DavidL

Promoted Users

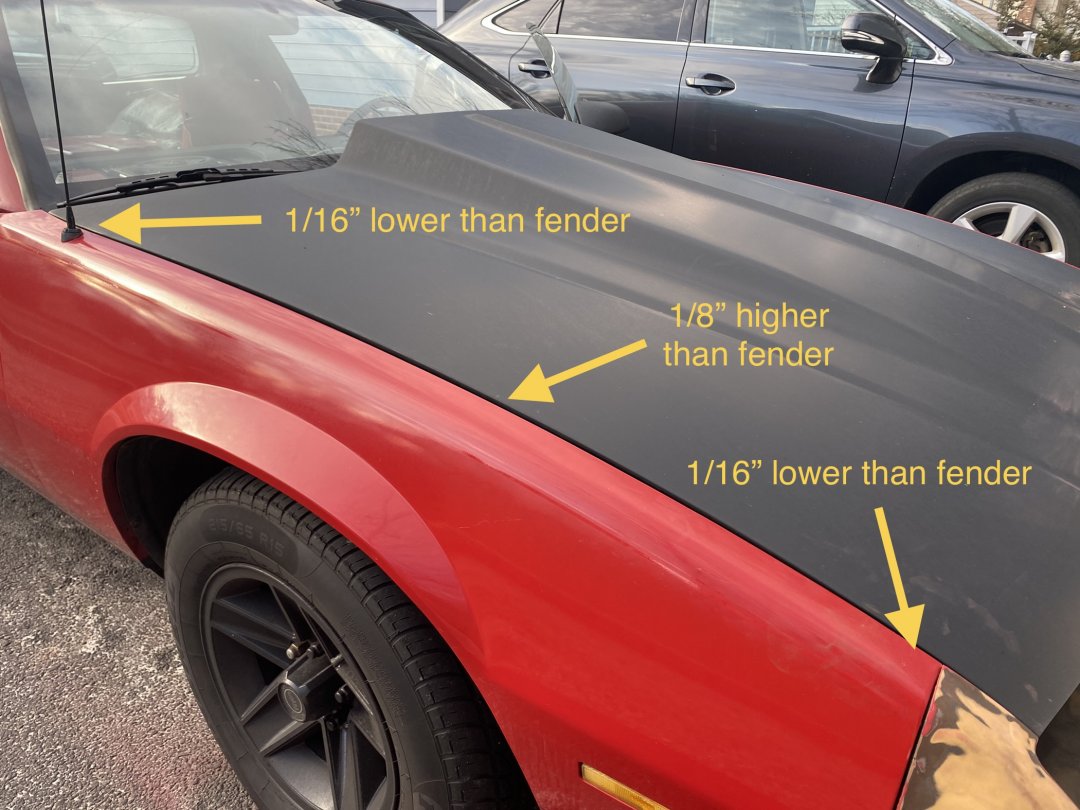

I’m prepping an aftermarket hood and the on the passenger side the profile of the hood doesn’t match the curve of the top of fender. It’s slightly higher than the fender in the middle and lower than the fender at the front and back (pic below). The fit on the driver side is perfect.

There is a 3/4” standing seam on the edge of the hood. Could I use a metal stretcher on that standing seam to decrease the arc of the hood? Or cut a series of vertical cuts through that seam to allow enough flex to adjust the curve then weld them up? Or any other suggestions?

Picture of the seam:

There is a 3/4” standing seam on the edge of the hood. Could I use a metal stretcher on that standing seam to decrease the arc of the hood? Or cut a series of vertical cuts through that seam to allow enough flex to adjust the curve then weld them up? Or any other suggestions?

Picture of the seam: