If you are plug welding, epoxy prime both parts inside and use modified bit to clean off paint inside plug weld holes once they are clamped together and weld. If you are spot welding, epoxy prime both parts inside, mock up and mark for spot weld locations and clean paint off per the following:

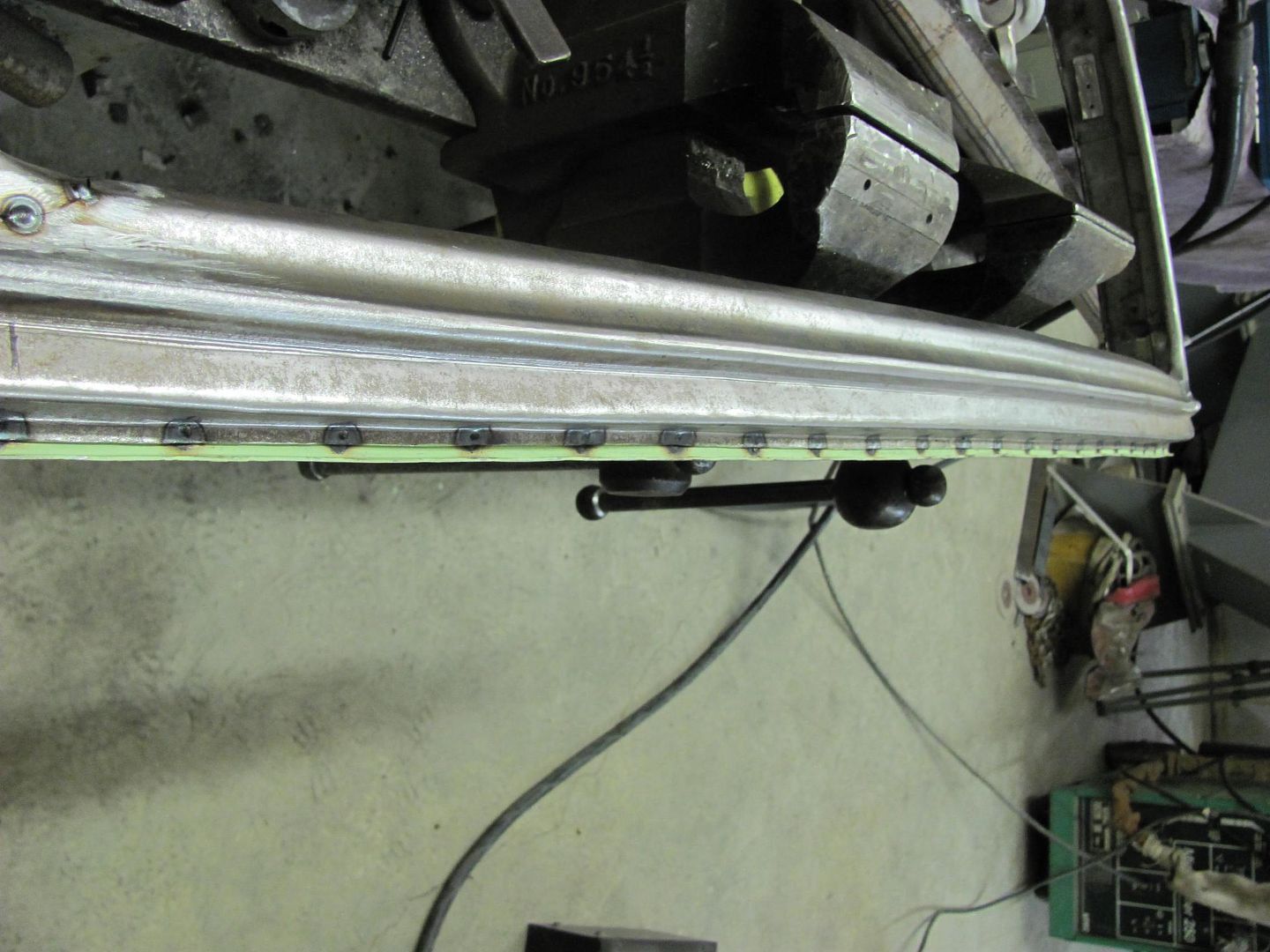

In order to use the spot welder along the bottom seam, we needed to clean off some epoxy primer where the spot welds would be located. Used and even spacing of 2" and marked both flanges...

In order to remove as little epoxy primer as possible, we decided to use the modified plug weld drill bit (the flattened one) over all the errant marks a roloc sander would make. In order that the flat drill bit didn't walk all over the place, another specialized tool was made....

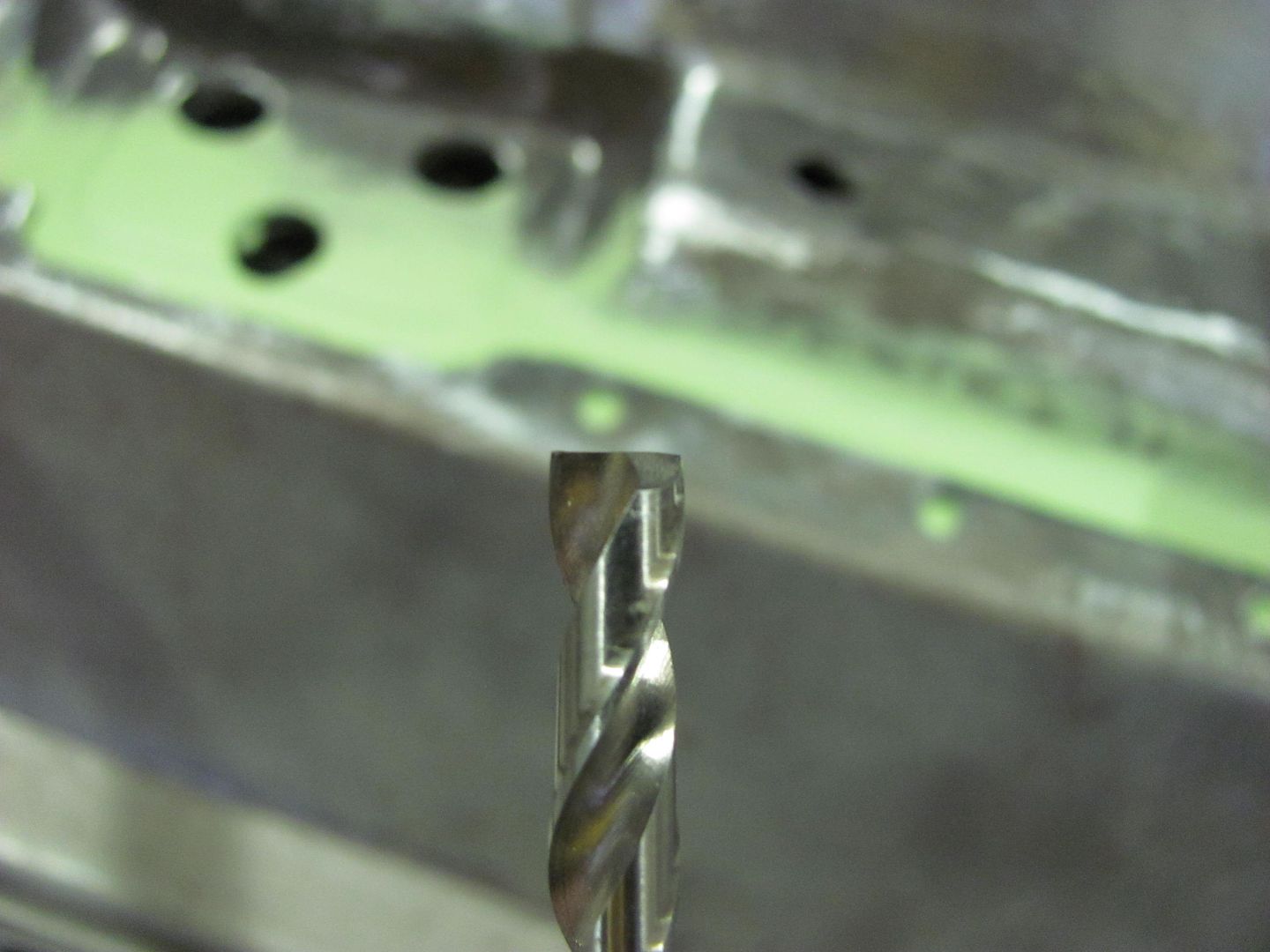

Here's another close up of the modified bit...

this is the same size drill bit I used for plug weld holes is flattened and backfaced to resemble an end mill cutter.

.....and the "prepped" flanges...

Flanges spot welded together...

Prep remainder and epoxy the outside...