rustover

Member

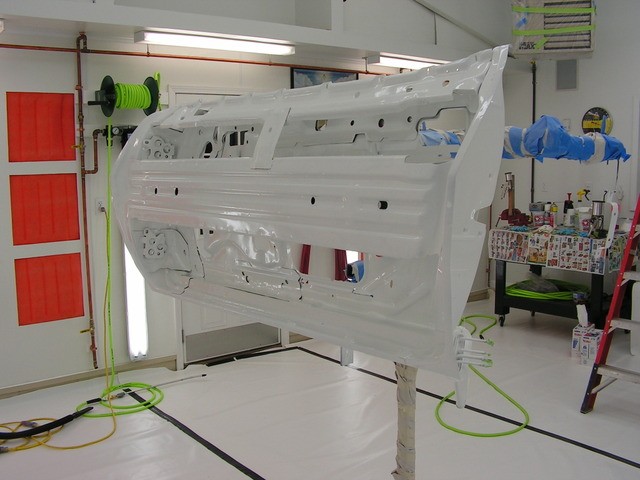

Chipping away at removing the trunk pan. I purchased a air hammer, and I have to say I really like it when it comes to separating panels.

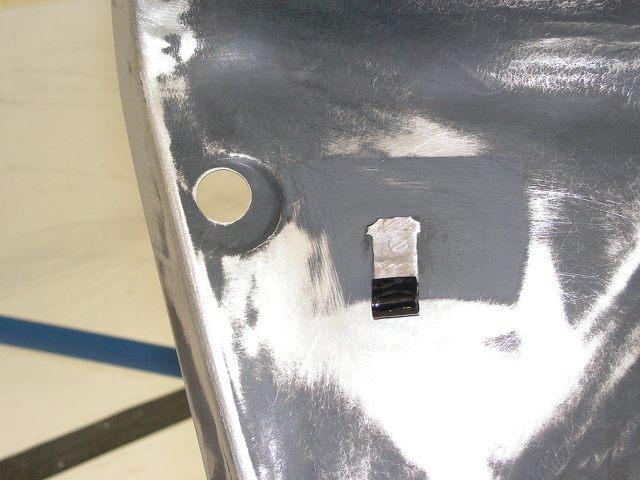

I got the undercoating off the right side inner fender.

I will have to put in one small patch.

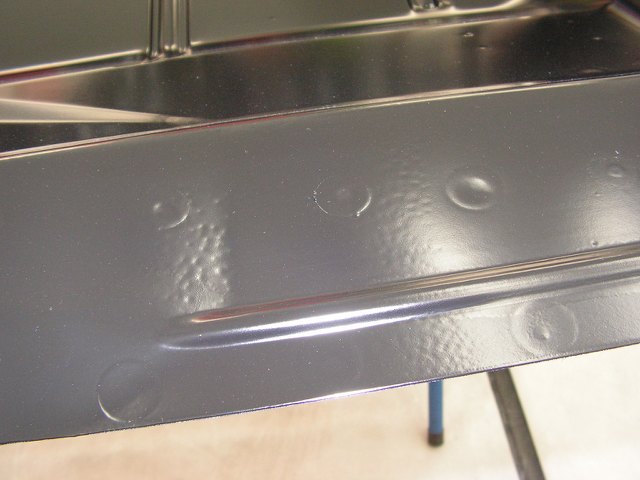

As far as the trunk goes, I'm still waiting on the replacement pan. I removed the center section. The air hammer made quick work of this.

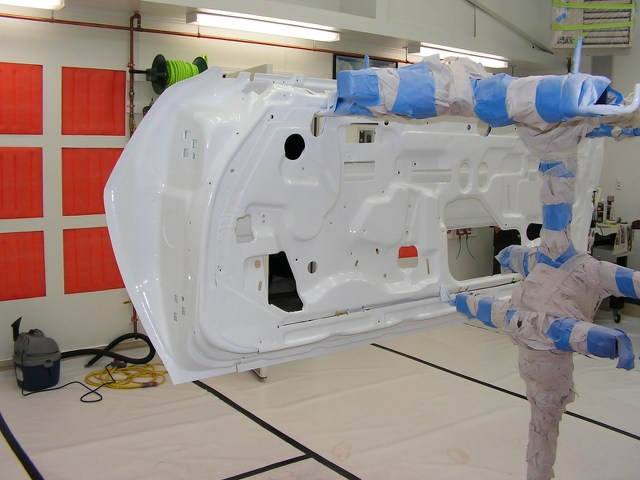

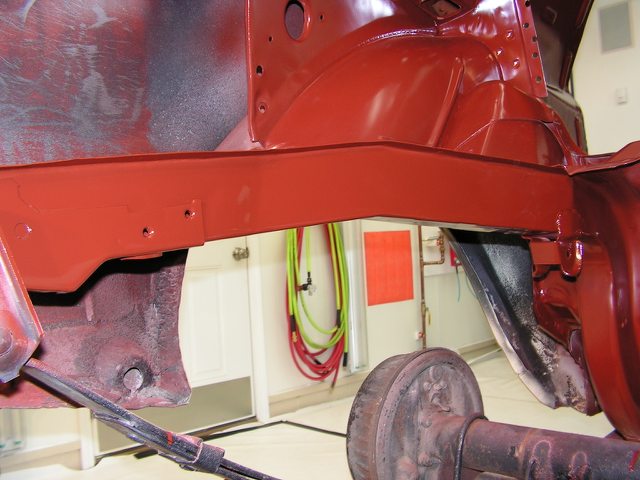

Today, I started removing the left side over the frame rails and up against the drop off and shock tower area. This was very slow. The spot welds were really tough, I ended up grinding them down before using the hammer. I didn't want to destroy anything. I did manage to tear the drop off up near the cross rail. Its getting replaced with the quarters, but I want it there to fit the new pan. This is a very tight area to work due to the frame rails.

Here is my rough cut of the shock tower area. I'm planning on splicing somewhere to this part of the panel. Its a rough cut, but its close.

Still got to do the right side.

I got the undercoating off the right side inner fender.

I will have to put in one small patch.

As far as the trunk goes, I'm still waiting on the replacement pan. I removed the center section. The air hammer made quick work of this.

Today, I started removing the left side over the frame rails and up against the drop off and shock tower area. This was very slow. The spot welds were really tough, I ended up grinding them down before using the hammer. I didn't want to destroy anything. I did manage to tear the drop off up near the cross rail. Its getting replaced with the quarters, but I want it there to fit the new pan. This is a very tight area to work due to the frame rails.

Here is my rough cut of the shock tower area. I'm planning on splicing somewhere to this part of the panel. Its a rough cut, but its close.

Still got to do the right side.