aluminum stock into the hood rib about a 1/2". I plan on laying fiberglass mat in after I make my cuts, add the resin, then lay in the aluminum, then glass in some mat around the perimeter. Then add nutserts for the bolts. Sound ok or ??? Thanks for any help .

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Converting a pin on hood to a bolt on.

- Thread starter BB70

- Start date

Well, I was thinking of lightweight springs, but not definite. Looking at it more, kinda getting second thoughts about cutting on it and making it weak. I'm thinking of getting 1/2" thick alu plate and panel bond it on. I have the topside blocked to 220. Thanks for your reply.

1A Rock

Promoted Users

Man that sure looks like a real thin hood, what is it for? IMO it's going to take a lot make that hood hinge friendly. I can see where you might spend an awful lot of effort and be unhappy with the results. All the glass hoods I've seen that were meant to hinged where really thick and heavy. We put a swap meet used Harwood on my son's 67 Camaro and it is MUCH thicker than yours appears. Good luck

Hi 1A Rock, its for a 70 GTO. I could lift it off myself and put it on the roof, on a blanket, but since I'm painting the car I want to get away from that. It weighs more now, took a few of rounds of slick sand and hi build to get it level on top. I think cutting on it is out now.

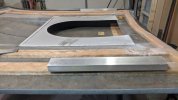

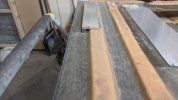

Just thought to show what I wound up doing.I used some 1/2" plate for the hinge to bolt to. I read my notes wrong on where the hinge bolts should be, which caused the overhang off of the rib. So I got some 5/8 steel rod to put between the overhang and the hood. I made up some end caps for looks, then I used 3m 8115 to put it all together, and put a reciever for the prop rod on the front. Then scuffed it all up and put 2 coats of epoxy primer on it. Thanks to all that chimed in for the help. Now to finish blocking the top and paint it.

Attachments

jlcustomz

evil painter

I modified my busted Harwood hood back in 2010 with hammerformed aluminum side perimeter strips with punched & flared holes. It's strong enough for my parallelogram lift & tilt back mechanism.

What you did should be fine. You will see some dampness shadowing in some weather conditions such as early on a damp morning where the bracing is, but that's normal.

What you did should be fine. You will see some dampness shadowing in some weather conditions such as early on a damp morning where the bracing is, but that's normal.

jlcustomz

evil painter

Also thought I'd mention I think that hood props look cheap on hot rods, but everyone is entitled to their own opinion as well as restricted by time, money , and capabilities.

That being said, gas shocks I feel give a better function than springs giving a more consistent and lineal amount of push throughout it's range of motion than a spring, which gets weaker where you need the most strength in full up position. Biggest drawback to shocks is their approx 5 to 15 year lifespan.

With either springs or shocks, mounting positions & length of motion greatly affect performance and what strength & length of part to use. Further away from hinge pivot point requires less strength of part, but more travel,,, closer needs more strength & less travel. shocks can be set up directly from hood to fender with longer travel weaker shocks or on the hinges with shorter stronger shocks.

While starting from scratch takes a little bit of understanding as well as possible trial & error, this sort of thing has been done by many that could be copied off of a google search , as well as what is setup on these expensive billet hinges with shocks for your model & fiberglass hood choice.

Just a few thoughts. Also this is something that could always be done some other time.

That being said, gas shocks I feel give a better function than springs giving a more consistent and lineal amount of push throughout it's range of motion than a spring, which gets weaker where you need the most strength in full up position. Biggest drawback to shocks is their approx 5 to 15 year lifespan.

With either springs or shocks, mounting positions & length of motion greatly affect performance and what strength & length of part to use. Further away from hinge pivot point requires less strength of part, but more travel,,, closer needs more strength & less travel. shocks can be set up directly from hood to fender with longer travel weaker shocks or on the hinges with shorter stronger shocks.

While starting from scratch takes a little bit of understanding as well as possible trial & error, this sort of thing has been done by many that could be copied off of a google search , as well as what is setup on these expensive billet hinges with shocks for your model & fiberglass hood choice.

Just a few thoughts. Also this is something that could always be done some other time.

Dean Jenkins

Promoted Users

@jlcustomz comment got me thinking.

No idea how heavy your hood is, but many newer cars with composite hoods don't have big traditional springs, just gas struts built into the hinge.

Here are the hinge/strut units I used for the custom "trunk" on my el Camino.

Just wandered around local pick-n-pull till I found the right ones.

Don't know if something like that would work for you, but thought I'd toss it out.

No idea how heavy your hood is, but many newer cars with composite hoods don't have big traditional springs, just gas struts built into the hinge.

Here are the hinge/strut units I used for the custom "trunk" on my el Camino.

Just wandered around local pick-n-pull till I found the right ones.

Don't know if something like that would work for you, but thought I'd toss it out.